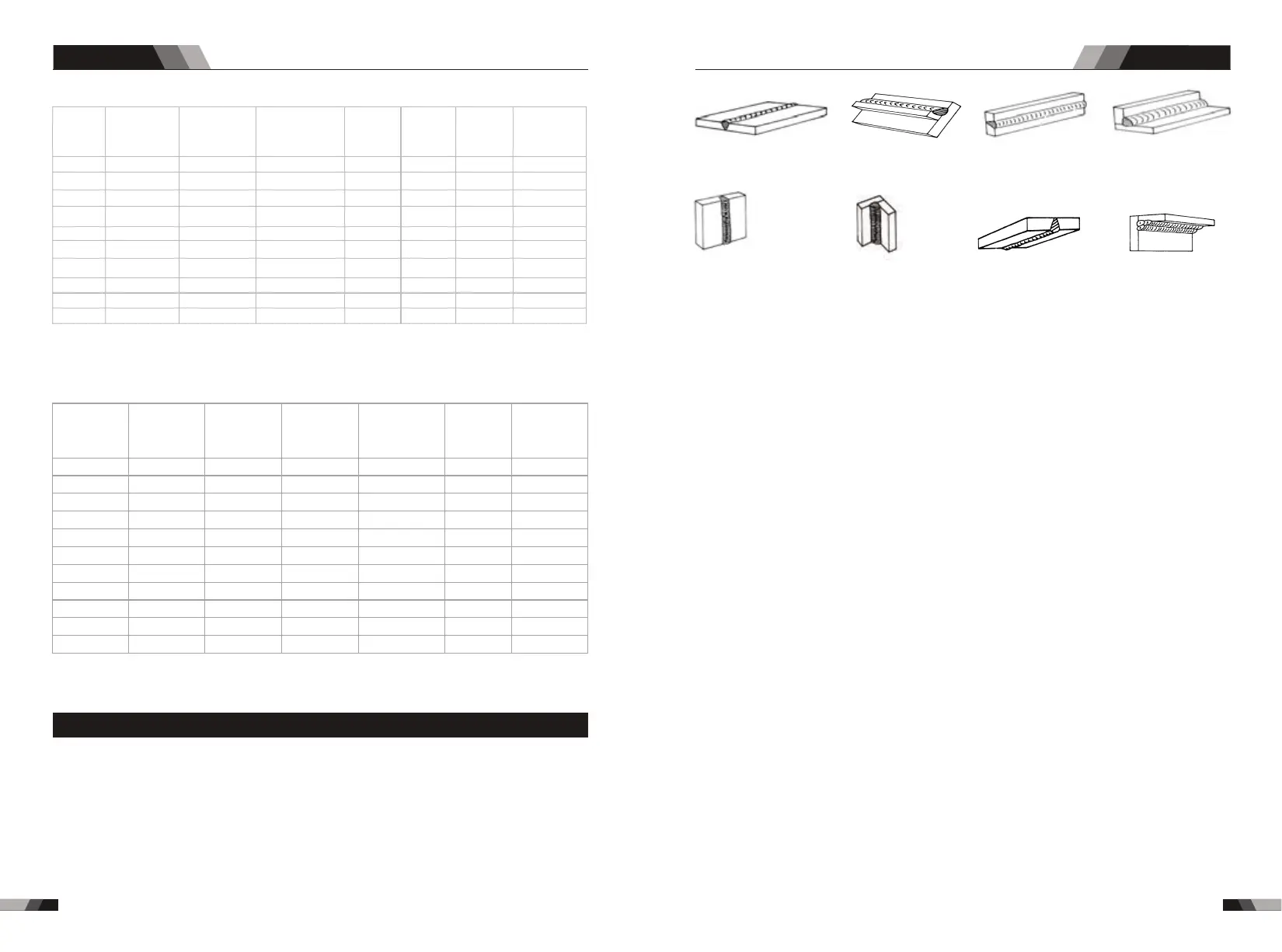

Parameters of piping back sealing welding for mild steel(DCEP)

Piping

diameter

Φ/mm

Tungsten

electrode

diameter/mm

Gas nozzle

diameter/mm

Welding

wire diameter/mm

Welding current/A

Welding

current/A

Arc

voltage/V

Argon flow

1

rate/L•min-

Welding

1

rate/cm•min-

38

42

60

76

108

133

159

219

273

325

2.0

2.0

2.0

2.5

2.5

2.5

2.5

2.5

2.5

2.5

8

8

8

8~10

8~10

8~10

8~10

8~10

8~10

8~10

2

2

2

2.5

2.5

2.5

2.5.

