28

… 7 Installation

… Electrical connections

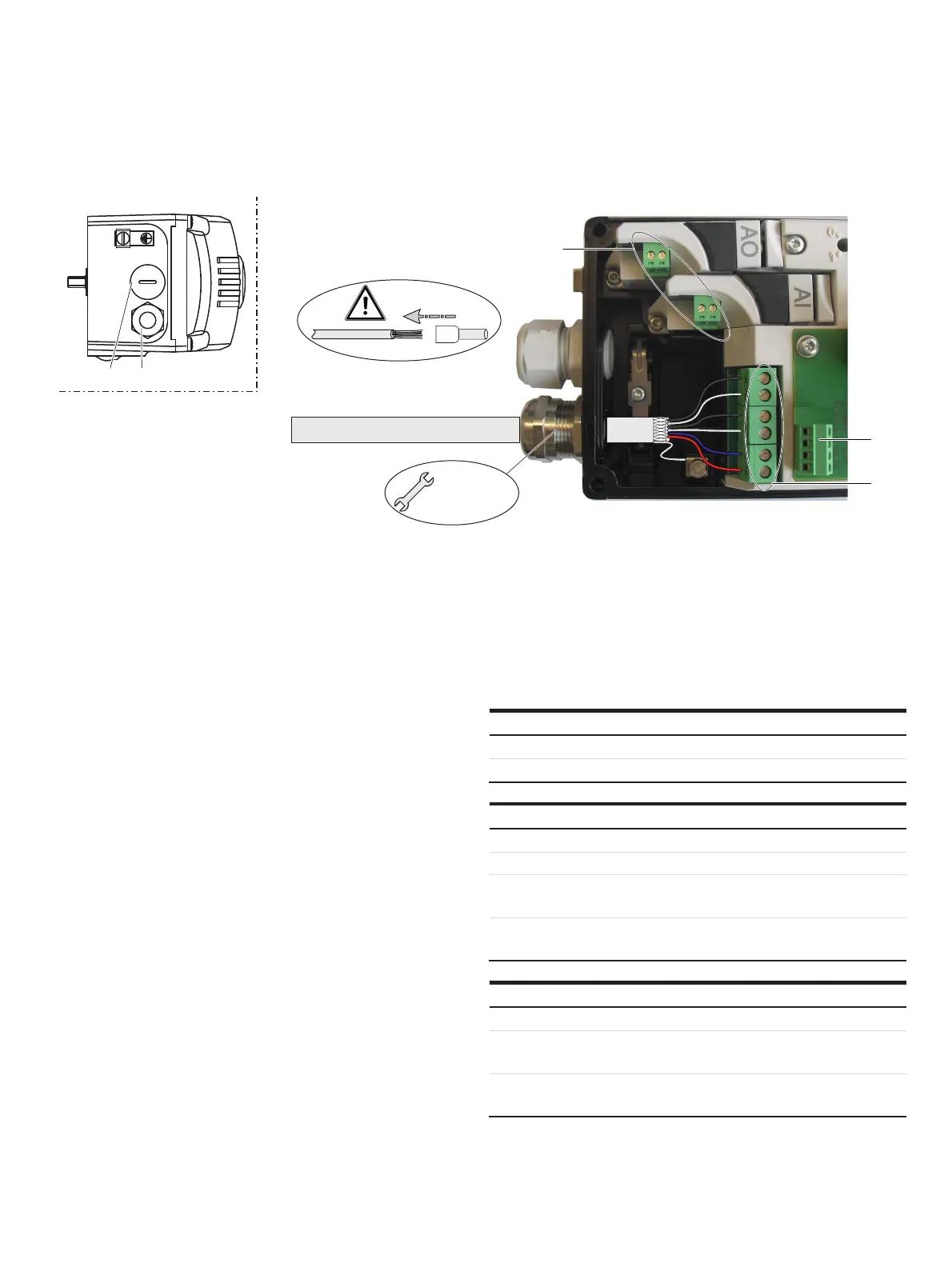

Connection on the device

M10950

M 20 mm /

1/2"NPT

1 2

3

4

5

1 Blind plug

2 Cable gland

3 Terminals for options modules

4 Terminals attachment set for digital feedback

5 Terminals basic device

Figure 22: Connection on device (example)

Change from one to tw o columns

2 tap holes ½- 14 NPT or M20 × 1.5 are provided on the left side

of the housing for cable entry in the housing. One of the tap

holes is fitted with a cable gland, while the other tap hole has a

blind plug.

Note

The connecting

terminals are delivered closed and must be

unscrewed before inserting the wire.

1. Strip the wires to approximately 6 mm (0.24

in).

2. Connect the wi

res to the connect

ing terminals in line with

the connection diagram.

Wire cross-sectional areas

Basic device

Electrical connections

4 to 20 mA input Screw terminals max. 2.5 mm

2

(AWG14)

Options Screw terminals max. 1.0 mm

2

(AWG18)

Cross section

Rigid / flexible wires 0.14 to 2.5 mm

2

(AWG26 to AWG14)

Flexible with wire end sleeve 0.25 to 2.5 mm

2

(AWG23 to AWG14)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 1.5 mm

2

(AWG23 to AWG17)

Flexible with wire end sleeve

with plastic sleeve

0.14 to 0.75 mm

2

(AWG26 to AWG20)

Multi-wire connection capacity (two wire with the same cross-section)

Rigid / flexible wires 0.14 to 0.75 mm

2

(AWG26 to AWG20)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 0.75 mm

2

(AWG23 to AWG20)

Flexible with wire end sleeve

with plastic sleeve

0.5 to 1.5 mm

2

(AWG21 to AWG17)

Loading...

Loading...