Long Term Storage Section 1 - General Information

Page 1-18 Service Manual

F

LOOR

L

OADING

S

PECIFICATIONS

Personnel Lift Machines

Small Slab Machines

1-13 L

ONG

T

ERM

S

TORAGE

NOTE:

Do not drain the hydraulic system prior to long term storage.

If the machine is to be placed in long term storage, follow these recommended preservation procedures.

P

RESERVATION

1. Clean painted surfaces. If paint is damaged, repaint.

2. Fill the hydraulic reservoir to operating level.

IMPORTANT: Do not fill the hydraulic reservoir while the platform is elevated.

3. Coat exposed portions of cylinder rods with a preservative such as multipurpose grease and wrap with

a barrier material.

4. Coat all exposed unpainted metal surfaces with preservative.

5. Internal Combustion Models: Service the engine according to the manufacturers recommendations.

6. Electric And BiEnergy Models: Remove the batteries and place them in alternative service.

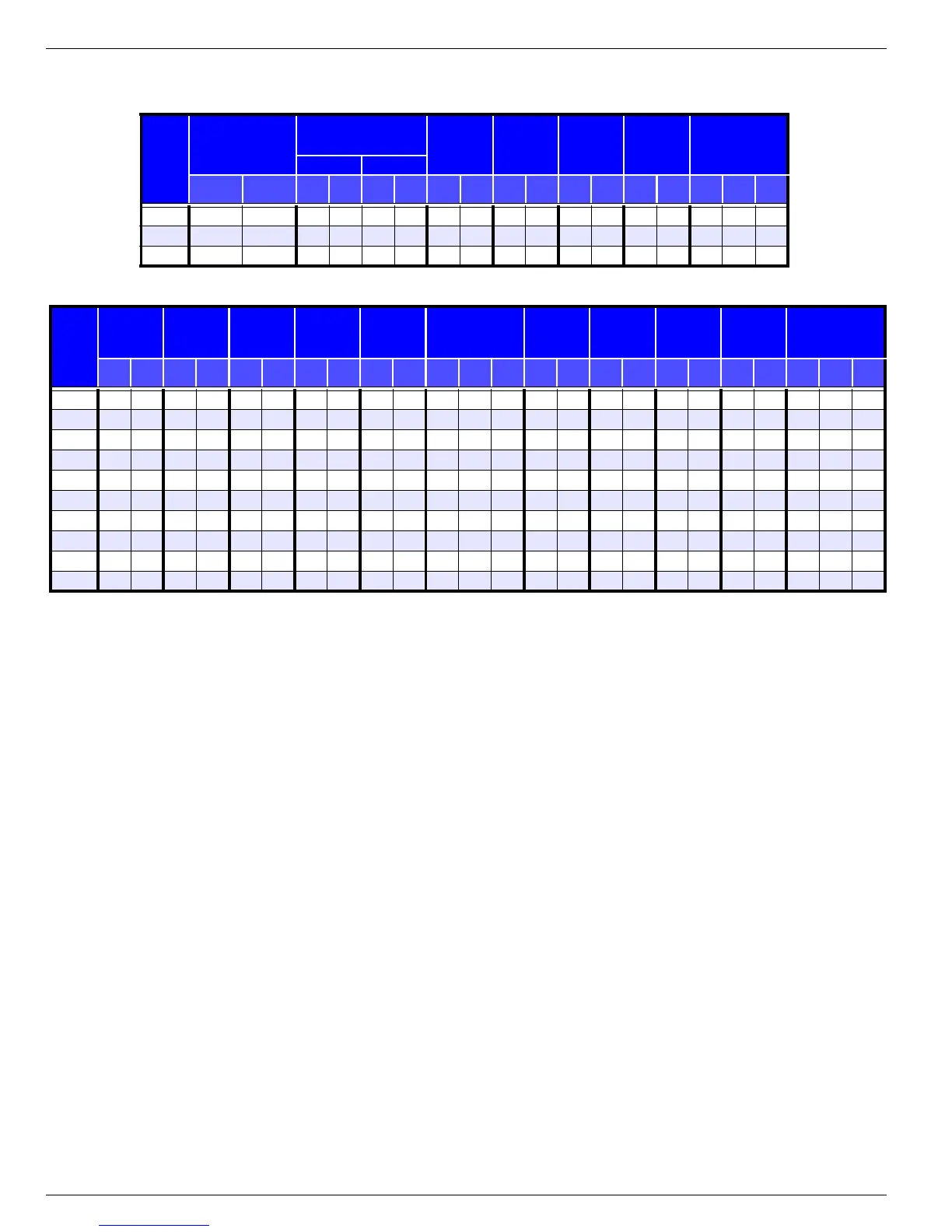

MODEL

Installed Outrigger

Area

(Length X Width)

Unit Weight

Platform

Capacity

Occupied

Floor Area

Occupied

Floor

Pressure

(uniform)

Outrigger

Pad Area

Maximun Localized

Pressure

(each pad,)

AC Units DC Units

in. cm lbs. kg lbs. kg lbs. kg in.² m² psf kPa in.² cm² psi kPa

kg/

cm²

UL25 59 x 56 105 x 142 770 349 810 367 350 159 3304 2,13 50 2,39 12.57 81 23 1,62 159

UL32 81 x 78 206 x 198 920 417 960 435 300 136 6318 4,08 29 1,39 12.57 81 25 1,76 172

UL40 92 x 89 234 x 226 990 449 1030 467 300 136 8188 5,69 23 1,1 12.57 81 26 1,83 179

