Installation Installing the Pump

18

Separation of Zone 0 and Zone 1 is accomplished by the male connector partition wall

between the packer and manifold connection. Connection of the UMP wiring is within

the Zone 0 boundary and Increased Safety measures inside the flameproof enclosure

must be ensured during field wiring connections.

13. Connect like colored wires from the UMP to like colored wires to the male connector with supplied Thomas &

Betts #T&B RBB217 butt splice connectors and making a mechanical crimp.

14. Pull on each wire to verify a reliable crimp was achieved.

15. Insulate the three connections by placing each by itself into an epoxy sealant bag following steps A, B, C

below.

16. When finished sealing the wires, coil the wires inside the packer's wiring compartment as neatly as possible

(see Figure 13). For clarity, the epoxy packs are shown transparent.

17. Lubricate the O-ring on the packer wiring compartment cover (with lifting eyebolt) with petroleum based jelly.

Screw in the packer wiring compartment cover (thread sealant should not be used). Torque to 35 ft-lbs (50

N•m).

Confirm that the lifting eyebolt is properly torqued to 10 ft-lbs (13.6 N•m) with a mini-

mum of 6 full threads installed. Occasionally, eyebolts are removed after pump instal-

lation and corrosion may occur in the threaded areas of the wiring compartment cover

(eyebolt plug) and the eyebolt. If corrosion has occurred, the cover and eyebolt should

be replaced.

18. Utilize the lifting eyebolt to suspend the pump vertically and then install the pump onto the riser pipe using UL

classified for petroleum, non-setting thread sealant until watertight and align appropriately to connect to the

product line piping.

When servicing equipment, use non-sparking tools and use caution when removing or

installing equipment to avoid generating a spark.

To male

connector

Tie wrap

Butt splice

From pigtail

ACB

Wire insulation is

fully into epoxy

Only one

connection

per bag.

Instructions:

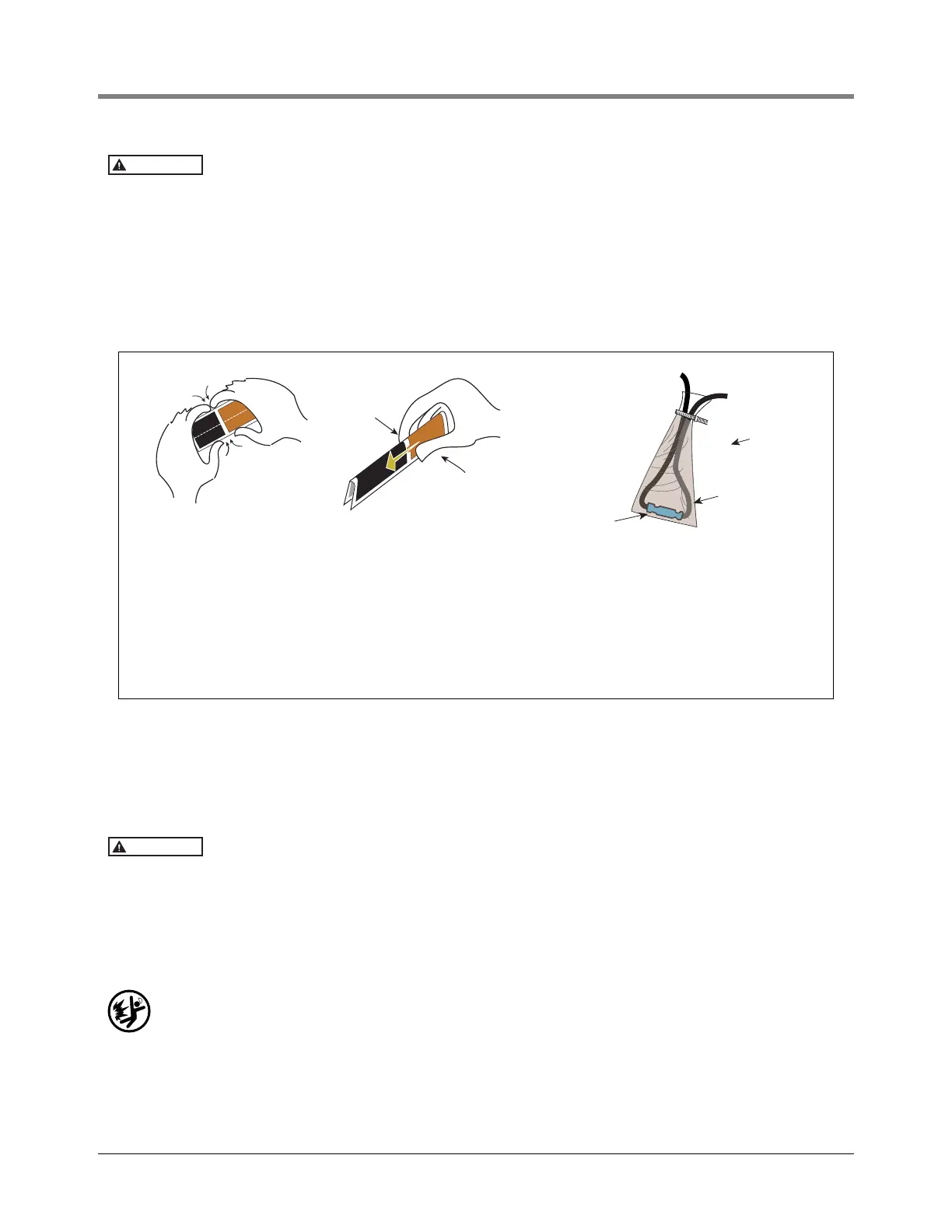

NOTE: When temperature is below 50°F (10°C), keep

resin in a warm place prior to mixing (e.g., in an

inside pocket next to body).

1. Open epoxy sealant package, and remove resin pak.

2. Holding resin pak as shown in A, bend pak along

long length.

3. As shown in B, firmly squeeze the RED SIDE of the

resin, forcing it through the center seal and into

BLACK SIDE.

4. Mix thoroughly to a uniform color by squeezing

content

s back and forth 25-30 times.

5. Squeeze mixed, warm resin into one end of bag and

cutoff other end.

6. Slowly insert wiring connection into sealing pack until

it is snug against the opposite end as shown in C.

7. Twist open end of bag and use tie wrap to close it off

and position the tie wrapped end up until the resin

gels.

Loading...

Loading...