Page 10 113100-000 | MX15 / MX19 - Operator Manual

Maintenance

M

AINTENANCE

WARNING

!

!

Never perform service while the platform is elevated without first blocking the elevating assembly.

DO NOT stand in the elevating assembly area while deploying or storing the brace.

B

LOCKING

T

HE

E

LEVATING

A

SSEMBLY

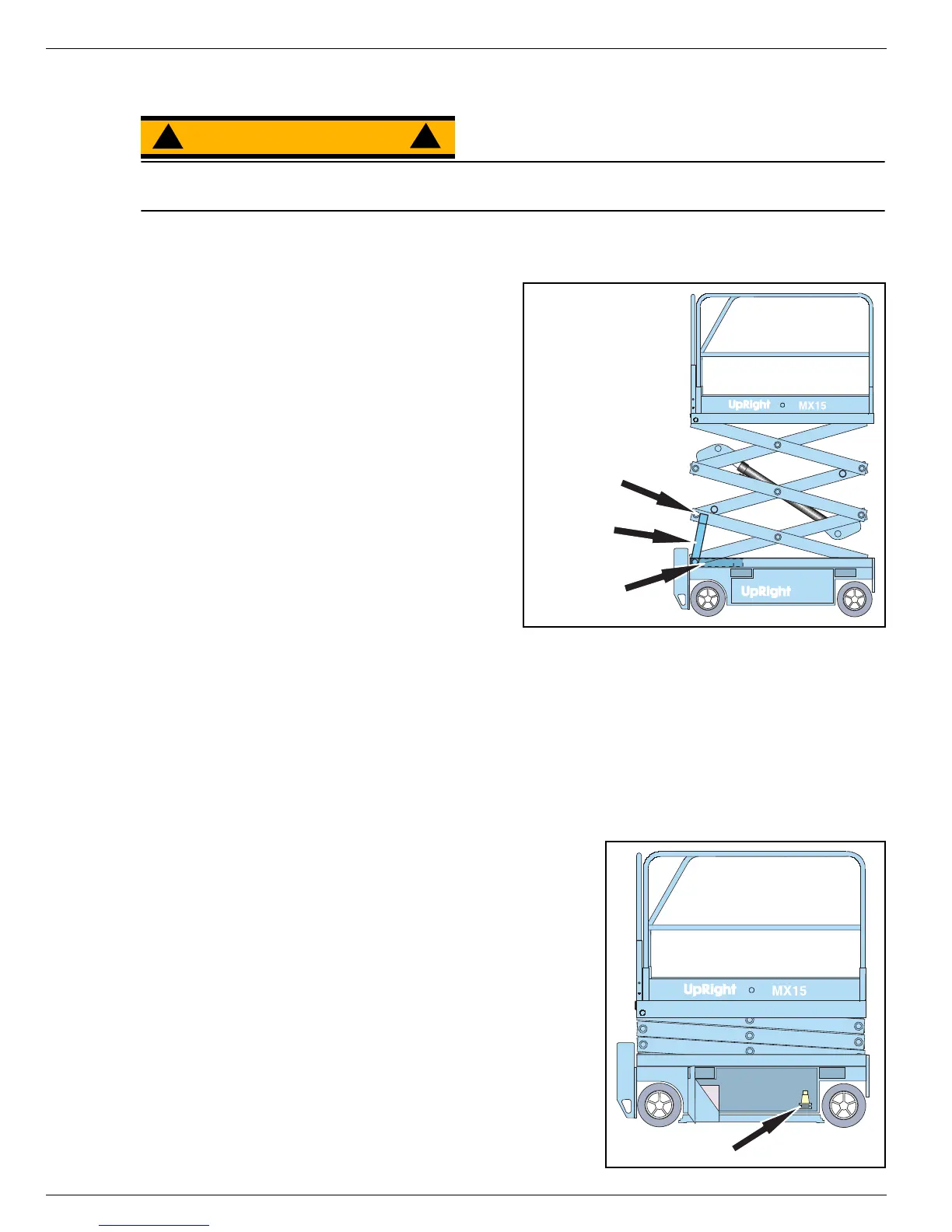

Figure 7:

Elevating Assembly Brace

E

LEVATING

A

SSEMBLY

B

RACE

I

NSTALLATION

1. Park the machine on a firm, level surface. Com-

pletely unload the platform before deploying the

Elevating Assembly Brace.

2. Verify that the Chassis and Platform Emergency

Stop Switches are ON by pulling each button

out.

3. Turn and hold the Chassis Key Switch to

CHASSIS. Push the Chassis Lift/Lower Switch to

UP and elevate the platform approximately

2,1 m (7ft.).

4. Rotate the Elevating Assembly Brace to a verti-

cal position.

5. Carefully lower the platform until the end of the

Elevating Assembly Arm Weldment rests on the

Brace.