2.5

2.5

2.5

75~90

75~95

75~100

80~105

90~110

90~115

95~120

100~ 120

110~ 125

120~ 140

11~13

11~13

11~13

14~16

14~16

14~16

14~16

14~16

14~16

14~16

6~8

6~8

7~9

8~10

9~11

10~12

11~13

12~14

12~14

12~14

4~5

4~5

4~5

4~5

5~6

5~6

5~6

5~6

5~6

5~6

Notice: the above parameters originate from <<Welding Dictionary>> P167,

Volume 1 of Edition 2.

TIG of stainless steel(single run welding)

Workpiece

thickness

/mm

Joint form

tungsten

electrode

diameter

/mm

welding

wire

diameter

/mm

Argon gas

flow rate/

1

L•min-

welding

current

(DCEP)

Welding

speed/

cm•min-1

0.8

1.0

1.5

1.5

2.4

2.4

3.2

3.2

4.8

4.8

6.0

Butt joint

Butt joint

Butt joint

Corner joint

Butt joint

Corner joint

Butt joint

Corner joint

Butt joint

Corner joint

Butt joint

1.0

1.6

1.6

1.6

1.6

1.6

1.6

1.6

2.4

3.2

4.0

1.6

1.6

1.6

1.6

2.4

2.4

2.4

2.4

3.2

3.2

4.0

5

5

7

7

7

7

7

7

8

9

10-12

20~50

50~80

65~105

75~125

85~125

95~135

100~135

115~145

150~225

175~250

220~300

66

56

30

25

30

25

30

25

25

20

25

Notice: the above parameters originate from <<Welding Dictionary>> P150,Volume 1 of Edition 2.

4.5 MMA basic welding technique

Arc Welding Practice

The techniques used for arc welding are almost identical regardless of what types of

metals are being joined. Naturally enough, different types of electrodes would be used

for different metals as described in the preceding section.

