Dedicated Outdoor Air Unit32

Optional Energy Wheel – Troubleshooting

Symptom Possible Cause Corrective Action

Energy wheel

does NOT

turn

Air seals are too tight.

Refer to Adjust the Air Seals in the Optional Energy Wheel

Start-Up section.

Broken belt. Replace.

No power to wheel motor. Make sure wheel drive is plugged in. Verify power is available.

Energy

wheel runs

intermittently

Wheel motor overloads are

tripping due to rubbing between

wheel and air seals.

Recheck air seals, make sure they are not too tight. See Adjust

the Air Seals in the Optional Energy Wheel Start-Up section.

Troubleshooting – Alarms

Several of the electronic controls in the unit monitor the

system for faults and will go into alarm, shutting down

the unit or a single function within the unit.

Microprocessor Controller

The microprocessor is located in the main control

center. If the microprocessor is in alarm condition,

the Alarm button will blink red. Press the Alarm

button to see the specific condition or to reset the

microprocessor. Refer to the microprocessor IOM for

detailed information on fault codes and see the unit-

specific wiring diagram.

Phase Monitor

The phase monitor has two LED indicator lights, one

red and one green. Green indicates proper operational

status, red indicates the unit has detected a fault and is

in alarm condition. The alarm LED will blink to show the

specific fault and there is a chart printed on the monitor

that shows the code for the blinking light. The phase

monitor is self-resetting once the alarm condition is

corrected. It is located in the main control center.

Variable Frequency Drive (VFD)

Variable frequency drives have a display screen that will

show an alarm condition. If a fault such as a voltage

spike occurs, the VFD will go into alarm and will not

reset until a hard restart is performed. See the unit-

specific manufacturer’s manual supplied with the unit.

VFDs are located in the main control center.

Optional Digital Scroll Compressor

Controller

Present only if packaged DX with digital scroll option is

selected. The controller has

three LED indicator lights.

One is green, indicating that

it has power, one is an alarm

indicator that will flash a code

for various alarm conditions

and the third indicates

whether the compressor

is operating in a loaded or unloaded condition. See

the manufacturer’s unit-specific manual for further

information.

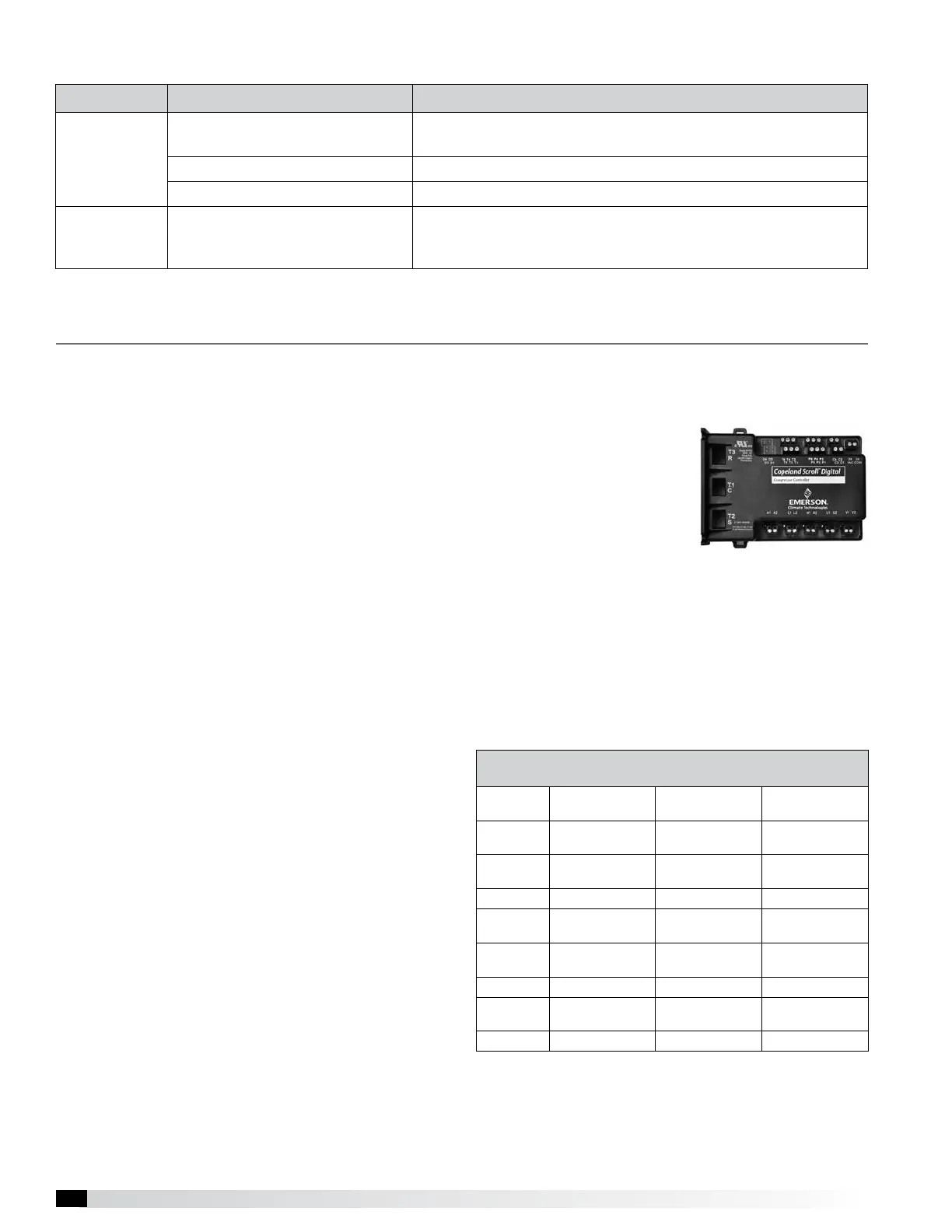

See the Fault Code chart below. The Fault Code chart

is also printed on the back of the controller. Note that

if the controller generates either a Code 2 or a Code 4

Lockout, a manual reset must be performed. Manual

Reset is accomplished by shutting off main power to the

unit and then turning it back on.

Digital Scroll Compressor

Controller Fault Codes

Alert Code

System

Condition

Diagnostic

Alert Light

Action

Code 2*

High Discharge

Temperature Trip

Blinks 2 Times Lockout

Code 3

Compressor

Protector Trip

Blinks 3 Times Lockout

Code 4* Locked Rotor Blinks 4 Times Lockout

Code 5

Demand Signal

Loss

Blinks 5 Times Lockout

Code 6

Discharge

Thermistor Fault

Blinks 6 Times

Reduce

Capacity

Code 7 Future N/A N/A

Code 8

Welded

Contactor

Blinks 8 Times

Unload

Compressor

Code 9 Low Voltage Blinks 9 Times Trip Compressor

*Protective faults that require manual reset.

Loading...

Loading...