Dedicated Outdoor Air Unit30

Sequence of Operation

Optional Economizer - The economizer will be locked

out when: the outside air is below economizer lockout;

the unit is operating in dehumidification mode; or there

is a call for heating.

• Stop Wheel: When economizer mode is enabled

and there is a signal for cooling, the wheel will stop

rotating to allow free cooling.

• Modulate Wheel: When economizer mode is

enabled and there is a signal for cooling, the

wheel VFD modulates wheel speed to maintain the

discharge temperature set point.

Optional Frost Control - The microprocessor controller

will output a signal when wheel frosting is occurring

which is determined by a temperature set point (OA

<5°F – 2°F hysteresis, adjustable) and wheel pressure

drop increase.

• Preheat: When frosting is occurring, the preheater

is energized to defrost the wheel. Once the

pressure drop decreases below the set point, the

preheater is de-energized.

• Modulating Wheel: Includes a VFD in addition

to the thermostat and pressure sensor. When

modulating wheel frost control is initiated, the VFD

will reduce the speed of the wheel, which keeps

the exhaust air condition from reaching saturation,

thus, eliminating condensation and frosting. If the

outdoor air temperature is greater than the frost

threshold temperature OR the pressure differential

is less than the set point, the wheel will run at

full speed. If the outdoor air temperature is less

than the frost threshold temperature AND the

pressure differential is greater than the set point,

the wheel will run at reduced speed until the

pressure differential falls below the set point. The

temperature and pressure differential set points are

set at the factory, but are field-adjustable. The VFD

will be fully programmed at the factory.

