Side 11 af 26 UR-FK 2011

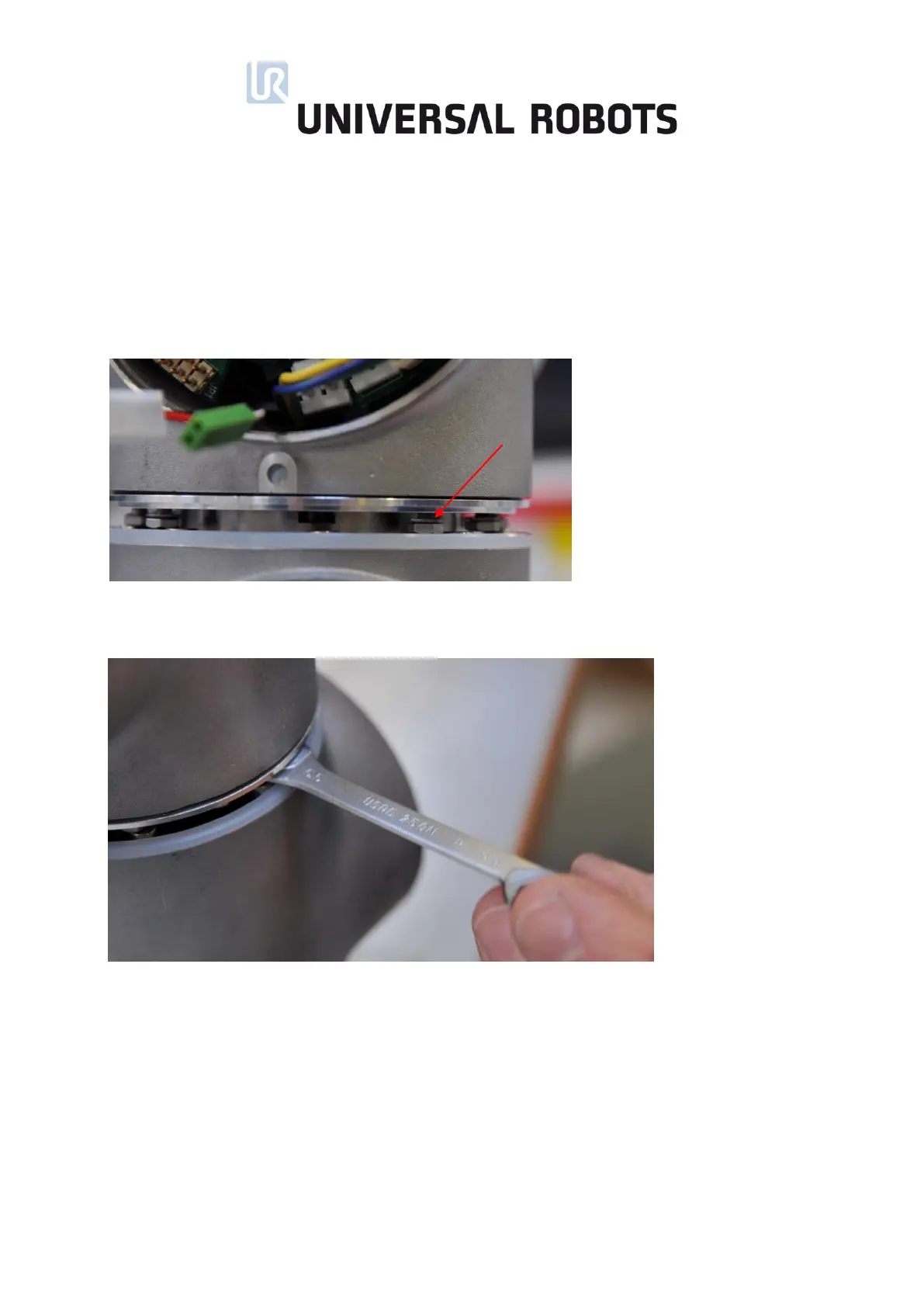

It is important that the washers are also pushed through, otherwise the joints may

not rotate into place. The grease filling holes must be properly aligned once the

joints have been rotated into position. There is a guide groove opposite the grease

filling section and it is important that this groove falls into place when the joints

are rotated into position.

