43Instructions for installation and servicing ecoTEC 839592_12

Note

The boiler is fitted with a flue gas analysis

point (4). A suitable flue gas analyser can be

connected to this point to establish the

combustion performance of the boiler.

• Remove the front casing.

• Start the testing program P.1.

• Wait at least 5 minutes until the boiler reaches its

operating temperature.

• Measure the CO

2

concentration at the flue gas

analysis point (4). Compare the measured value with

the corresponding value in Table 7.1.

• If all these points are as required, proceed as

described in section 7.1.5.

• If one of the flue gas values is greater than the

acceptable values in Table 7.1, then proceed as

described in the following section 7.1.4.

7.1.4 Adjusting the CO

2

concentration

(or the air ratio)

d

Danger!

Increased risk of poisoning due to incorrect

settings!

Incorrect setting may increase the risk of

poisoning.

• If one of the flue gas values is greater than

the acceptable values in Table 7.1 then check

- the integrity of the complete flue gas

installation

- the integrity of the combustion circuit seals

- the gas inlet working pressure

- the gas flow rate.

If the flue gas value needs to be adjusted,

• unfasten the screw (Fig. 7.1, 2) and

• fold the air intake pipe (Fig. 7.1, 3) forwards through

90°. Do not remove the air intake pipe.

• Specify the required flue gas value if necessary (value

with front casing of boiler removed, see Table 7.1) by

turning the screw of the main throttle (Fig. 7.1, 1).

h

Note

Use a 4 mm hexagon socket spanner to turn

the screw.

• Turn to the left: higher CO

2

concentration,

• Turn to the right: lower CO

2

concentration.

h

Note

Natural gas: Only perform the adjustment in

increments of 1/8 turn and wait approximately

1 minute after each adjustment until the value

stabilises.

Liquid gas: Only perform the adjustment in very

small increments (approximately 1/16 turns),

and wait approximately 1 minute after each

adjustment until the value stabilises.

• After performing the adjustments, fold the air intake

pipe back up.

• Check the CO

2

concentration once again.

• If necessary, repeat the setting process.

• Push the „i“ button to deactivate the full load mode.

The full load mode is also deactivated if no button is

pushed for 15 minutes.

• The adjusting screw shall be sealed after the

adjustment.

• Re-secure the air intake pipe with the screw (2).

• Put the front casing back on.

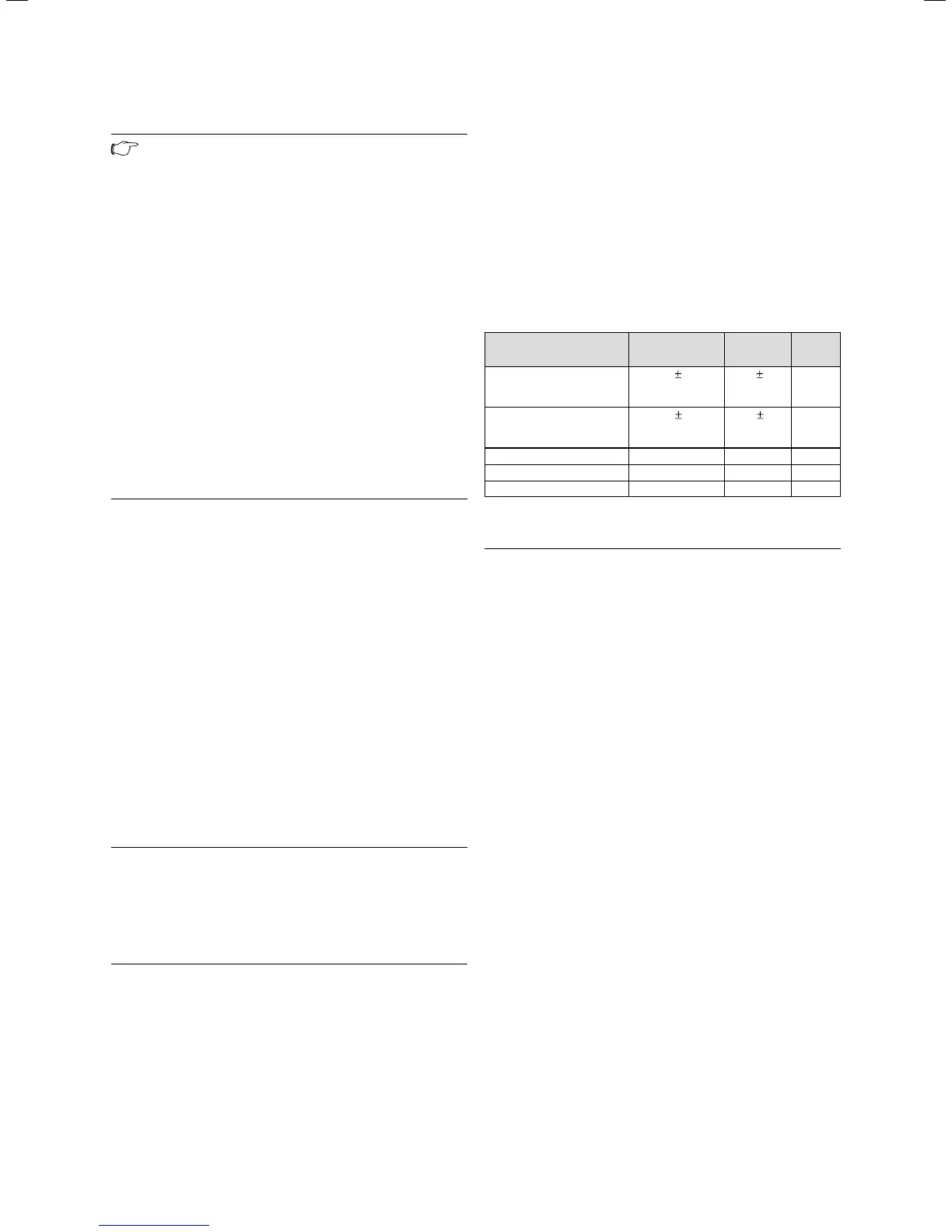

Settings Natural gas (H)

Tolerance

Propane

Tolerance

Unit

CO

2

after 5 min. full load

mode with appliance

front closed

9.2 1,0 10.2 0,5 Vol.–%

CO

2

after 5 min. full load

mode with appliance

front removed

9.0 1,0 10.0 0,5 Vol.–%

Set for Wobbe-Index W

0

15 22.5 kWh/m

3

CO value with full load < 250 < 250 ppm

CO/CO

2

< 0,0031 < 0,0026

Table 7.1 Factory gas setting

d

Danger!

Risk to life due to poisoning!

CO is an extremely toxic gas. Risk to life due to

excessive CO concentrations.

• If you are not able to adjust the boiler

correctly and the flue gas values remain

higher than allowed in Table 7.1, call the

Vaillant Service Solutions.

• Do not start up the boiler!

Inspection and maintenance 7

Loading...

Loading...