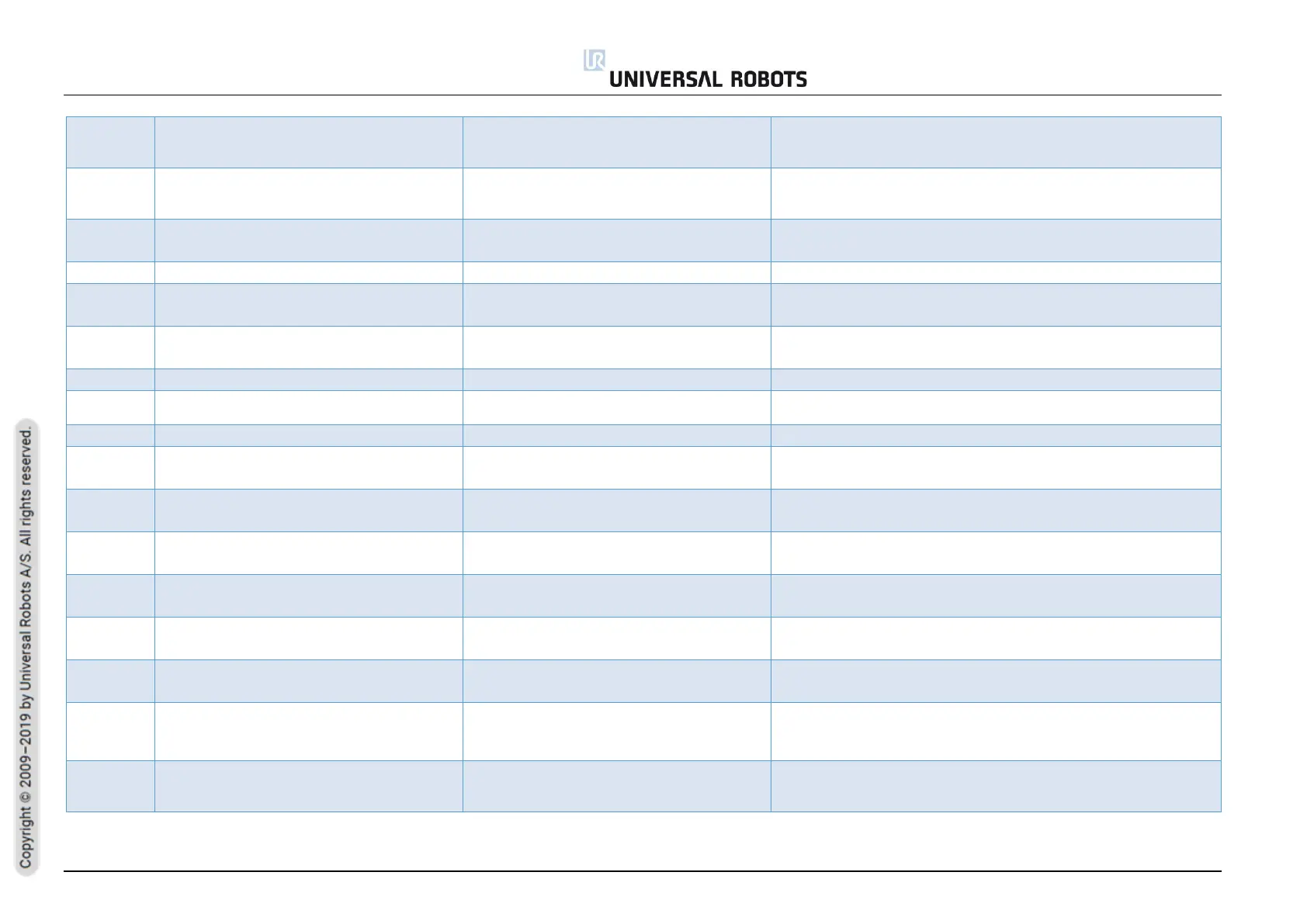

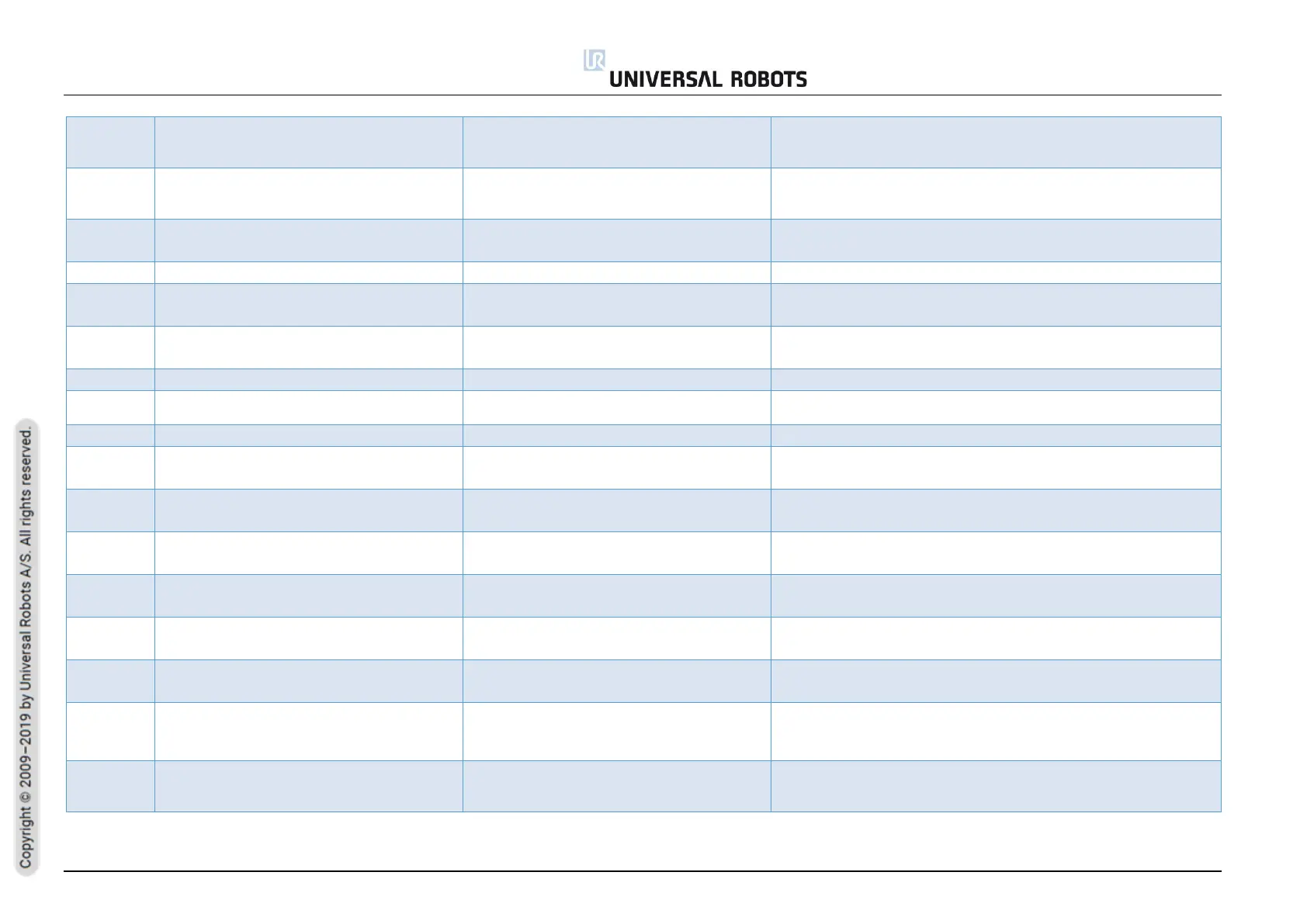

All rights reserved 113 Service Manual e-Series (EN) 1.1.8

Inconsistency between target position and

speed

Controller is detecting that position in current

cycle has changed much more than it should

based on expected joint speed.

a) Either an incorrect payload is mounted, or an external force is

pushing the robot.

b) Check TCP configuration, payload and mounting settings.

The program contains motions that are not

ramped correctly down

To abort a motion, use \stopj\” or \”stopl\” script commands to

generate a smooth deceleration before using \”wait\”. Avoid aborting

motions between waypoints with blend”

Robot has not stopped in the allowed reaction

and braking time

Robot program resulted in invalid setpoint

Blending failed and resulted in an invalid

setpoint

Try changing the blend radius or contact technical support

Robot approaching singularity – Acceleration

threshold failed

Target speed does not match target position

Inconsistency between target position and

speed

Target joint speed does not match target joint

position change – Base

Target joint speed does not match target joint

position change – Shoulder

Target joint speed does not match target joint

position change – Elbow

Target joint speed does not match target joint

position change – Wrist 1

Target joint speed does not match target joint

position change – Wrist 2

Target joint speed does not match target joint

position change – Wrist 3

Fieldbus input disconnected

Check fieldbus connections (RTDE, ModBus, EtherNet/IP and

Profinet) or disable the fieldbus in the installation. Check RTDE

watchdog feature. Check if a URCap is using this feature.

An assert was executed.

Notice: The functionality is exclusively used for

testing purposes.

Loading...

Loading...