34

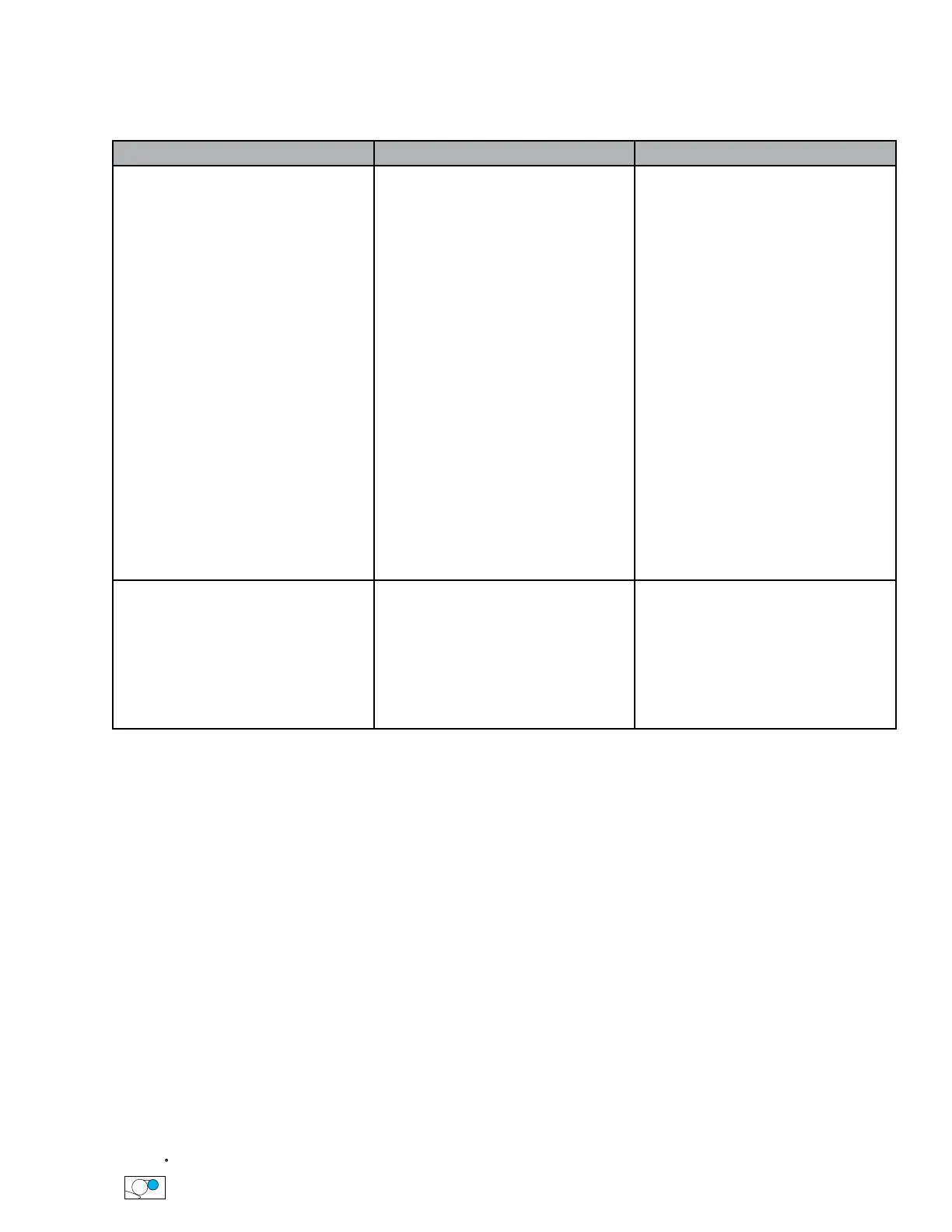

Troubleshooting Guidelines

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY

Coating nish appears “Orange

Peel” or not smooth

a. Too much coating being

applied

b. Coating viscosity is too thick

c. Coating stored in a cold

room

d. Belt speed is too fast

e. “Optional” Oscillating roller

not installed

a. Increase Form to Metering

roller pressure

b. Change to a thinner coating,

making sure that the coating

is correct for the printer type

and substrate you are using

c. For best results, store the

coating in a climate control

room 70-90°F (21-32°C)

d. Decrease belt speed

e.

