SERVICE

Service - 56

Jump Starting Procedure

DANGER

The battery produces a ammable and explosive

gas. The battery may explode.

• Wear eye protection and gloves.

• Do not jump start a cold or frozen battery. Allow

the battery to warm up and inspect for cracks or

damage.

• Do not jump start a cracked or damaged bat-

tery.

• Do not attempt to jump start the power unit us-

ing a battery of a dierent voltage.

1. Inspect the discharged battery for terminal corro-

sion and loose connections. Clean the terminals

and tighten the connections prior to jump start-

ing.

2. Make sure the vehicle used to jump start the

power unit has a 12 volt, negative ground, electri-

cal system.

3. Pull the boosting vehicle up close to the disabled

power unit. Be sure the vehicles do not touch.

4. Shut o the boosting vehicle’s engine and engage

the parking brake.

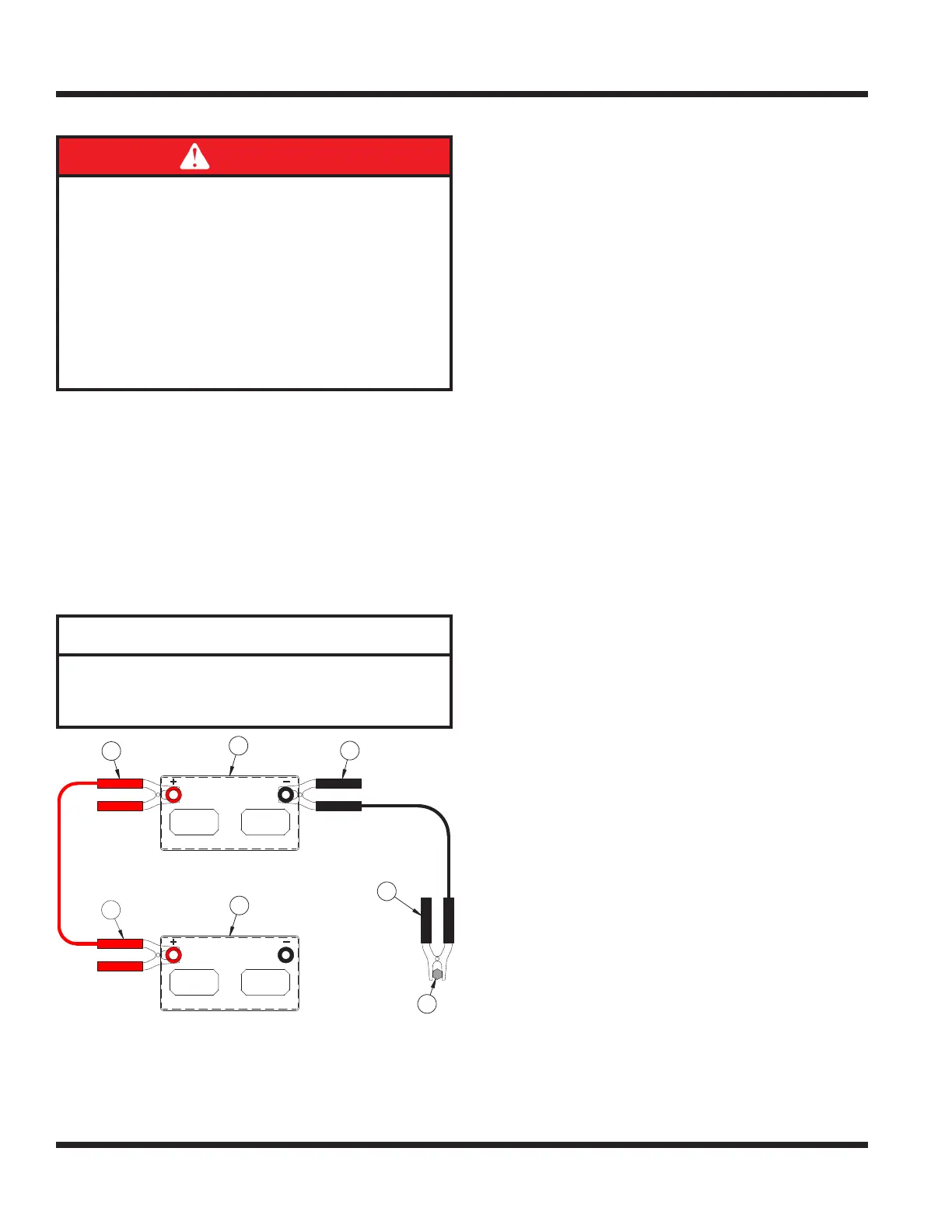

ATTENTION

Attempting to start the disabled unit with the boost-

ing vehicle’s engine running could cause damage to

the regulator.

5.

7

8

6

5

2

4

3

1

A B C D E F G H I J K

1

2

3

4

B

A

A. Discharged Battery

B. Booster Battery

C. Ground Stud

Connect one end of the positive (+) booster cable

to the positive (+) terminal (1) of the discharged

battery.

6. Connect the other end of the positive (+) booster

cable to the positive (+) terminal (2) of the boost-

er battery.

7. Connect the negative (-) booster cable to the

negative (-) terminal (3) of the booster battery.

8. Connect the other end of the negative (-) booster

cable to the disabled power unit’s ground stud (4).

9. Start the disabled power unit and remove the

booster cables in reverse order of installation

(negative booster cable rst).

TCM (Tractor Control Module) Explanation

The tractor control module controls the electronic

safety related functions of this power unit. Both solid

state and mechanical components are used to ensure

the safe, reliable operation of this machine.

This TCM monitors the electronic circuits necessary

for the engine, the starter, and the PTO to func-

tion. These input circuits include the PTO switch, the

neutral switch, the parking brake switch, the igni-

tion switch, and the seat switch. The TCM allows the

engine, the starter, or the PTO to operate only when

specic input criteria are satised. The engine, the

starter, and the PTO are controlled by outputs from

the TCM.

Loading...

Loading...