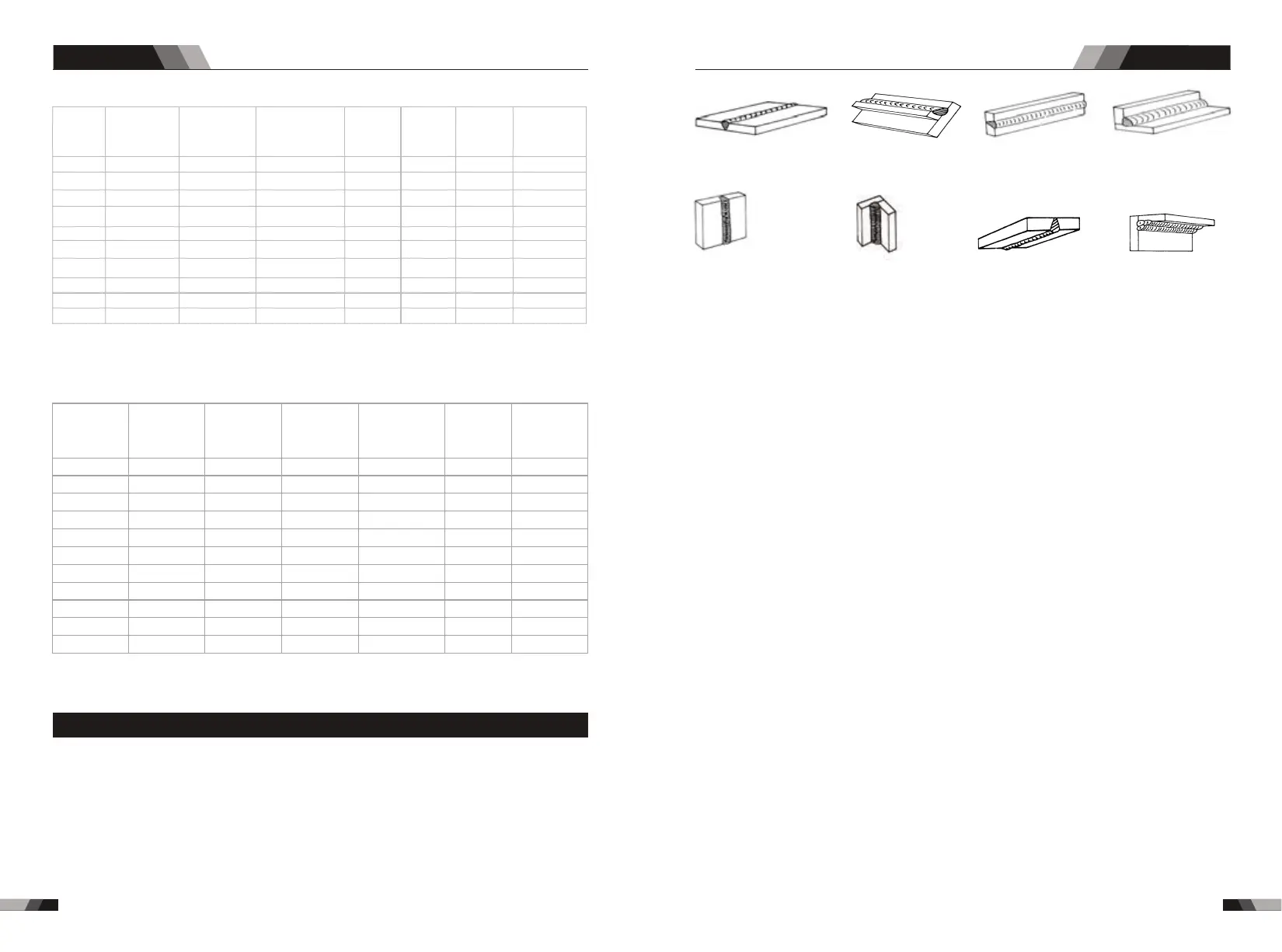

Welding Position

The electrodes dealt with in this publication can be used in most positions, i.e. they

are suitable for welding in flat, horizontal, vertical and overhead positions. Numerous

applications call for welds to be made in positions intermediate between these. Some

of the common types of welds are shown

Flat Position,

Down Hand Butt Weld

Flat Position,

Gravity Fillet Weld

Horizontal Position,

Butt Weld

Horizontal-Vertical

(HV) Position

Vertical Position,

Butt Weld

Vertical Position,

Fillet Weld

Vertical Position,

Fillet Weld

Overhead Position,

Fillet Weld

Welding techniqueWelding technique

65

66

Joint Preparations

In many cases, it will be possible to weld steel sections without any special preparation.

For heavier sections and for repair work on castings, etc., it will be necessary to cut or grind

an angle between the pieces being joined to ensure proper penetration of the weld metal

and to produce sound joints.

In general, surfaces being welded should be clean and free of rust, scale, dirt, grease, etc.

Slag should be removed from oxy-cut surfaces.

Arc Welding Technique - A Word to Beginners

For those who have not yet done any welding, the simplest way to commence is to run beads

on a piece of scrap plate. Use mild steel plate about 6.4mm (1/4") thick and a 3.2mm (1/8")

electrode. Clean any paint, loose scale or grease off the plate and set it firmly on the work

bench so that welding can be carried out in the downhand position. Make sure that the work

clamp is making good electrical contact with the work, either directly or through the work

table. For light gauge material, always clamp the work lead directly to the job, otherwise

a poor circuit will probably result.

The Welder

Place yourself in a comfortable position before beginning to weld. Get a seat of suitable

height and do as much work as possible sitting down. Don't hold your body tense. A taut

attitude of mind and a tensed body will soon make you feel tired. Relax and you will find

that the job becomes much easier. You can add much to your peace of mind by wearing

a leather apron and gauntlets. You won't be worrying then about being burnt or sparks

setting alight to your clothes.

Place the work so that the direction of welding is across, rather than to or from your body.

The electrode holder lead should be clear of any obstruction so that you can move your

arm freely along as the electrode burns down. If the lead is slung over your shoulder,

it allows greater freedom of movement and takes a lot of weight off your hand. Be sure the

insulation on your cable and electrode holder is not faulty, otherwise you are risking an

electric shock.

DC TIG SERIES EQUIPMENTDC TIG SERIES EQUIPMENT

Loading...

Loading...