Vertiv™ | Liebert® DM | Appendix Manual

122

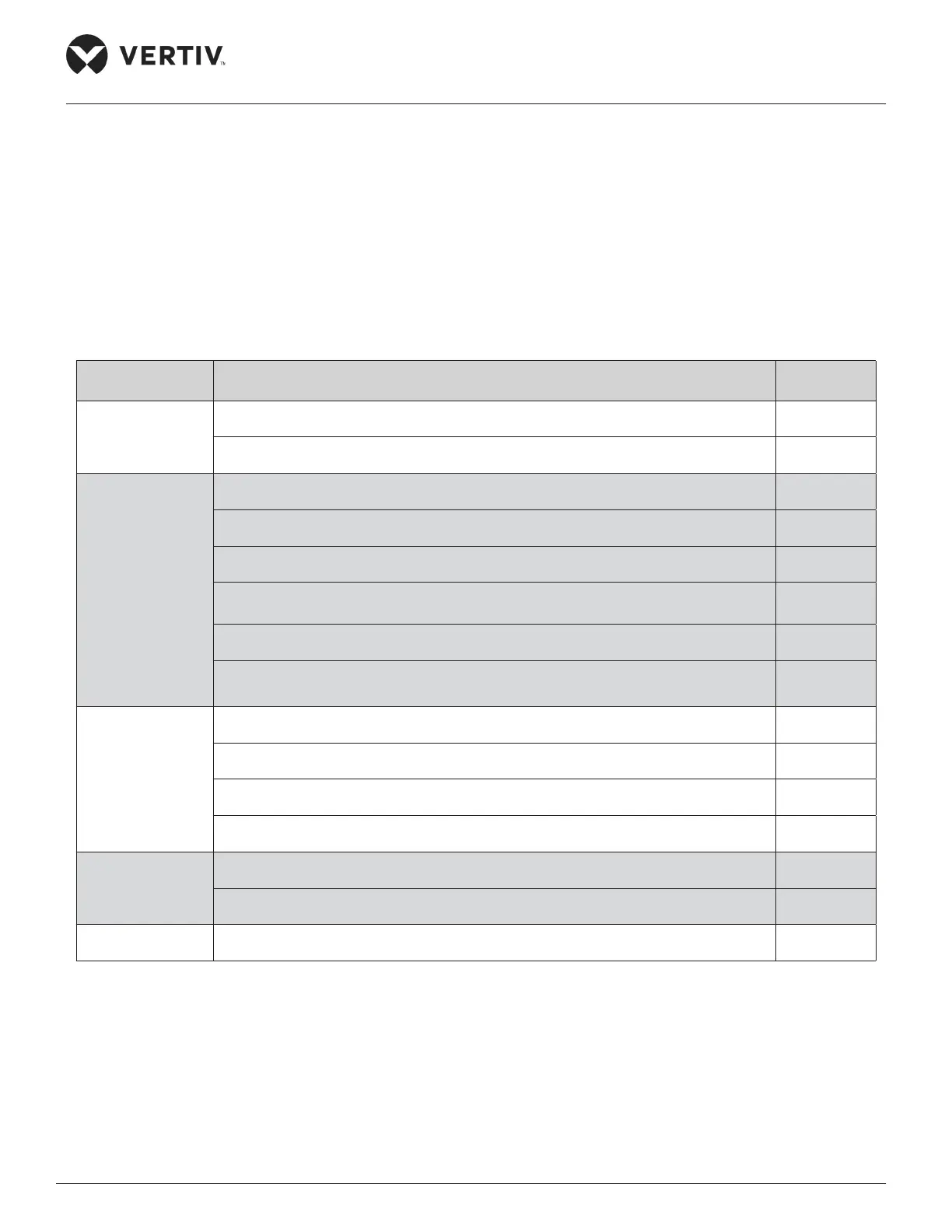

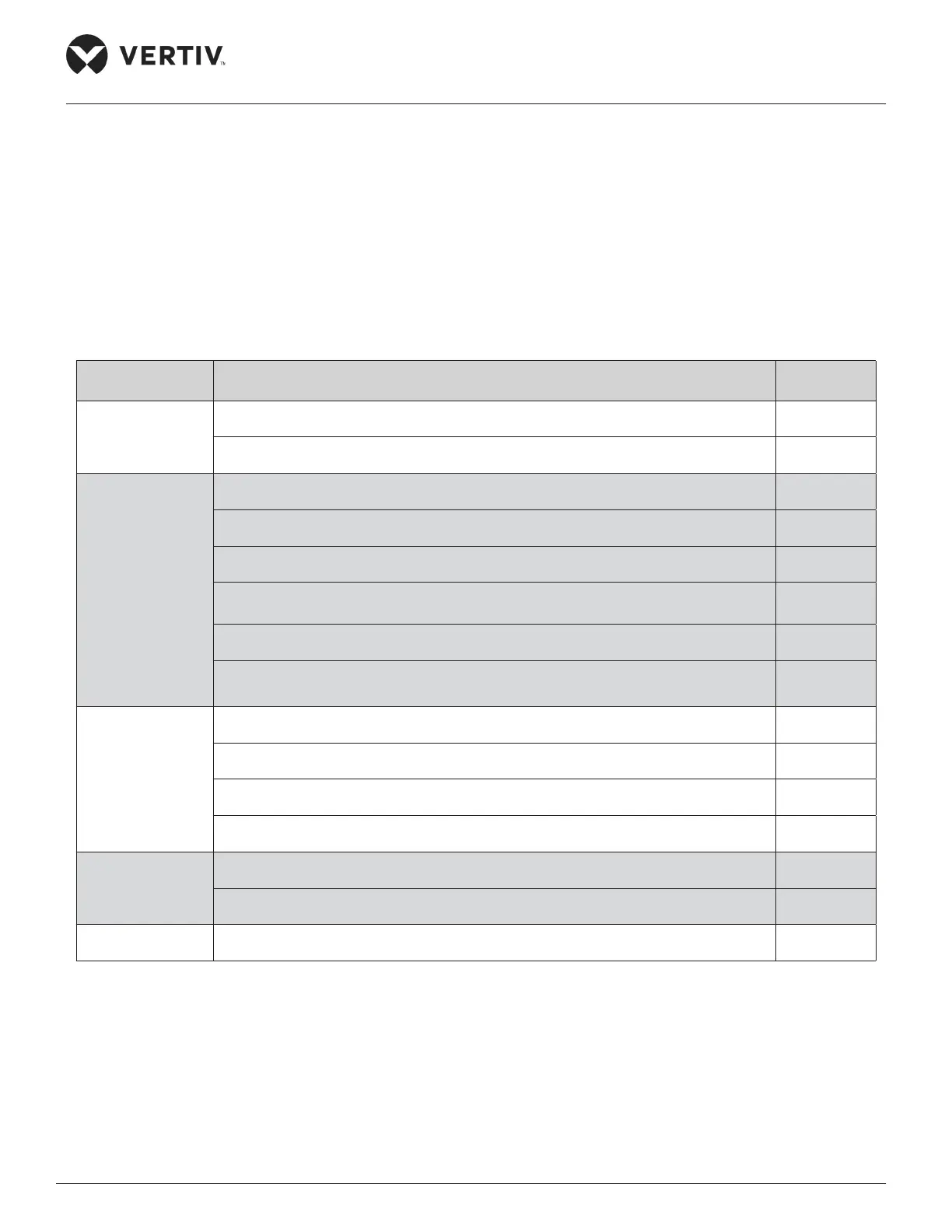

Appendix VI: Routine Maintenance Inspection Items

(Semi-annually)

Date: _____________________________ Prepared by: _____________________________

Model: _____________________________ Serial number: _____________________________

Routine Maintenance Inspection Items Checklist (Semi-annually)

Components Inspection Particular Remark

Compressor

Check for any signs of oil leaks

Listen to running sounds and observe operation vibrations

Refrigeration

cycle system

Check suction pressure, exhaust pressure and suction superheat are as per

setpoints

Check if the evaporator is functioning normally

Check system circulation and moisture content (observed through sight)

Check whether there is an obvious temperature dierence before and after

drying the filter

Check Thermal Expansion Valve (TXV) is firmly connected

Check the refrigerant piping. The refrigerant line must have a suitable bracket

and must not be placed against the wall, floor or fixed frame.

Air-cooled

condenser

Check if the condenser coil is clogged, clean immediately if it is blocked.

Check if the motor is firmly mounted

Check if there is any distortions in impeller rotation, also check bearings if they

are in good condition

Check if the refrigerant piping are properly supported

Electrical board

Check all electrical connections are firmly tightened

Check the surface of the circuit board for signs of corrosion

Electrical heater Check heating element for signs of corrosion or burning

Signature_________________________________________________________

Note: Please copy this table for record keeping purposes.

Loading...

Loading...