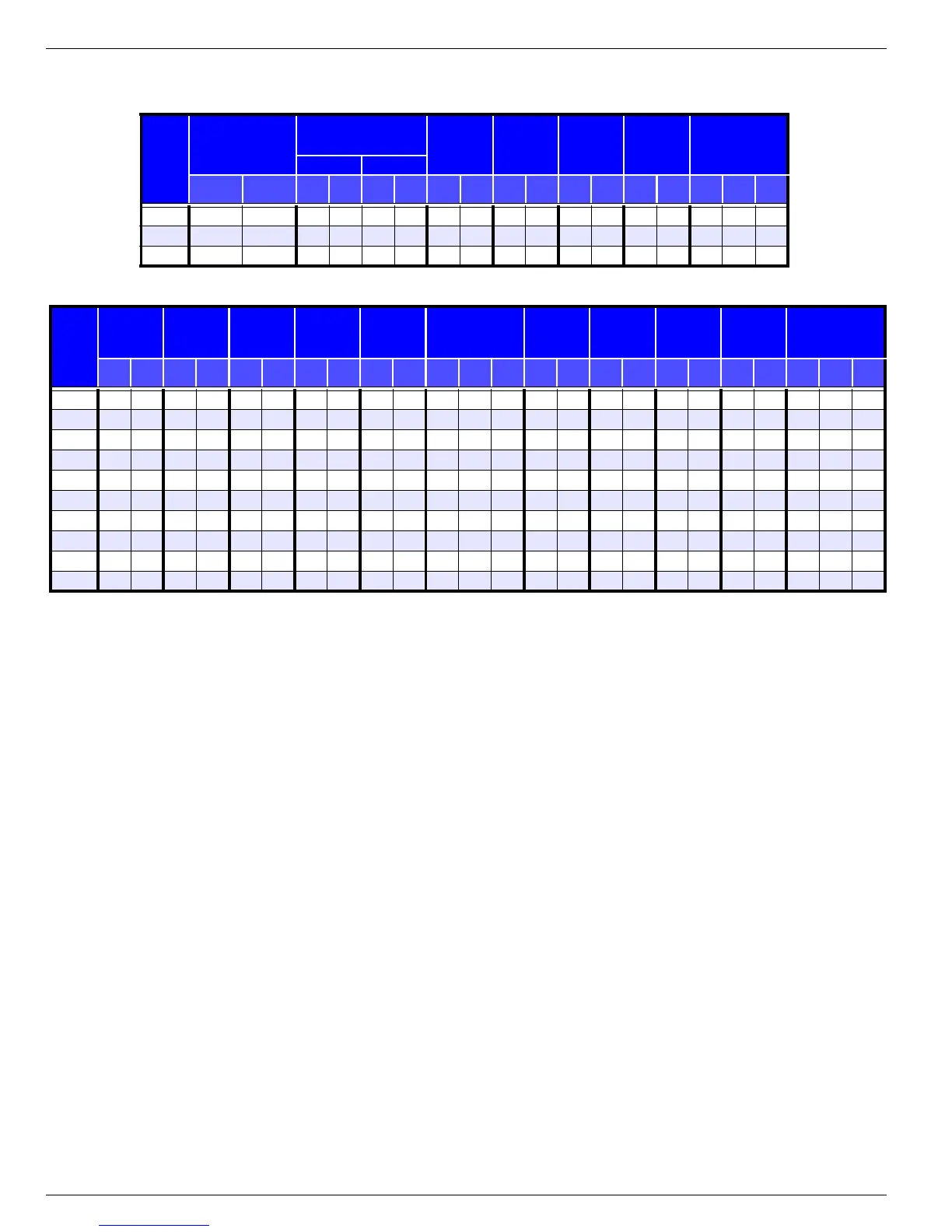

MODEL

Chassis

Length

(excluding

Ladder)

Vehicle

Width

Vehicle

Weight

Platform

Capacity

Occupied

Floor Area

Occupied Floor

Pressure (uniform)

Maximum

Tire Load

(including

rated load)

Maximum

Axle Load

(including

rated load)

Tire Width

Tire Contact

Area

Maximun Localized

Pressure

(each tire, platform

extended)

in. m in. m lbs. kg lbs. kg in.² m² psf kPa

kg/

cm²

lbs. kg lbs. kg in. cm in.² cm² psi kPa

kg/

cm²

TM12 53.5 1,36 30.0 0,75 2209 1002 500 227 1602 1,03 243 11,63 0,118 677 307 1354 614 2.75 7 7.9 50,3 85.7 591 6,03

MX15 68.8 1,74 30.0 0,75 2961 1343 550 250 2063 1,33 245 11,73 0,119 968 439 1936 878 4 10 10.2 65,8 94.9 654 6,67

MX19 68.8 1,74 30.0 0,75 3100 1406 500 227 2063 1,33 251 12,01 0,122 1050 476 2100 953 4 10 10.2 65,8 102.9 709 7,23

