Vertiv | Liebert® DM | User Manual 22

Mechanical Installation

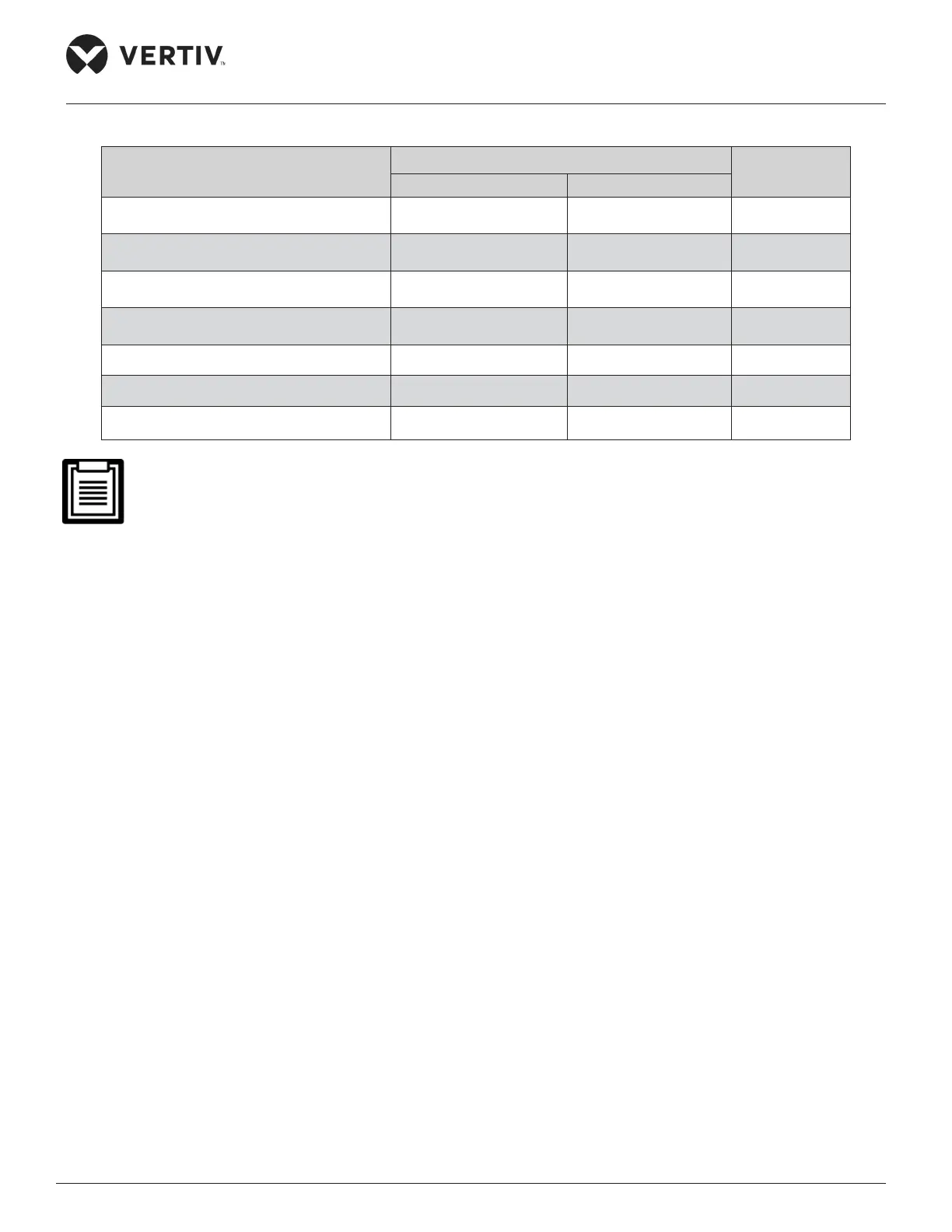

Table 2-2 Mechanical Parameters of Outdoor Unit

Model

Dimensions (W × D × H)

Operational

Weight (kg)

mm inch

DMC07WA1 (Vertical installation) 787×352×829 30.98x13.86x32.64 40

DMC12WA1 (Vertical installation) 787×352×1240 30.98x13.86x48.82 61

DMC17WA1(Vertical installation) 950×400×1245 37.40x15.75x49.02 85

DMC22MA1 (Vertical installation) 1133×520×1323 44.6x20.5x52.1 104

DMC22MA1 (Horizontal installation) 1305×1133×974 51.4x44.6x38.3 104

DMC27MA1 (Vertical installation) 1293×520×1491 50.9x20.5x58.7 120

DMC27MA1 (Horizontal installation) 1473×1293×974 57.9x50.9x38.3 120

• The indoor unit parameters do not include the size of shut o service angle valve.

• The horizontal installation parameters of the outdoor unit do not include the dimensions of brackets, shut

o service angle valves, protective nets, and support-leg.

• The vertical installation parameters of the outdoor unit do not include the dimensions of brackets, shut o

service angle valves, protective nets, and support-leg.

• The external dimensions are for reference only; if the application requirements are other than the standard

dimension, contact Vertiv representative.

• The operational weight of the unit includes the heater and the infrared humidifier, and does not include the

refrigerant charge inside the unit.

2.5. Installing Indoor Unit

2.5.1. Equipment Room Requirements

The equipment room must be prepared before installation to ensure a smooth operating flow and to achieve the expected

results. The data center must meet the standards to be properly ventilated and heated. The design specifications for the air

conditioners must be ideal and should correspond to energy-eicient design standards.

Following are the requirements to maintain a favorable room environment prior to the installation.

The equipment room should have suitable and eective heat insulation.

• The equipment room should have a sealed and damp-proof layer. Polyethylene film should be used for the damp proof

layer of the ceiling and walls. Alternatively, a moisture-proof paint can be used to simulate the same eect as that of

Polyethylene. It is important to ensure that the coating on the concrete wall and floor are damp-proof.

• Outdoor air significantly increases the load of heating, cooling, humidification and dehumidification. Therefore, all the

doors and windows must be closed. Gaps and seams must be very narrow to prevent the outdoor air from entering the

equipment room. It is an industry best practice to keep the infiltration of the outdoor air below 5% of the total indoor

airflow. Apply appropriate thermal insulation and antifreeze measures for outdoor water pipes to avoid poor drainage and

insuicient water supply caused by freezing.

Loading...

Loading...