16 Instructions for installation and servicing ecoTEC 839592_12

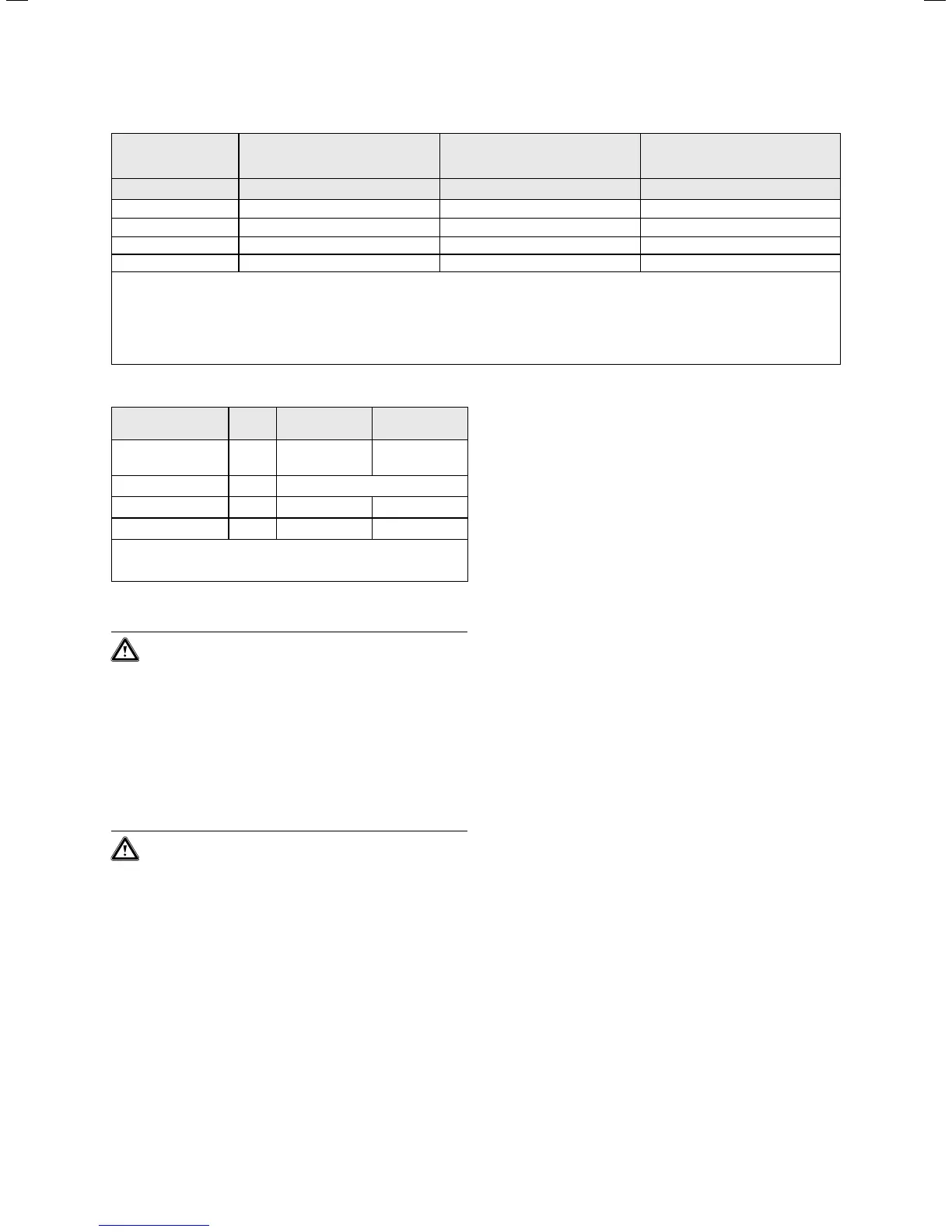

Total heating

output

Total hardness at 20 l/kW

for the smallest boiler heating

surface

2)

Total hardness at > 20 l/kW

< 50 l/kW for the smallest boiler

heating surface

2)

Total hardness at > 50 l/kW

for the smallest boiler heating

surface

2)

kW mol/m

3

mol/m3 mol/m

3

< 50 No requirement or < 3

1)

2 0,02

> 50 to ≤ 200

2 1,5 0,02

> 200 to ≤ 600

1,5 0,02 0,02

> 600

0,02 0,02 0,02

1) with systems equipped with wall-hung boiler and systems with electric heating elements

2) of the specific system volume (nominal capacity in litres/heating output; in case of multiple boiler systems the lowest individual

heating output should be used)

These data only apply up to 3x the system volume for filling and top-up water. Once this triple system volume is exceeded, the

water will have to be treated exactly the same as in case of exceeding the limit values given in Table 3.6 (softening, desalination,

hardness stabilisation and desludging).