Optional Energy Wheel

Start-Up

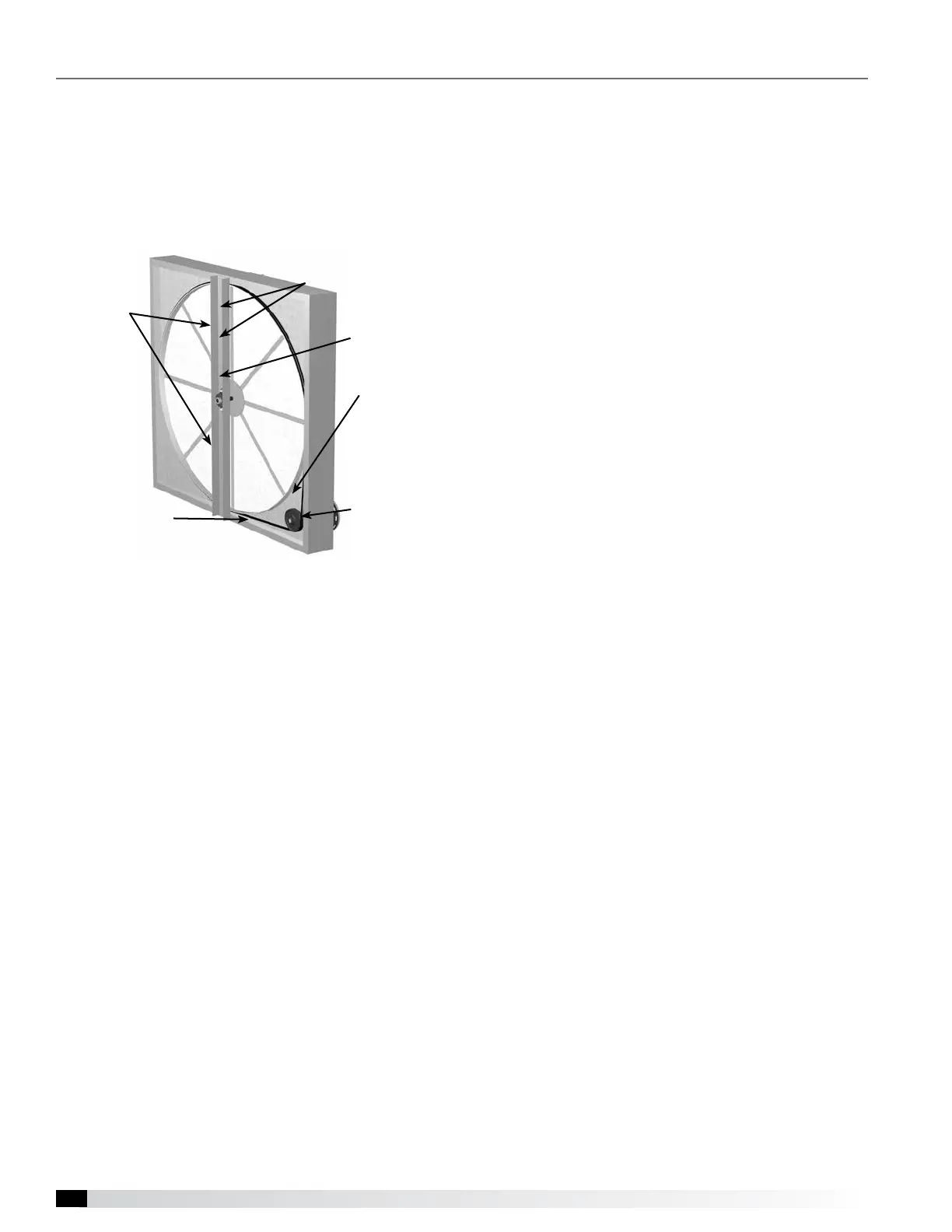

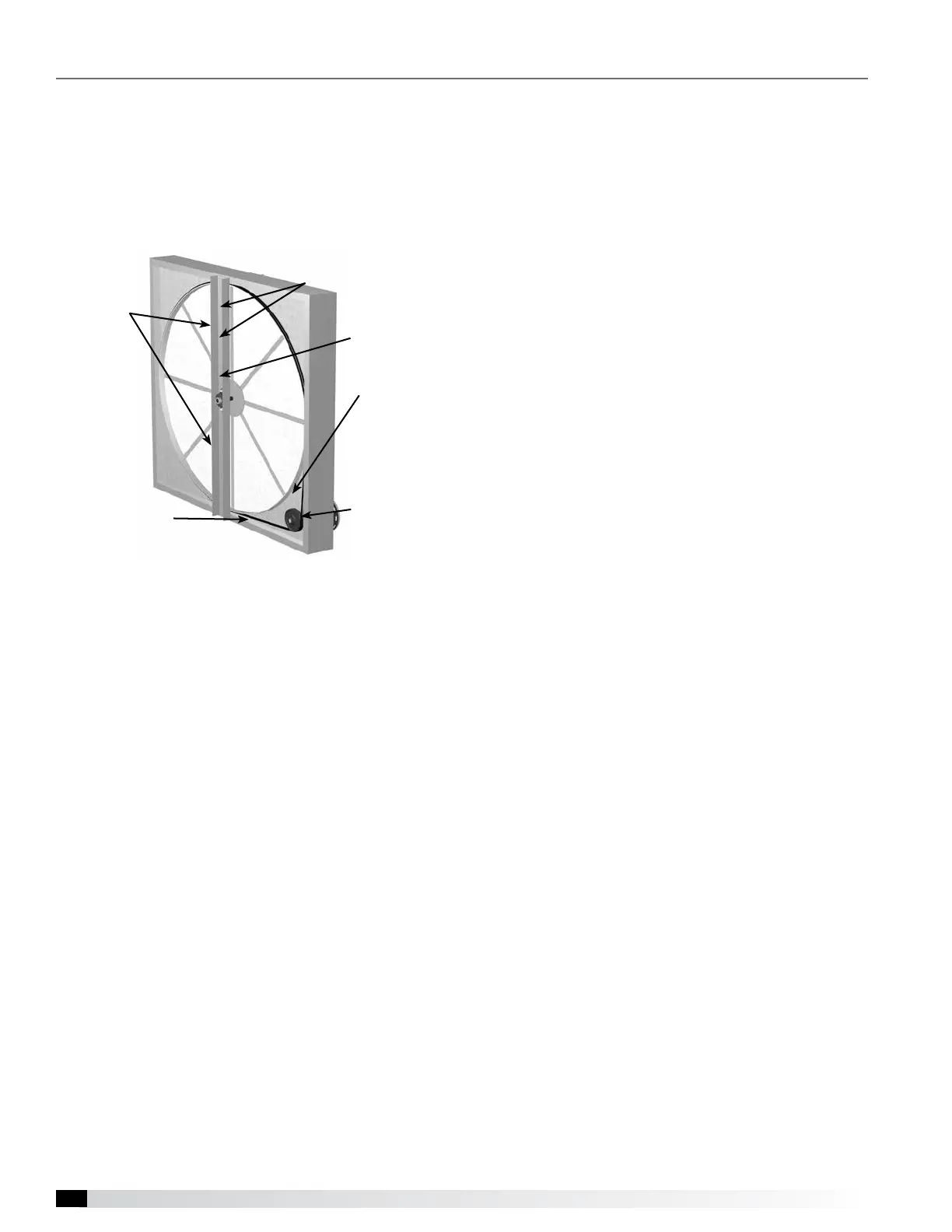

If selected, the energy wheel is installed in the unit’s

airstream with one half of the wheel in the intake

airstream and one half in the exhaust airstream. Air

leakage between the two airstreams has to be kept to

a minimum and the wheel has air seals that must be

adjusted for that purpose. The seals must be adjusted

at time of start-up.

Drive Belt

Inspect the drive belt. Make sure the belt rides smoothly

in the pulley and around the outside of the wheel. Note

the directional arrow and data information shown in the

image.

Adjust the Air Seals

Make sure the unit power supply is locked out.

Disconnect the wiring to the wheel module and pull

the wheel cassette out of the cabinet on its tracks.

Large cassettes are not removable. Then slowly rotate

the wheel by hand to make sure there is no binding or

misalignment.

There is a perimeter seal located around the outside of

the wheel and a diameter seal across the face of the

wheel on both sides. Check to make sure that all air

seals are secure and in good condition.

Adjust the air seals by loosening all the air seal retaining

screws on the bearing support. Using a piece of paper

as a feeler gauge, adjust the seals so they almost touch

the face of the wheel while tugging slightly on the paper.

When the wheel is rotated, there should be a slight tug

on the paper. Tighten the screws, repeat the steps on

the other set of seals.

Push the wheel cassette back into the unit and plug

in the power connector. Turn the main power supply

back on and then observe the operation of the wheel by

opening the wheel access door slightly. Remove filters if

necessary to observe the wheel.

Drive Belt

Adjustable

Air Seals

Label

showing

cassette

serial # and

date code

Bearing

Support

Drive Pulley

Retaining

Screws

Loading...

Loading...