36

… 7 Installation

Pneumatic connections

Note

The positioner must only be supplied with instrument air that is

free of oil, water, and dust (in gas configuration with dried

natural gas).

The purity and oil content must meet the requirements of Class

3 according to DIN/ISO 8573-1.

NOTICE

Damage to components!

Contamination on the air pipe and positioner can damage

components.

• Dust, splinters, and any other particles of dirt must be

blown-out before the pipe is connected.

NOTICE

Damage to components!

Pressure above 10 bar (145 psi) can damage the positioner

or actuator.

• Provisions must be made, e.g. by using a pressure

reducer, to make sure that the pressure does not rise

above 10 bar (145 psi), even in the event of a fault.

Information on double acting actuators with spring-

return mechanism

On double-acting actuators with spring-return mechanism, a

pressure that significantly exceeds the supply air pressure value

can be generated during operation by the springs in the

chamber opposite the springs.

This may damage the positioner or adversely affect control of

the actuator.

To eliminate the possibility of this occurring, it is recommended

to install a pressure compensation valve between the springless

chamber and the supply air for these types of applications. It

enables the increased pressure to be transferred back to the air

inlet line.

The opening pressure of the check valve should be < 250 mbar

(< 3.6 psi).

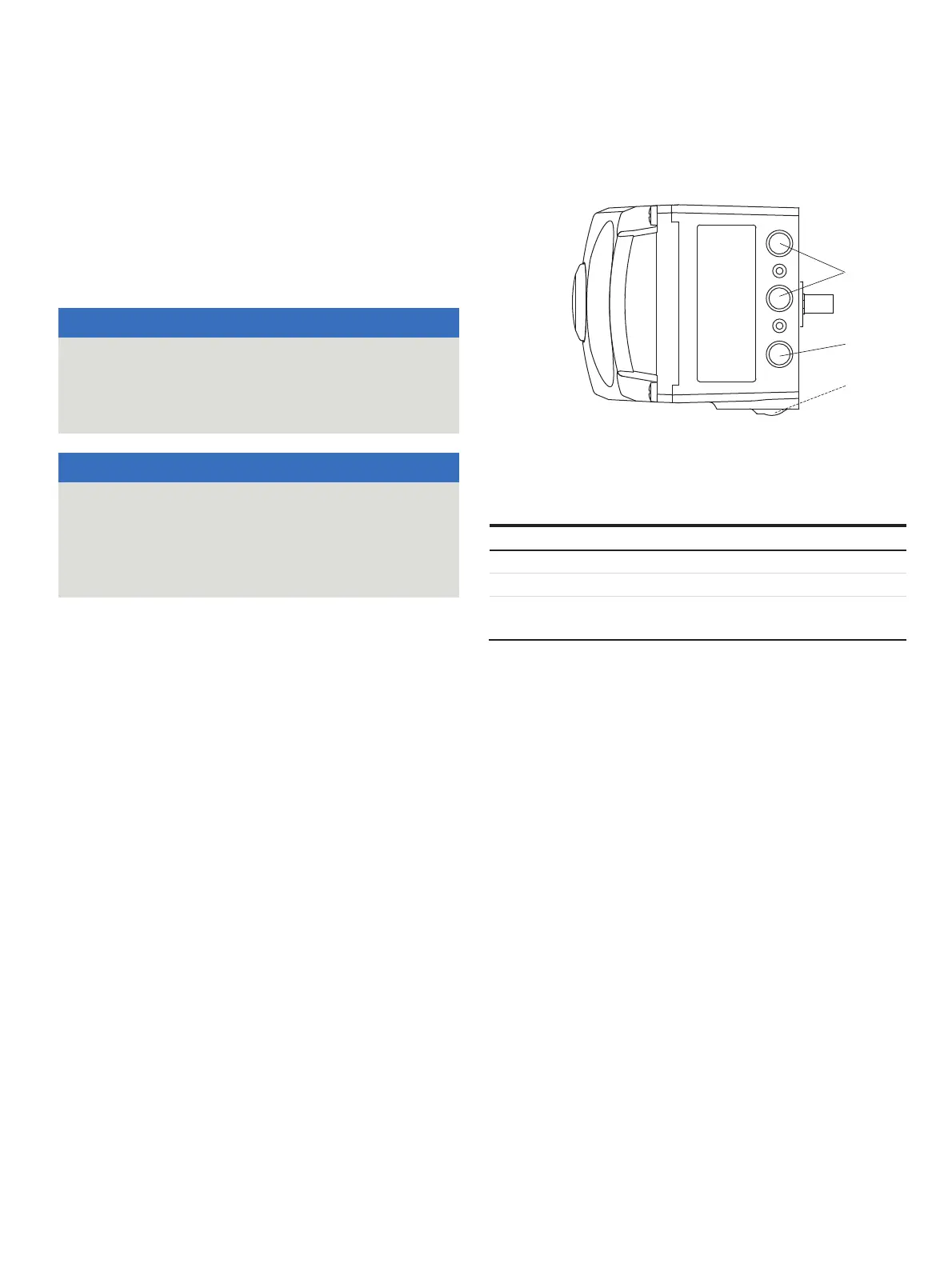

Connection on the device

M10132-01

2

3

NPT1/4"

G1/4"

Y2

2OUT

Y1

1OUT

SUP ZUL/

IN

1

1 Pneumatic outputs

2 Supply air

3 Filter screw (on underside of

housing)

Figure 27: Pneumatic connections

Marking Pipe connection

SUP / ZUL IN Supply air, pressure 1.4 to 10 bar (20 to 145 psi)

Y1 / OUT1 Output pressure to the actuator

Y2 / OUT2 Output pressure to the actuator

(2 Connection with double acting actuator)

Join the pipe

connections according to the designation,

observing the following points:

•

All pneumatic piping connections are

located on the

right-hand side of the positioner. G¼ or ¼ 1

8

NPT tap

holes

are provided for the pneumatic connections. The

positioner is labeled according to the tap holes available.

•

We recommend that you use a pipe with di

mensions of

12 × 1.75 mm. The supp

ly air pressure req

uired to apply

the act

uating force must be adjusted in line

with the

output pressure in the

actuat

or.

•

The operating range of the

positioner is between

1.

4 to 10 bar (20 to 145 psi).

Loading...

Loading...