Table 3.5 Guidelines for the heating water: Water hardness

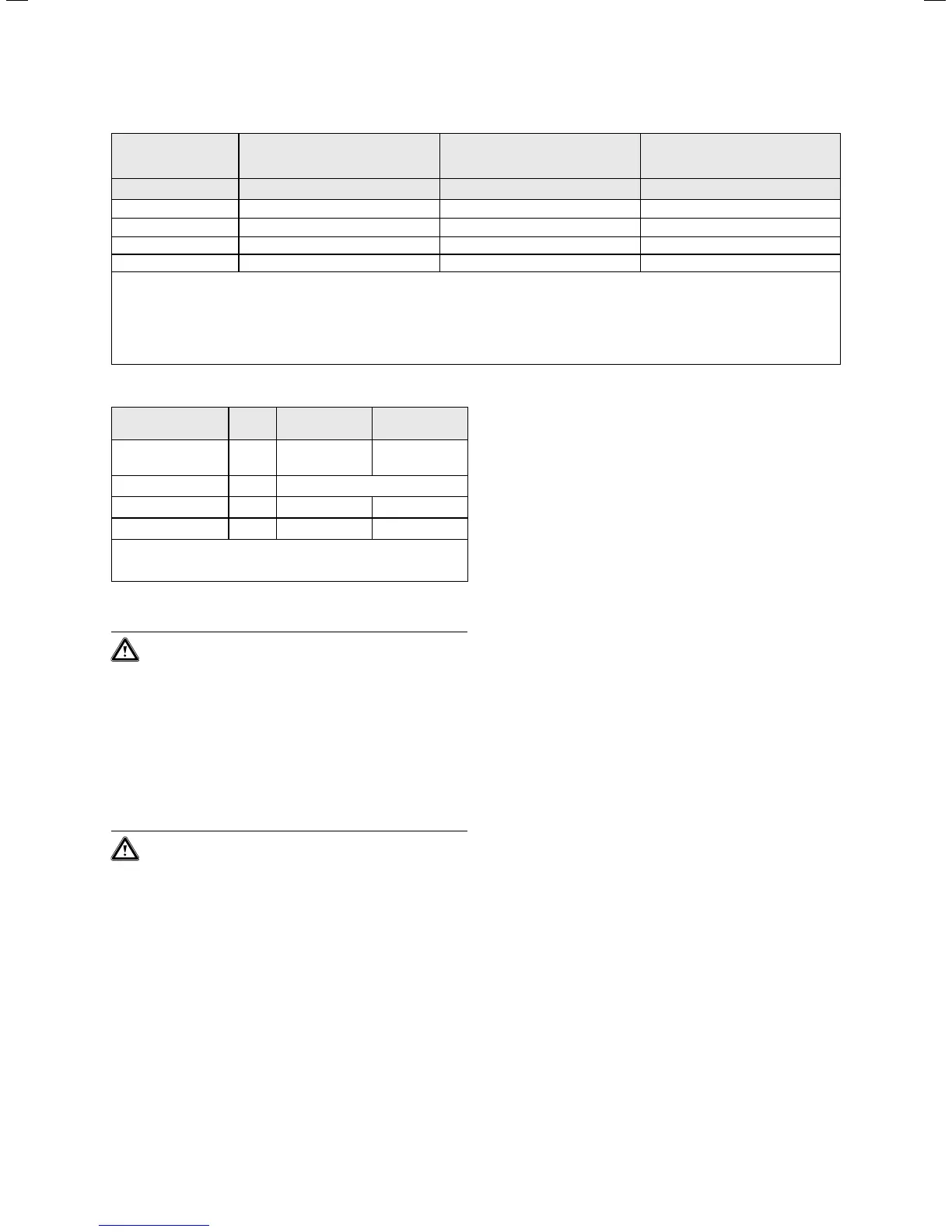

Heating water

qualities

Unit Low-salt saline

Electric conductivity

at 25 °C

µS/cm < 100

100-1500

Appearance Free of sedimentary substances

pH-value at 25 °C 8,2-10,0

1)

8,2-10,0

1)

Oxygen mg/L

< 0,1 < 0,02

1) With aluminium and aluminium alloys, the ph value range is

restricted from 6.5 to 8.5.

Table 3.6 Guidelines for heating water: Salinity

Caution!

Aluminium corrosion resulting in leakages

caused by unsuitable heating water!

Unlike materials such as steel, cast iron or cop-

per, aluminium is reactive to alkalised heating

water (pH-value > 8,5) which results in signifi-

cant corrosion.

With aluminium, ensure that the pH value of

the heating water ranges between 6.5 up to a

maximum of 8.5.

Caution!

Risk of material damage if the heating water is

treated with unsuitable frost or corrosion pro-

tection agents!

Frost and corrosion protection agents may

cause changes in the seals, noises during heat-

ing and possibly subsequent damage.

Do not use any unsuitable frost or corrosion

protection agents.

3.10.3 Pressure relief valve

A pressure relief valve is provided with the boiler. This

safety device is required on all sealed C.H. systems and

is preset at 3 bar and provided with a 15 mm

compression connection for a discharge pipe, which

must be of no less than 15 mm in diameter. The pressure

relief valve must not be used for draining purposes.

3.10.4 Pressure gauge

This is factory fitted to the boiler and indicates the

primary circuit pressure to facilitate filling and testing.

3.10.5 Expansion vessel

ecoTEC boilers incorporate a 10 litre expansion vessel

which is suitable for a sealed heating system with a

maximum water content of 100 litres.

If the nominal capacity of the built in expansion vessel is

not sufficient for the heating system (for instance in

case of modernisation of old open systems) an

additional expansion vessel can be installed external to

the boiler. It should be fitted in the return pipe as close

as possible to the boiler in accordance with BS 5449:

Part 1.

Guidance on the sizing of an additional expansion vessel

is given in Table 3.7.

3 General requirements

Loading...

Loading...