1

2

3

4 5

6

7

88

53

54

Minimum

Current

Press & hold

Trigger

Release

Trigger

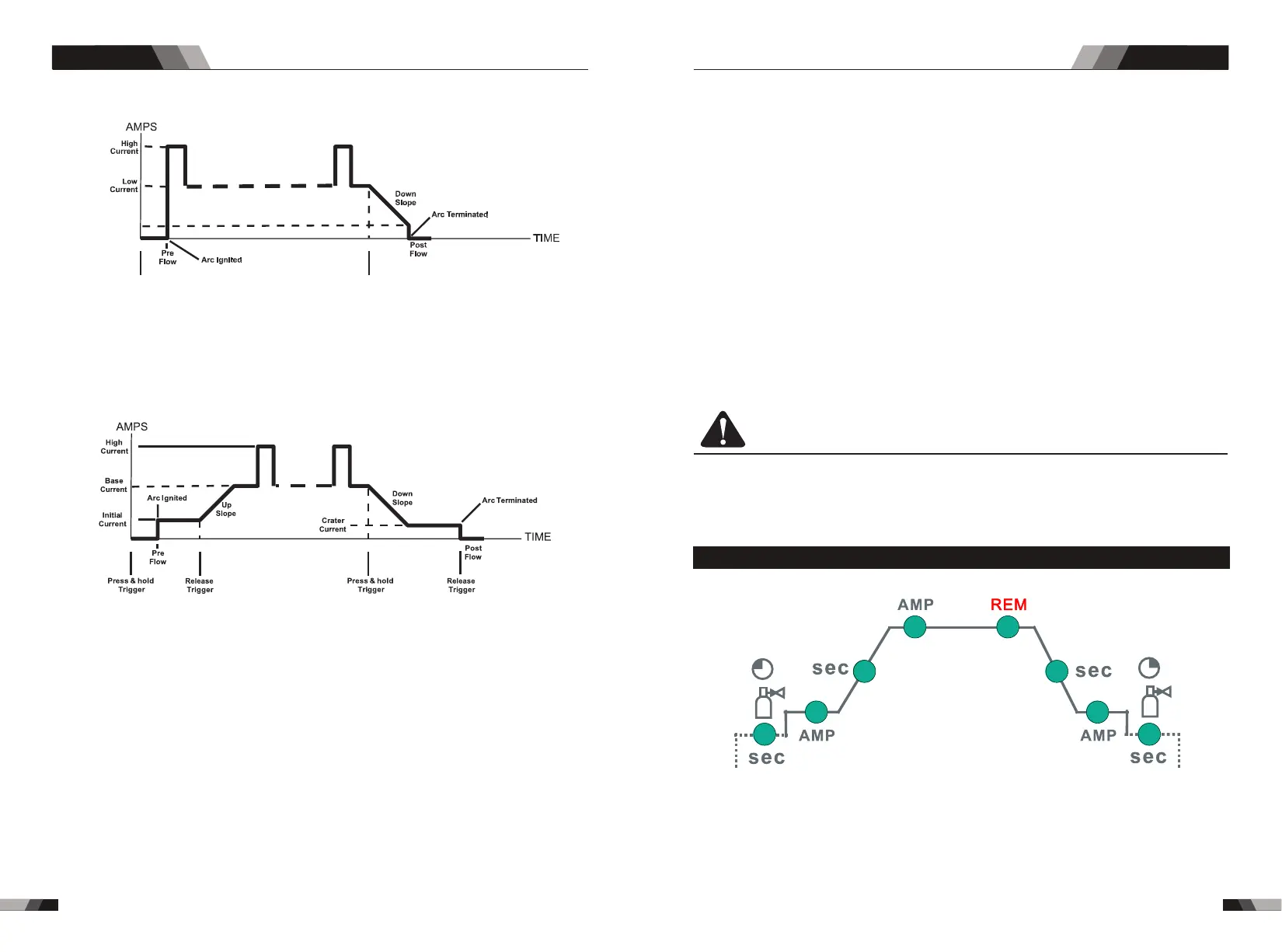

Note: that when operating in GTAW (HF and LIFT TIG modes), the power source will

remain activated until the selected down slope time has elapsed

4T Latch mode this mode of welding is mainly used for long welding runs to reduce operator

fatigue. In this mode the operator can press and release the torch trigger and the output will

remain active. To deactivate the power source, the trigger switch must again be pressed

and released, thus eliminating the need for the operator to hold the torch trigger.

Operation

Operation

Press and hold the torch trigger to activate the power source (weld). Release the torch trigger

switch to cease welding.

8. Prozess Knopf (WIG 200D No cutting function)

Die Prozess-Wahltaste dient zur Auswahl des gewünschten Schweißmodus. Es stehen

drei Modi zur Auswahl: GTAW (TIG), Manuelles Schweißen mit Stabelektrode (STICK)

und Schneiden (CUT).

9. Programming Parameter Indicators

These indicator lights will illuminate when programming.

10. Current adjusting button/functions choosing

Clockwise rotate to enlarge the current, and anti-clockwise rotate to reduce the current.

If you need to choose different programming parameters (the eighth mark), press the

button and release it to choose different functions.