E

LEVATING

A

SSEMBLY

B

RACE

S

TORAGE

1. While holding the Brace, slowly raise the platform using the Chassis Controls until the end of the Elevat-

ing Assembly Arm Weldment clears the Elevating Assembly Brace.

2. Rotate the Elevating Assembly Brace forward to rest on the Chassis.

3. Push the Chassis Lift/Lower Switch to LOWER and completely lower the platform.

L

EVEL

S

ENSOR

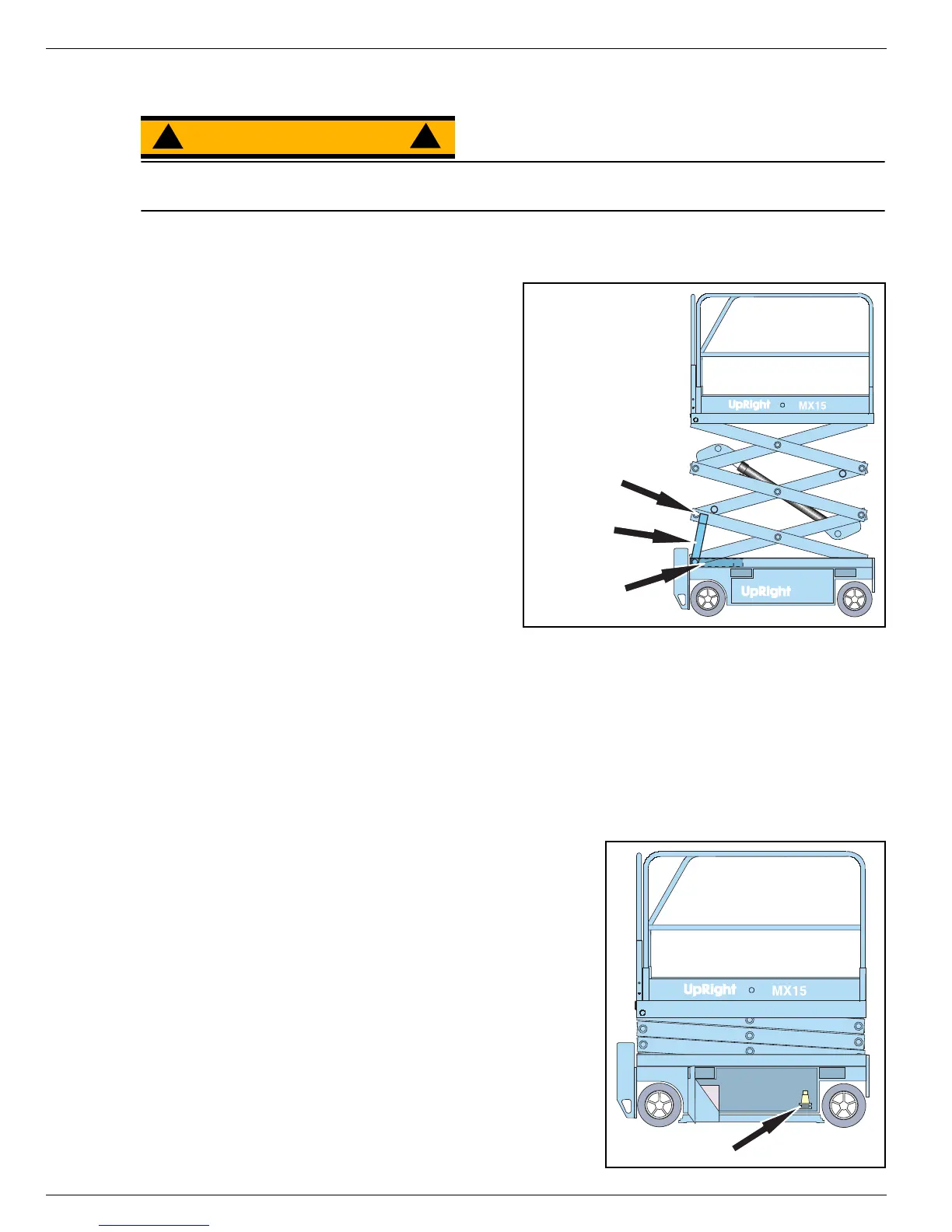

Figure 8:

Level Sensor Location

The Level Sensor Is located inside the chassis. To verify the

sensor is working properly there are two LED's under the sen-

sor; green indicates the sensor is ON (has power), red indi-

cates the sensor is LEVEL.

T

ESTING

THE

L

EVEL

S

ENSOR

1. Place machine on firm level surface.

2. Open the door.

3. Push and hold the sensor off of level.

4. Push the Chassis Lift Switch to the UP position.

• The alarm should sound, and the platform should not lift.

5. Close and latch the door.

Elevating

Assembly Arm

Weldment

Brace

Installed

Brace

Stored

Level Sensor

Loading...

Loading...