function. If it is not possible to achieve sufficient brake performance by fully screwing screw () in, screw in the brake adjusting bolt (

in

D: >

) on the handlebars, so that the bowden axle clearance in the adjusting bolt is 1 mm, and then check the automatic brake

function

t

.

"%B(&(&$$,%$$ 9$*%,9

$:)F&DFB%D(&r

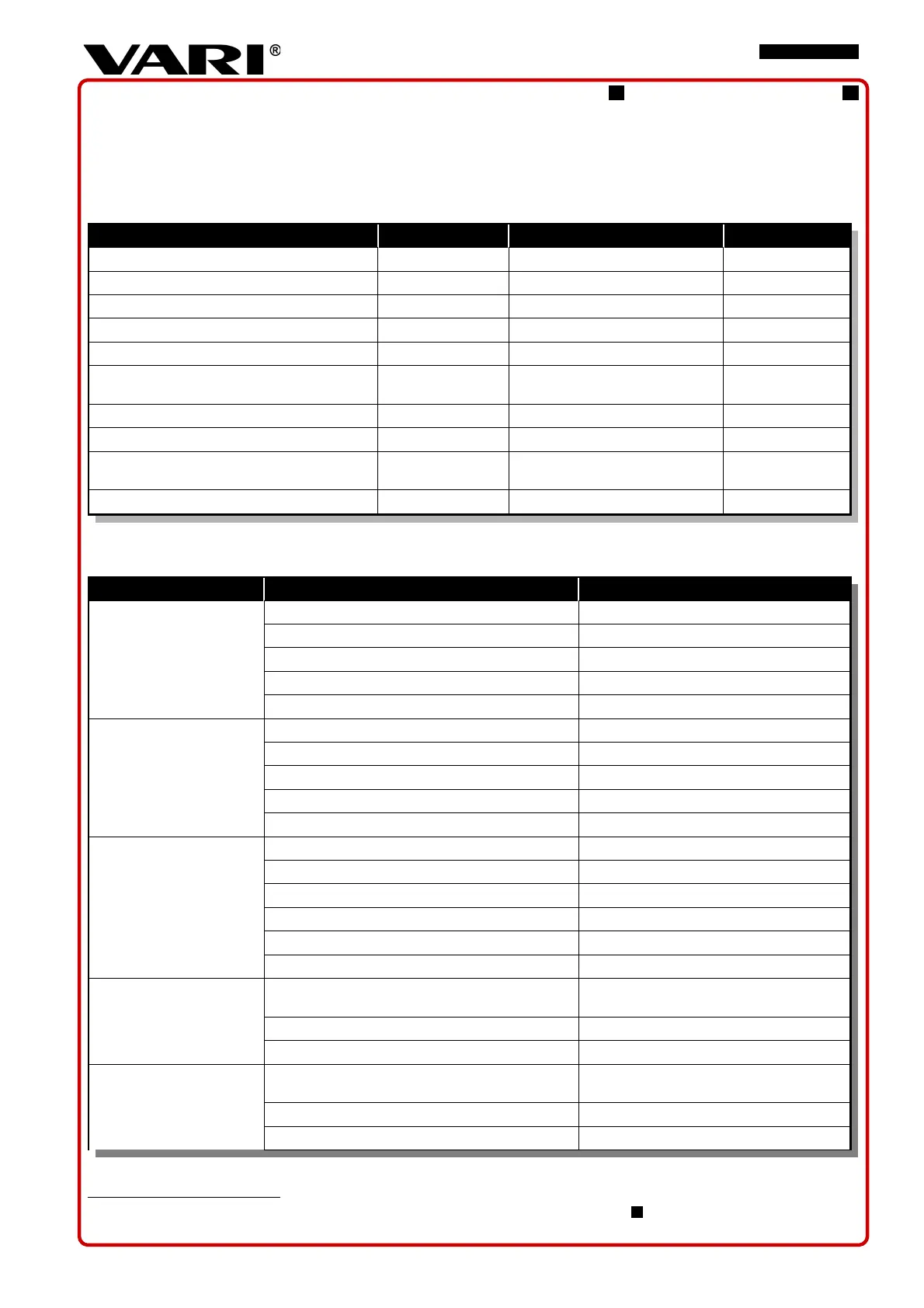

2.5.5 SERVICING INTERVALS

l, B 7DB D

Checking engine oil level Yes per the engine operating instructions Yes

Engine air filter cleaning Check every 10 hours

t

Yes

Washing - 2x Yes

Removing dirt and mowed growth debris - After every mowing Yes

Working tool cutting edge sharpening Check As needed Yes

Blade mount inspection Yes Immediate replacement upon

damage

Yes

Working tool (blade) tightening inspection Yes - Yes

Checking tightening of screwed connections Yes Every 5 hours Yes

Lubrication Check of the

condition

+(>@

Yes

V-belts check - Every 20 hours Yes

+(?!D

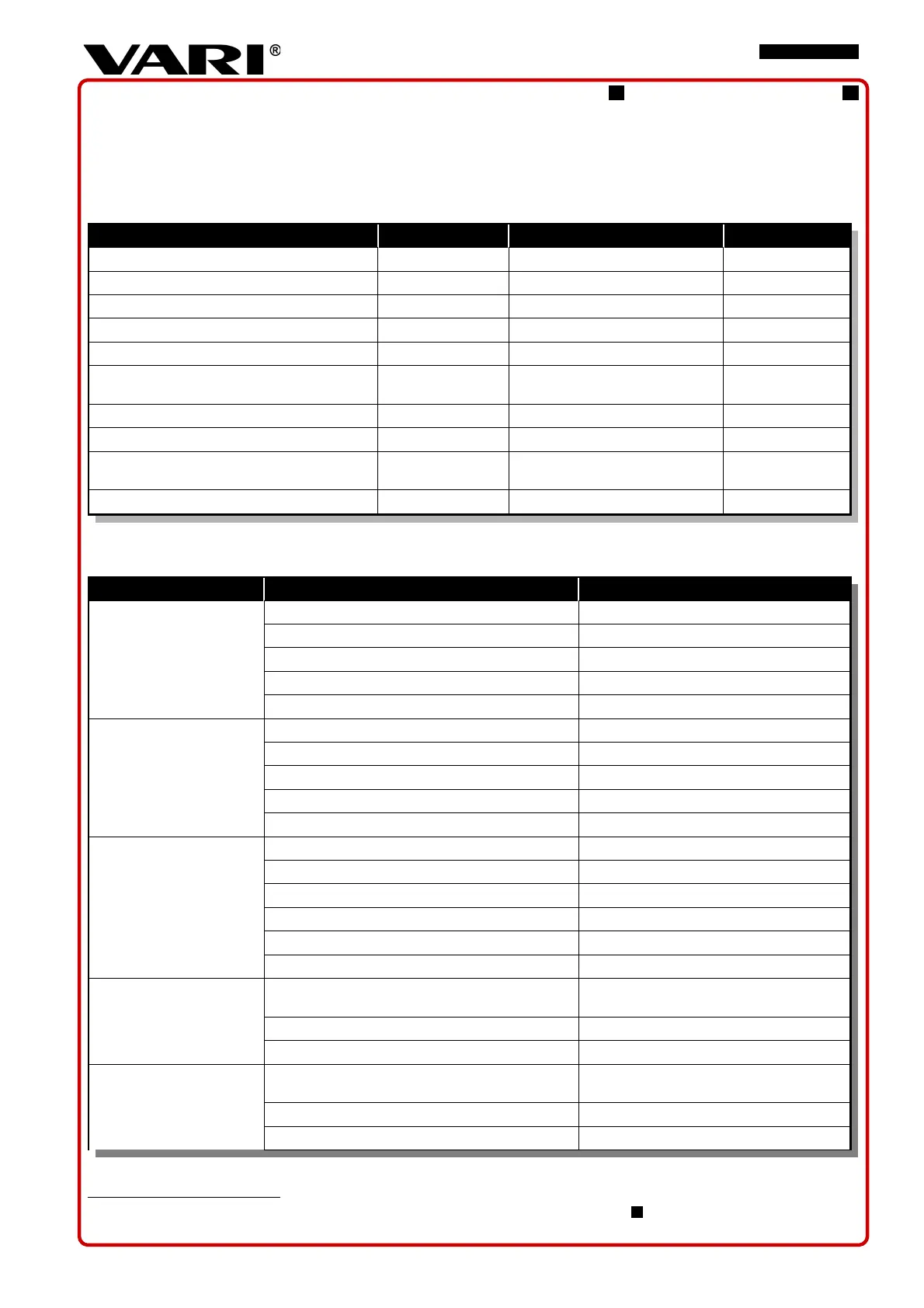

2.5.6 TROUBLESHOOTING

(

The work tool will not rotate The disk drive clutch lever is not pressed Press the lever

Insufficient belt tension Adjust the tension pulley

Torn belt Replace the belt

The belt has come off Re-mount the belt

Other defect Visit a service facility

The machine is not moving The travel clutch lever is not pressed Press the lever

Insufficient belt tension Adjust both the tension pulleys

Torn belt Replace the belt

The belt has come off Re-mount the belt

Other defect Visit a service facility

The engine will not start The petrol tank is empty Add petrol

The petrol supply line is closed Open the petrol supply line

Other defect Visit a service facility

The battery is not sufficiently charged Charge the battery

Disconnected starter panel cable connector Connect the connectors

Defective switch or cable harness Replace with new ones / visit a service centre

The brake does not brake There is no axial clearance in the bowden cable, the

cable is stretched

Adjust the brake

The brake key is not loose Do not lubricate the key mount

Brake lining is worn - brake cannot be adjusted Visit a service facility

The machine travel will not

stop

The tension pulley does not return back to its position Lubricate

The inner bowden cable is stiff; bent bowden cable Lubricate or replace the bowden cable

Broken travel pulley spring Replace with a new one

89

It is possible to proceed in the opposite way as well – first, screw in (towards the handlebars crossbar) the brake bowden bolt

in D:> on the handlebars, so you achieve the

axial clearance of 1 mm in the adjusting bolt.

90

In the event of a very dusty environment, the check and cleaning should be done every hour!

@A

Revize 10/2019

Loading...

Loading...