11. Positive Welding Terminal

Positive Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

Note: CT 520PD positive pole press icon Connect the ground clip to the corresponding

function.

12. Negative Welding Terminal

Negative Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

13. 5 Pin Control Socket

The 5 pin receptacle is used to connect a trigger switch or remote control to the welding

Power Source circuitry:

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

14. Gas output interface

The gas output interface on the front panel is a fast connection of a suitable TIG torch.

15. Power switch

before using the machine. Pull the switch to the closure state of “AN” to operate the

machine, and pull the switch to “AUS” after use. Turn off the power input, and the machine

will stop operating.

16. Gas input interface

The gas port is connected with the gas valve output port. After connection, check whether

there is gas leakage.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug

being fused in the terminal.

3.2 Control panel

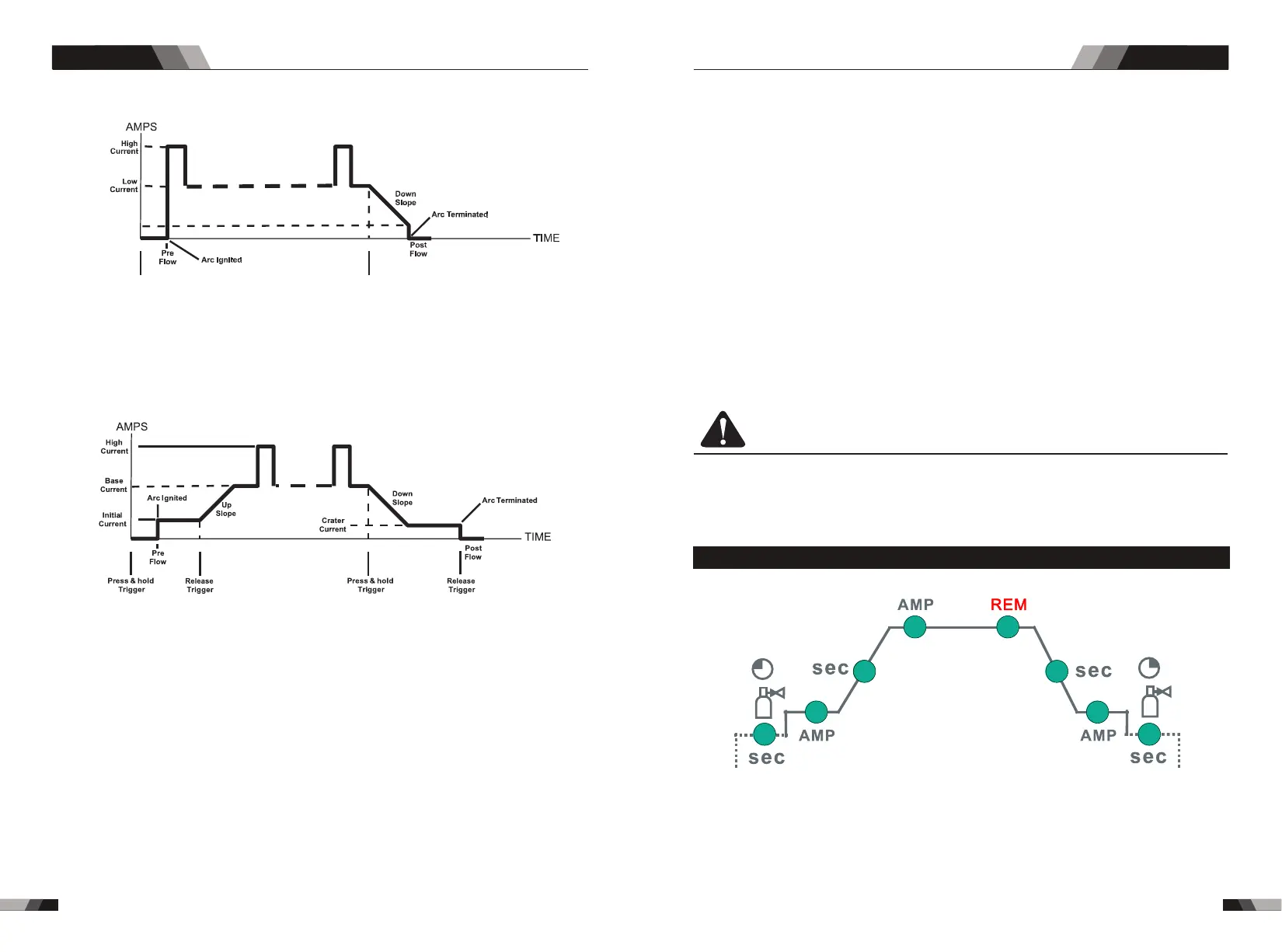

.Gas Pre-Flow 1

WIG 200D / CT 520PD: Absolute setting range 0.1s to 5s (0.1S increments)

This parameter operates in TIG modes only and is used to provide gas to the weld zone

prior to striking the arc, once the torch trigger switch has been pressed. This control is

used to dramatically reduce weld porosity at the start of a weld.

DC TIG SERIES EQUIPMENTDC TIG SERIES EQUIPMENT

Loading...

Loading...