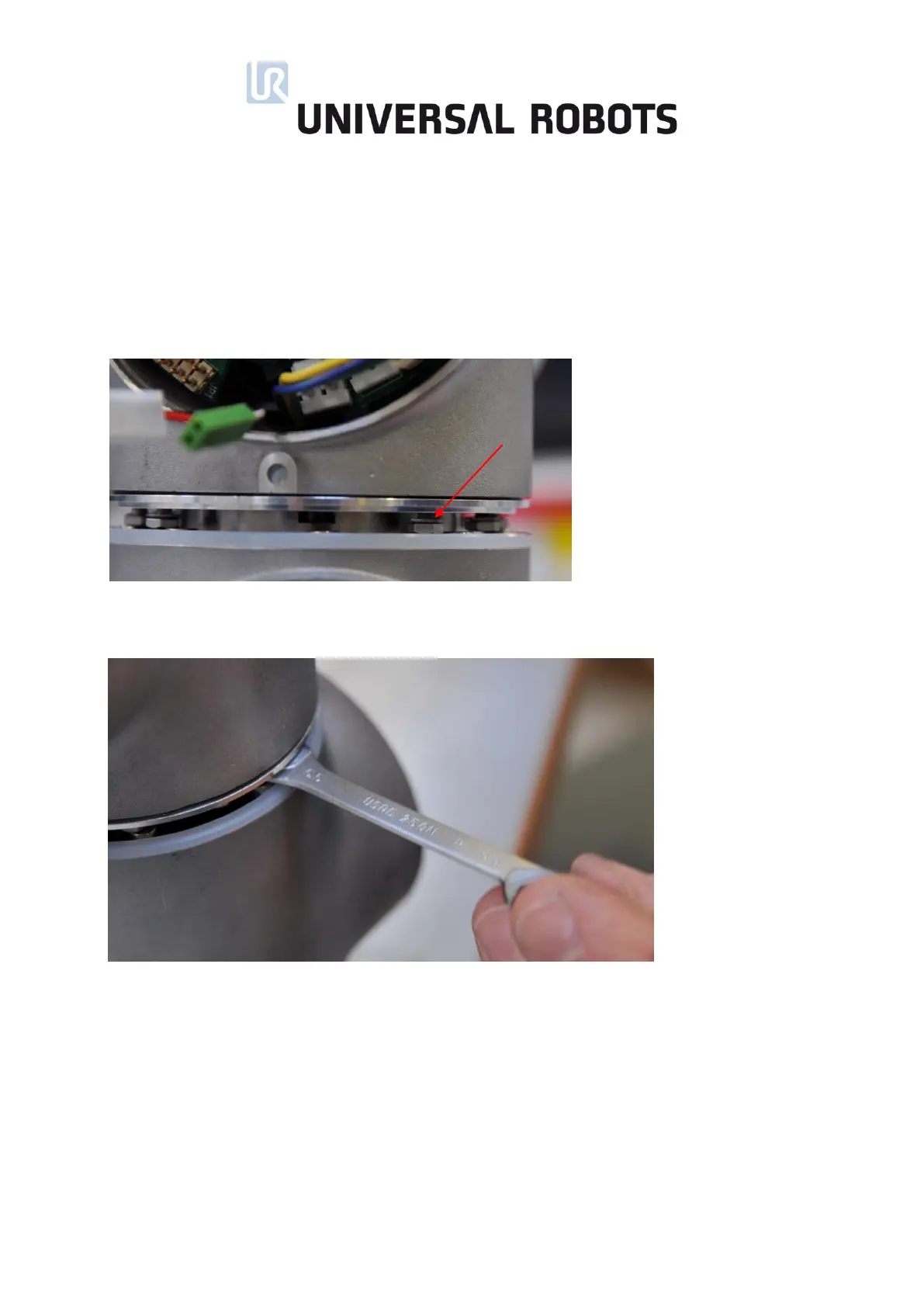

Tighten the screws alternately a little at a time until all screws are tightened to the

torque set out below.

Size 1: tighten screws to 0.5 Nm and then 1.0 Nm

Size 3: tighten screws to 1.2 Nm and then 2.4 Nm

A special torque wrench is recommended for this procedure – see the spare parts

list on page 18 for item number.

Loading...

Loading...