Page 18

49379902 Rev. G Radial 8 & 88 Operation Reference Manual

This Document Supports IM-UPS 5.0 and Higher

Pneumatic Controls and Indicators

The pneumatic system for the inserter and sequencer has a regulator that is

factory set at 80 psi and a locking element installed. The regulator is located

on the right wall of the front, center compartment of the base cabinet.

A low air pressure sensor senses line air pressure. If the air pressure drops

below 60psi, the low air pressure sensor shuts the machine down. This

pressure sensor is not adjustable. Insufficient flow can cause a pressure drop

that will activate the sensor.

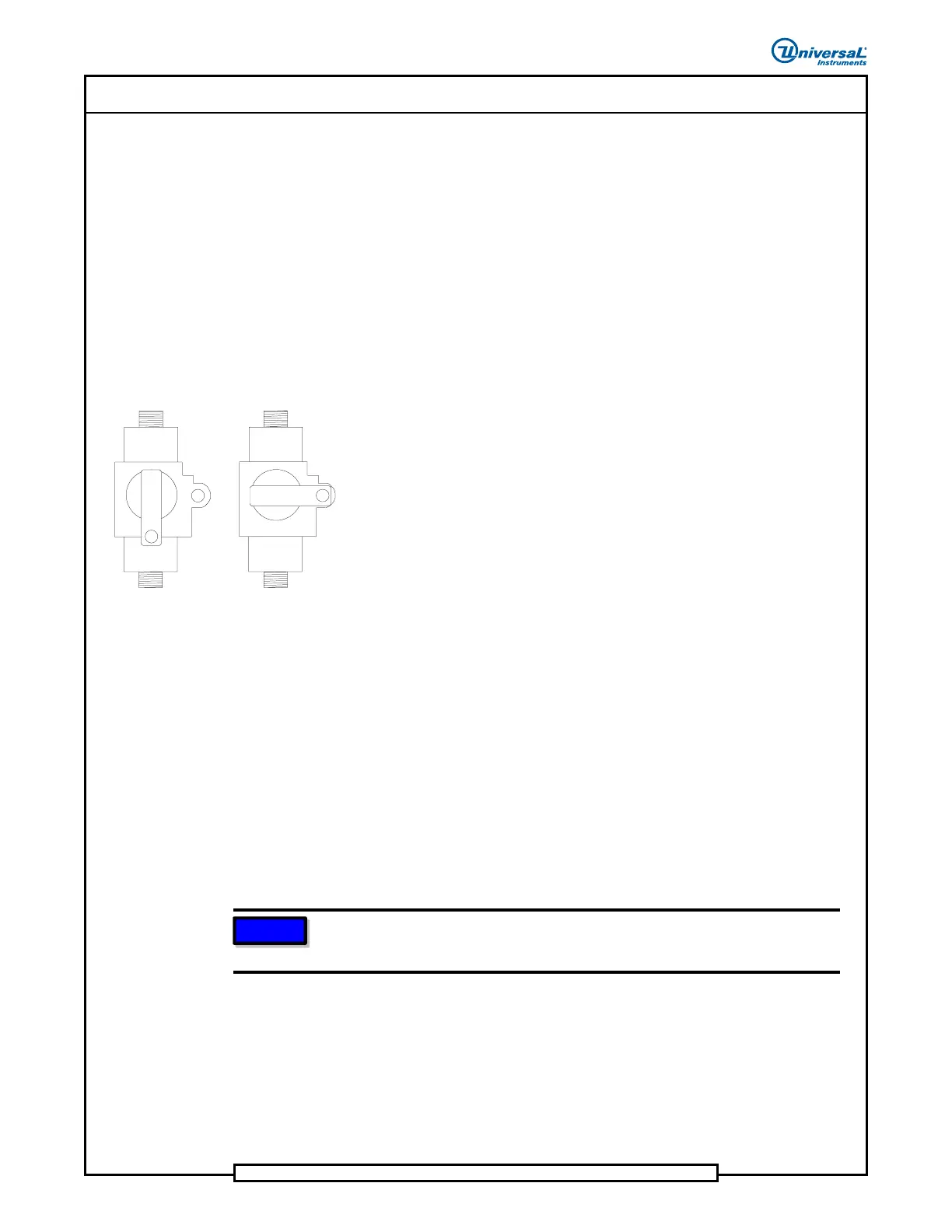

Lockout Valve

LOCKOUT

VALVE OPEN

LOCKOUT

VALVE CLOSED -

LOCKOUT POSITION

The pneumatic lockout valve removes or applies pressurized air to the

machine.

Pneumatic Lockout / Tagout

When the pneumatic lockout valve is closed, a lockout / tagout device can be

applied to prevent accidental opening of the valve. Refer to your company's

policy regarding the proper procedures to be followed during machine repair.

This machine is equipped with a pneumatic lockout/tagout system. The

pneumatic lockout/tagout valve is used to prevent pressurized air from

reaching the machine. When the lockout/tagout system is used to prevent

pressurized air from reaching the machine, the valve is positioned so that it

can be locked and or tagged to notify personnel that work is being done on

the machine. All tags or locks shall meet your company safety standards for

this type of device.

Machine Configuration

Before attempting to operate the machine, IM-UPS must be configured to

match the hardware configuration of the machine.

NOTE

The machine configuration is defined at the factory and should not have

to be defined or changed unless the hardware configuration changes.

The machine configuration window can be used to configure the current

machine or to define a machine configuration template. The template is used

by the Product Editor for creating products at a desktop PC. The Product

Editor assumes the characteristics of the selected machine.

There are minor differences between using the window for configuring the

machine or creating a template. These differences are noted in the procedure.

Loading...

Loading...