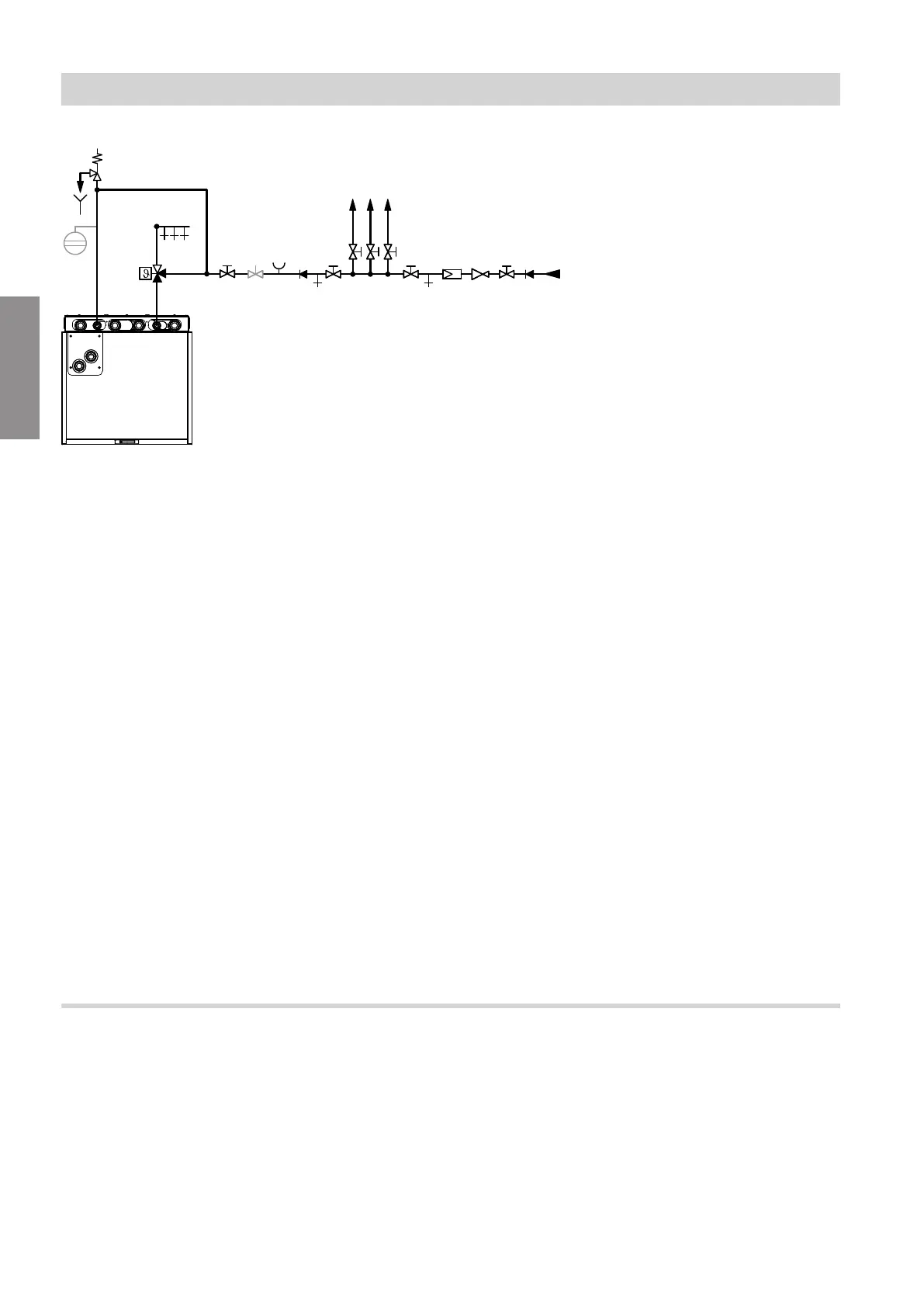

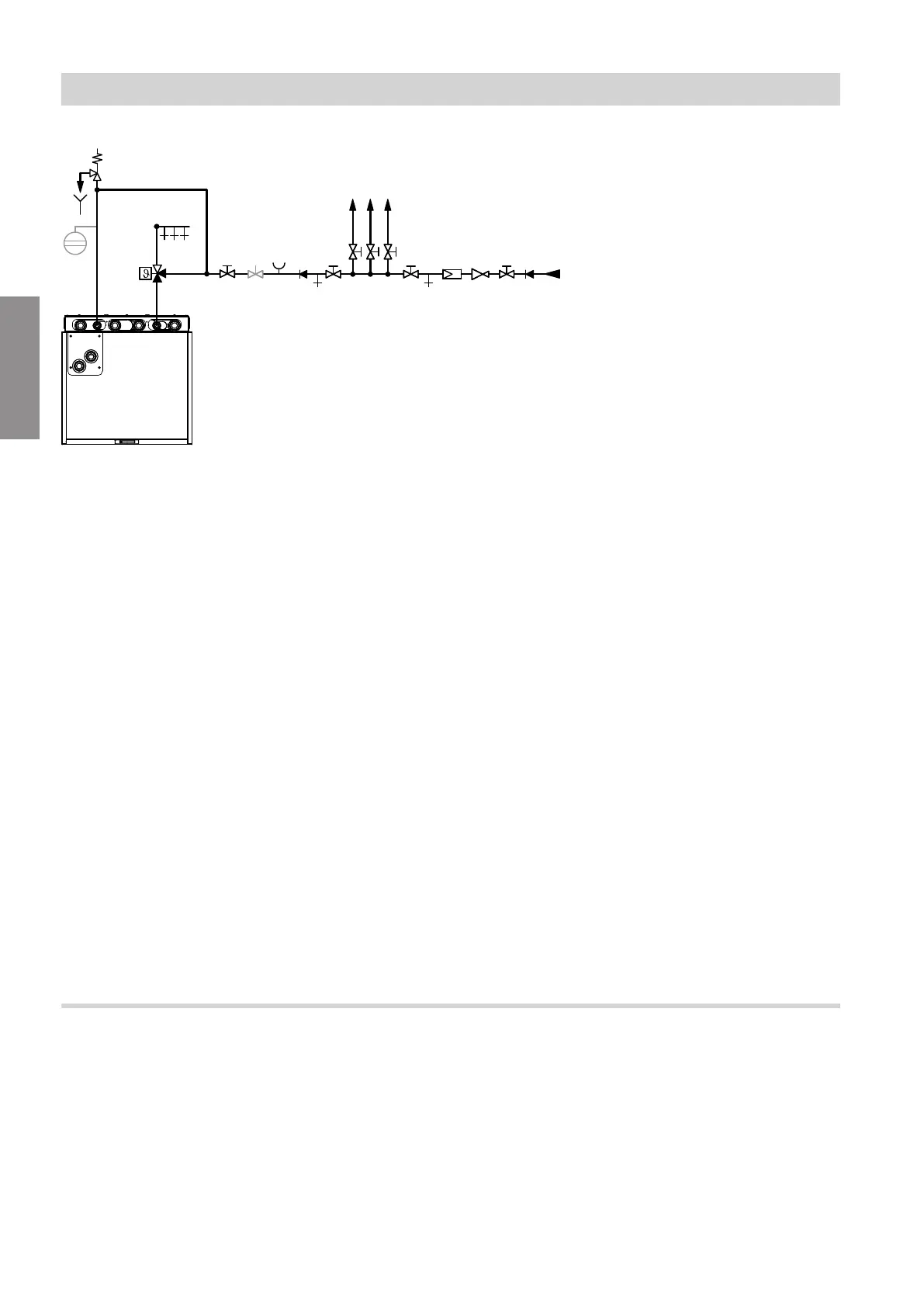

54

K

O

H

G F

L

O

F M N F K L

F

C

B

A

E

D

Fig. 39

A

Expansion vessel, suitable for drinking water

B

Visible discharge pipe outlet point

C

Safety valve

D

Automatic thermostatic mixing valve

E

DHW

F

Shut-off valve

G

Flow regulating valve

H

Pressure gauge connection

K

Non-return valve/pipe separator

L

Cold water

M

Drinking water filter

N

Pressure reducer to DIN 1988-200:2012-05

O

Drain valve

Safety valve

The DHW cylinder must have a safety valve to protect

against unduly high pressure.

Recommendation: Install safety valve above top edge

of cylinder. This means the DHW cylinder will not need

to be drained when working on the safety valve.

CH: According to W3 "Principles for creating potable

water installations", safety valves must be drained

directly via a visible unrestricted drain or via a short

outlet line to the drain network.

Drinking water filter

According to DIN 1988-2, a drinking water filter must

be installed in systems with metal pipework. Viess-

mann also recommends the installation of a drinking

water filter when using plastic pipes to DIN 1988 to

prevent contaminants entering the DHW system.

Automatic thermostatic mixing valve

With appliances that heat DHW to temperatures above

60 °C, an automatic thermostatic mixing valve must be

installed in the DHW line as protection against scald-

ing.

This also particularly applies when connecting solar

thermal systems.

Preparing the hydraulic connections

The following requirements must be met on site:

■

Components reflect current technology.

■

Components are approved in sealed unvented heat-

ing systems with operating pressures up to 3 bar.

■

Comply with manufacturer's instructions on installa-

tion.

Hydraulic connections

Hydraulic connection of the indoor unit (cont.)

6222080

Installation

Loading...

Loading...