4.3 The explanation of welding quality

The relation of welding area color & protect effect of stainless steel

Protect effect

best better

good

bad

worst

Welding area color argent,golden

blue

red-grey

grey

black

a butt joint b lap joint c coner joint d T joint

4.2 Joint froms in TIG

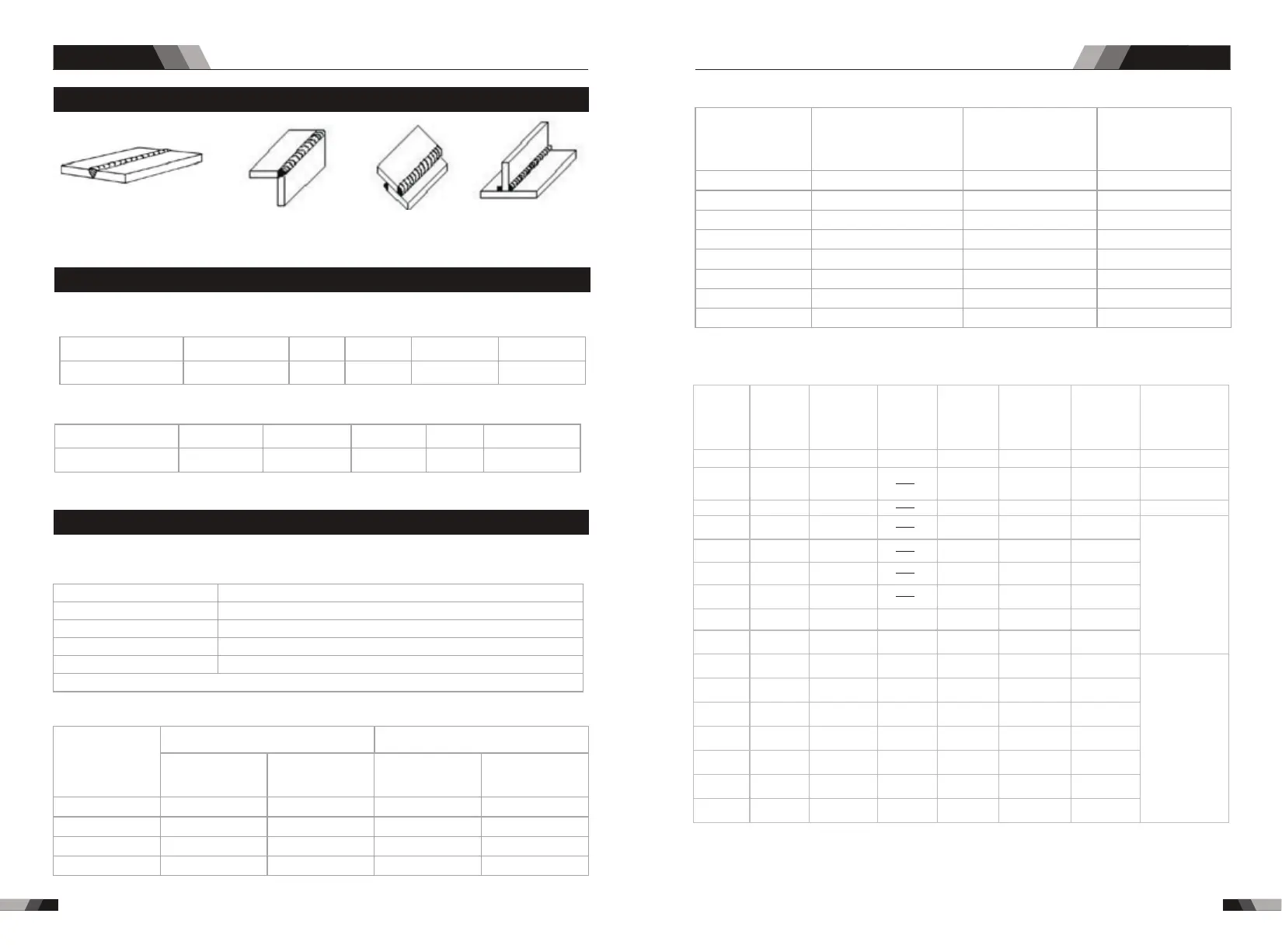

4.4 TIG parameters matching

The corresponding relationship between gas nozzle

diameter and electrode diameter

Gas nozzle diameter/mm

6.4

8

9.5

11.1

Electrode diameter/mm

0.5

1.0

1.6 or 2.4

3.2

Notice: the above parameters originate from <<Welding Dictionary>> P142,Volume 1 of Edition 2.

04

Gas nozzle and the shield gas flow rate

Welding

current range/A

DC positive connection

AC

Gas nozzle

diameter/mm

Gas flow

1

rate/L•min-

Gas nozzle

diameter/mm

Gas flow

1

rate/L•min-

10~100

101~150

151~200

201~300

4~9.5

4~9.5

6~13

8~13

4~5

4~7

6~8

8~9

8~9.5

9.5~11

11~13

13~16

6~8

7~10

7~10

8~15

Notice: the above parameters originate from <<Welding Dictionary>> P149,Volume 1 of Edition 2.

Protect effect

best better

good

bad

worst

Welding area color bright argent orange-yellow

blue-purple

caesious

white powder

of titanium oxid

The relation of welding area color & protect effect of Ti-alloy

Tungsten

Electrode

Diameter/mm

Sharpened of

the Electrode

Diameter/mm

Angle of Cone(º)

Background

Current/a

1.0

1.0

1.6

1.6

2.4

2.4

3.2

4.0

0.125

0.25

0.5

0.8

0.8

1.1

1.1

1.5

12

20

25

30

35

45

60

90

2~15

5~30

8~50

10~70

12~90

15~150

20~200

20~300

Tungsten Electrode

Welding techniqueWelding technique

63

64

Notice: the above parameters originate from《Welding Dictionary》P538,

Volume 2 of Edition 2.

Parameters of AC TIG(MMA) for Aluinum and its alloy

Steet

thickness

/mm

Welding

wire

diameter

/mm

Tungsten

eletrode

diameter

/mm

Pre-heat

Temper

-ature/ºC

Welding

current/A

Argon flow

1

rate/L•min-

Gas nozzle

diameter

/mm

Remark

1.6

1.6~2.0

2~2.5

2~3

3

3~4

4

4~5

4~5

2

2

2~3

3

4

4

5

5

5

100

100~150

45~60

50~80

90~120

150~180

180~200

180~240

240~280

260~320

280~340

1

1.5

2

3

4

5

6

8

10

7~9

7~9

8~12

8~12

10~15

10~15

16~20

16~20

16~20

8

8

8~12

8~12

8~12

10~12

14~16

14~16

14~16

Flange welding

Flange or butt

welding by

one side

Butt welding

V-groove

butt welding

12

14

16

18

20

16~20

22~25

4~5

5~6

5~6

5~6

5~6

5~6

5~6

5~6

5~6

6

6

6

6

6~7

150~200

180~200

200~220

200~240

200~260

200~260

200~260

300~360

340~380

340~380

360~400

360~400

300~380

360~400

18~22

20~24

20~24

25~30

25~30

25~30

30~35

16~20

16~20

16~20

16~20

20~22

16~20

20~22

X-groove

butt welding

DC TIG SERIES EQUIPMENTDC TIG SERIES EQUIPMENT

Loading...

Loading...