Vertiv | Liebert® DM | User Manual 98

System Operation and Maintenance

7.2.7. Thermal Expansion Valve (TXV)

The thermal expansion valve keeps the evaporator supplied with enough refrigerant to satisfy load conditions. Its proper

operation can be determined by measuring the superheat level. The correct superheat setting is 5.6 °C to 8.3 °C

(10 °F to 15 °F).

7.2.8. High-Pressure Switch and Low-Pressure Switch

The discharge and suction pressures will vary greatly with the unit load and ambient conditions, refer Table 7-1 for details of

normal operation. When the discharge pressure rises to the high-pressure setpoint, the high-pressure switch gets activated

and the control system shuts down the compressor after ensuring that an abnormal input signal of the high-pressure switch

is triggered.

When the suction pressure is lower than the low-pressure setting, the low-pressure switch gets activated and the control

system shuts down the cooling system after confirmation.

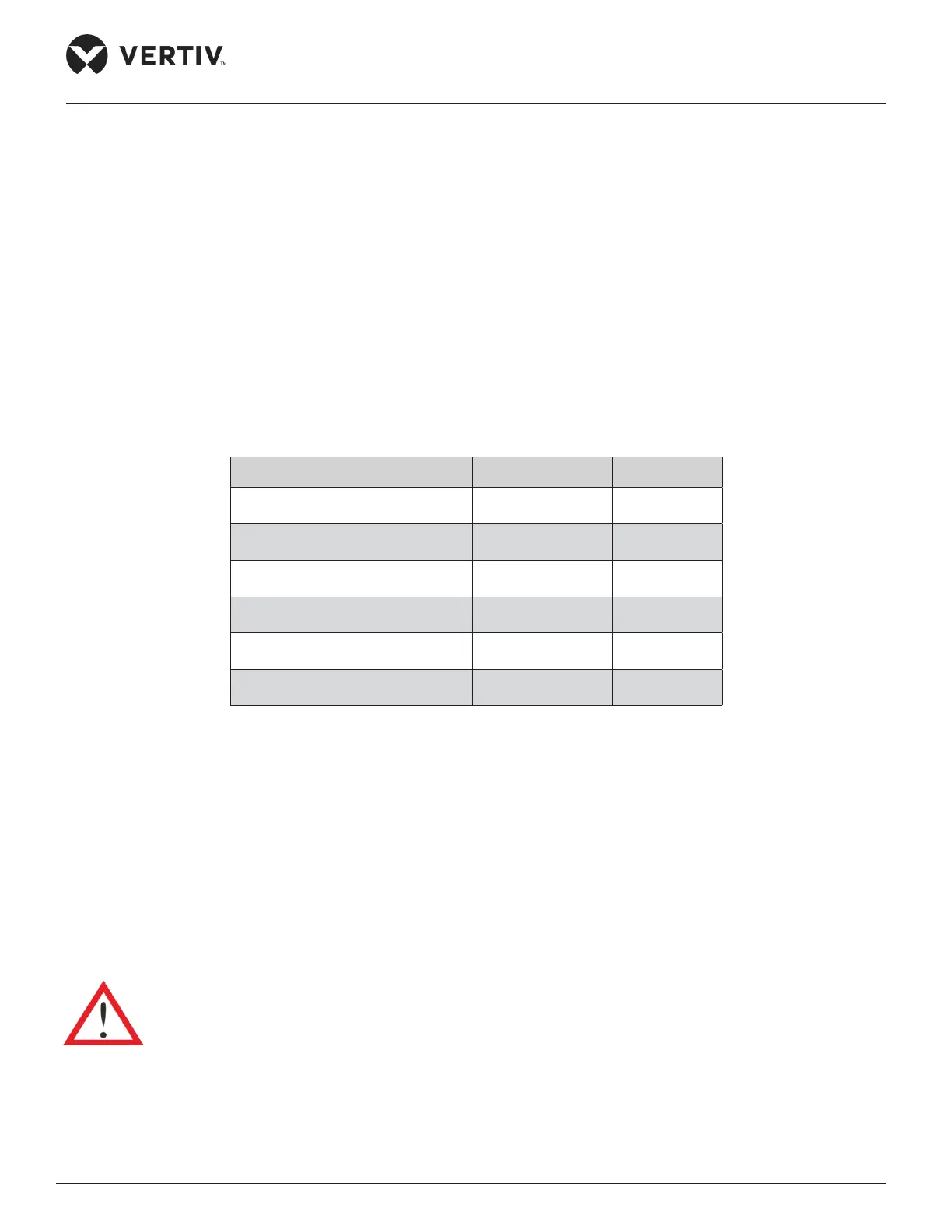

Table 7-1 Typical Discharge Pressure and Suction Pressure

Items psig MPa

Low pressure 100 to 159 0.7 to 1.1

Low-pressure setting 53 0.4

Low-pressure recovery point 80 0.6

High pressure 284 to 526 2.0 to 3.7

High-pressure setting 583 4.1

High-pressure recovery point 469 3.3

7.2.9. Compressor

The compressor fault is generally classified into two types:

1. Motor failure (such as winding burnout, insulation failure, short-circuit between coils and so on).

2. Mechanical failure (such as compressing failure, relief valve fault, therm-o-disc fault and so on).

If the suicient operating pressure is not established, it is an indication of the compressor has failed. It can be confirmed -

if the suction pressure and discharge pressure are balanced, and the motor does not rotate reversely.

The controller of the unit has a powerful alarm and protection functions to ensure safe operation of the compressor. The

maintenance personnel should record the high pressure and the low pressure, and find out the cause of an alarm protection

during periodical maintenance and inspection.

Avoid touching or contacting the residual gas and oils in compressor with exposed skin. Wear long rubber

gloves to handle contaminated components.

Loading...

Loading...