SL20 92.5 2,35 33.0 0,84 3100 1406 750 340 3053 1,97 181 8,66 0,088 1150 522 2300 1044 4.5 11,4 13.1 84,5 87.7 605 6,17

X20N 92.5 2,35 32.5 0,82 3828 1736 750 340 3006 1,94 219 10,48 0,106 1400 635 2800 1270 4.5 11,4 11.8 76,1 118.6 818 8,34

X20W 92.5 2,35 48.0 1,22 4273 1938 1000 454 4440 2,86 149 7,13 0,072 1600 726 3200 1452 4.5 11,4 15.6 101 102.6 707 7,21

X26N 92.5 2,35 48.0 1,22 4747 2153 1000 454 4440 2,86 171 8,19 0,083 1750 794 3500 1588 4.5 11,4 16.1 104 108.7 749 7,64

X26UN 92.5 2,35 32.5 0,82 5200 2358 500 227 3006 1,94 273 13,07 1,133 1750 794 3500 1588 4.5 11,4 16.1 104 108.7 749 7,64

X31N 92.5 2,35 48.0 1,22 5480 2485 700 317 4440 2,86 200 9,58 0,097 1850 839 3700 1678 4.5 11,4 16.3 105 113.5 783 7,98

X32N 92.5 2,35 48.0 1,22 5480 2485 700 317 4440 2,86 200 9,58 0,097 1850 839 3700 1678 4.5 11,4 16.3 105 113.5 783 7,98

Loading...

Loading...