The appearance of most all

coatings can be improved

with the addition of the

“Optional” Oscillating roller.

(See the Komplete Roller

section of the Con-

sumables page or contact

Uninet Customer Service

for more information)

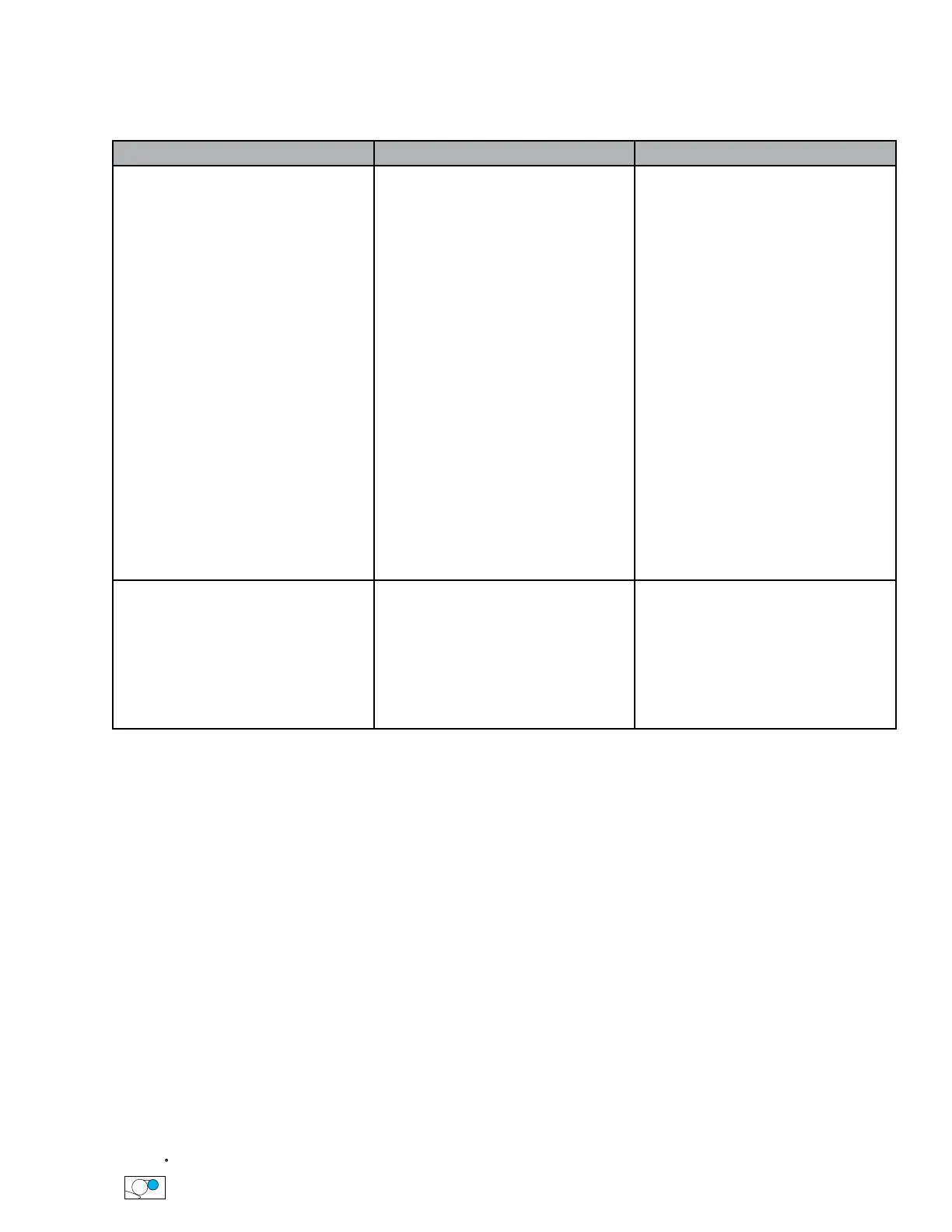

Coating scratching off a. Improper coating solution

b. Not enough curing power

c. Belt speed is too fast

d. Too much curing

e. Old UV Bulb

a. Make sure coating is correct

for print type and substrate

b. Increase UV intensity

c. Decrease belt speed

d. Decrease UV intensity

e. Replace UV Bulb

Loading...

Loading...