55

56

Operation

Operation

2.Initial Current

WIG 200D / CT 520PD: The main current Setting range 10AMP to 200AMP

This parameter operates in TIG modes and is used to set the starting current of TIG. The Start

Current remains on until the torch trigger switch is released after it has been depressed. (Can

be set in 2T or 4T mode.)

Note: The maximum initial current available will be limited to the set value of the base.

3.Up Slope

WIG 200D / CT 520PD: Setting ranges :0.1S-10S (0.1S increments)

This parameter operates in TIG modes only and is used to set the time for the weld current

to ramp up, after the torch trigger switch has been pressed then released, from Initial Current

to High or base current. (Can be set in 2T or 4T mode.)

4.Peak Current

WIG 200D / CT 520PD: Setting ranges

10AMP to 200AMP (DC TIG mode), 10 to 170A (STICK mode)

This parameter sets the TIG weld current. This parameter also sets the STICK weld

current.

6.Down Slope

WIG 200D / CT 520PD: Setting ranges 0.1-10s

This parameter operates in TIG modes only and is used to set the time for the weld current

to ramp down, after the torch trigger switch has been pressed to end current. This control

is used to eliminate the crater that can form at the completion of a weld.

5. Remote Control

The system independently identifies the remote control, and when the indicator light is

on, the welding current can be adjusted by remote (foot or welding gun).

7.End current

WIG 200D / CT 520PD: Setting ranges 10A-200A

This parameter operates in TIG modes only and is used to set the finish current for TIG. The

end Current remains ON until the torch trigger switch is released after it has been depressed.

(Can be set in 2T or 4T mode.)

Note: The maximum crater current available will be limited to the set value of the base

current.

8.Post Flow

WIG 200D / CT 520PD: Setting ranges 1-10S

This parameter operates in TIG modes only and is used to adjust the post gas flow time

once the arc has extinguished. This control is used to dramatically reduce oxidation of

the tungsten electrode.

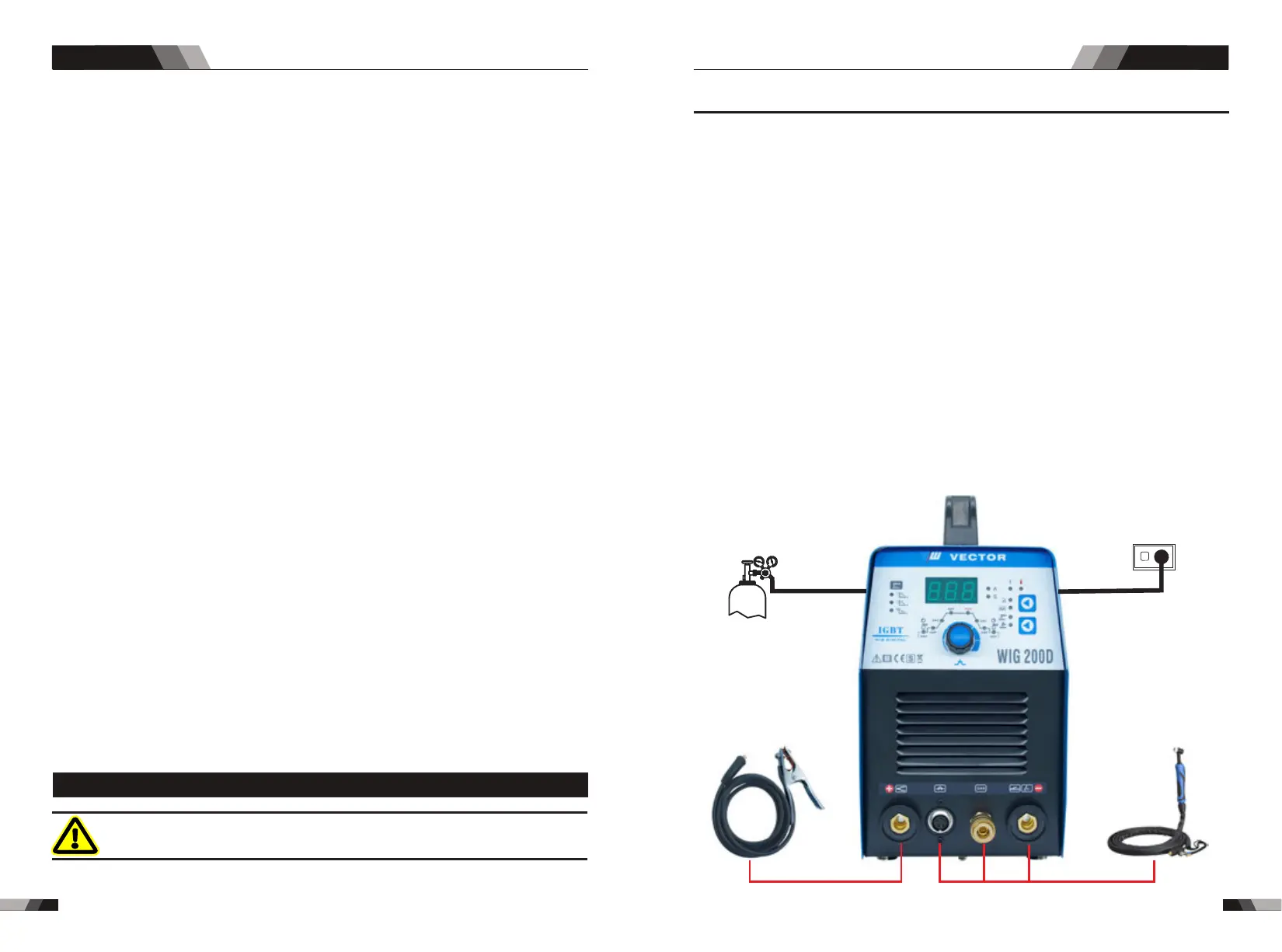

3.3 Set-up for LIFT TIG (GTAW) welding

WARNING

Before any welding is to begin, be sure to wear all

appropriate and recommended safety equipment.

NOTE

The following set up is known as Straight Polarity or DC electrode positive. This is commonly

used for DC LIFT TIG welding on most materials such as steel and stainless steel.

1. Switch the ON/OFF Switch (located on the rear panel) to OFF.

2. Connect the work lead cable to the positive output terminal, and the LIFT TIG Torch cable

to the negative output terminal.

3. Connect the gas line/hose to the proper shielding gas source.

4. Slowly open the Argon Cylinder Valve to the fully open position.

5. Connect the work lead clamp to your work piece.

6. The tungsten must be ground to a blunt point (similar to a pencil) in order to achieve optimum

welding results. See illustration. It is critical to grind the tungsten electrode in the direction

the grinding wheel is turning. Grind at a 30 degree angle and never to a sharp point.

7. Install the tungsten with approximately 1.6mm to 3.2mm sticking out from the gas cup,

ensuring you have correct sized collet.

8. Tighten the back cap.

9. Turn the switch to the “ON” position. The power L.E.D. light should illuminate.

10. Set the welding process to LIFT TIG.

11. Set the Weld Current Control Knob to the desired amperage.

12. You are now ready to begin LIFT TIG Welding.

Arg./Gas (TIG/WIG)

power supply

Earth Clamp

TIG Torch

DC TIG SERIES EQUIPMENTDC TIG SERIES EQUIPMENT

Loading...

Loading...