Reduced internal shaft dimensions

System size A

External diameter;

female connection

Reduced internal shaft dimension

a b c

square or rectangular

(short side)

round

Ø mm mm Ø mm

80 94 120 135

100 128 150 165

Minimum dimension of shafts in which a flue may be used (positive

pressure operation) without separate calculation.

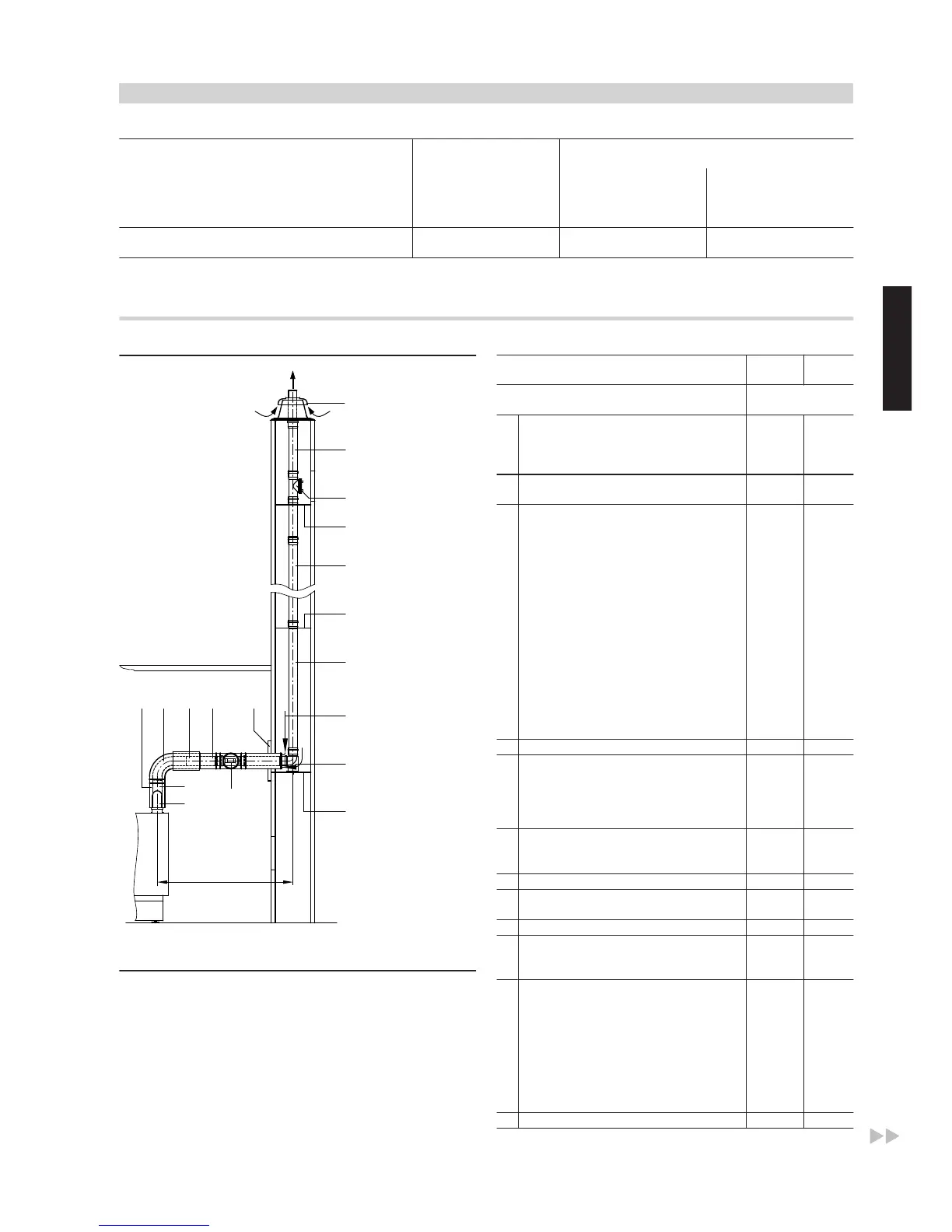

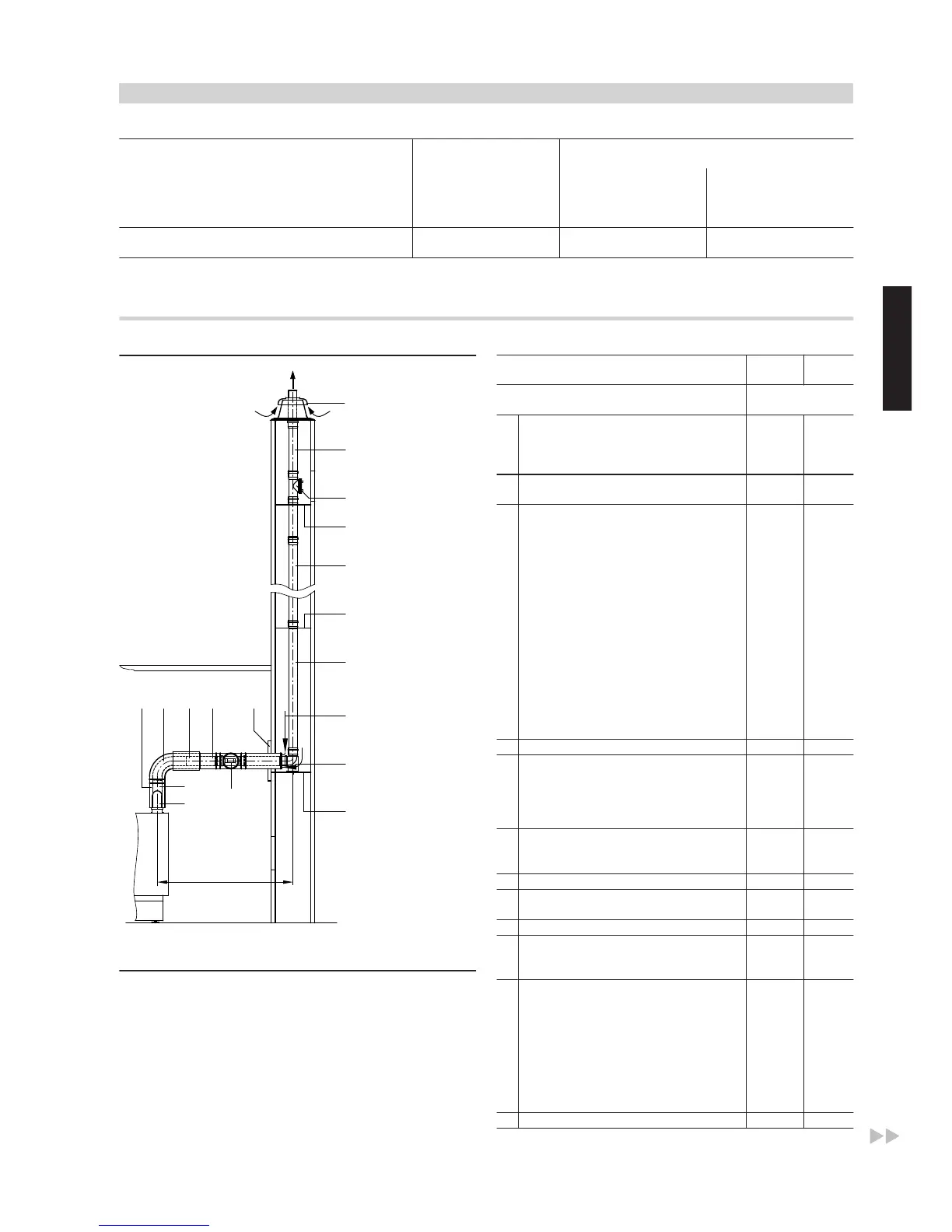

Flue, system size 80 and 100 (components) (type C

63x

to TRÖI 2009)

Illustration with the Vitoladens 300-C

A

Ventilation air

B

Flue gas

C

Inspection port

D

Connection piece

Rated heating output (kW) up to

35.4

from

42.8

System size

Ø mm

1

Boiler flue connection

For balanced flue operation and coaxial

balanced flue routing

(Part of the standard boiler delivery)

80/125 100/150

Balanced flue pipe

With test ports (160 mm long)

80/125 100/150

2

Standard shaft pack (PPs, rigid)

Comprising:

– Support bend

– Support rail

– Shaft cover (PPs)

– Spacers (5 pce, max. clearance 5 m)

or

80 100

Standard shaft pack (metal/PPs, rigid)

For twin flue chimneys; one flue for solid

fuel boilers

Comprising:

– Support bend

– Support rail

– Shaft cover (metal)

– Terminal pipe (stainless steel)

– Spacers (5 pce, max. clearance 5 m)

80 100

Spacers (3 pce, max. clearance 5 m) 80 100

3

Pipe 80 100

1.95 m long (2 pce = 3.9 mm)

1.95 m long (1 pce)

1 m long (1 pce)

0.5 m long (1 pce)

Bend (for use in corbelled chimneys)

30º (2 pce)

15º (2 pce)

80 100

4

Inspection piece, straight (1 pce) 80 100

5

Balanced flue inspection piece, straight

(1 pce)

80/125 100/150

6

Wall bezel 125 150

7

Balanced flue pipe

1 m long

0.5 m long

80/125 100/150

8

Balanced flue bend

87º (1 pce)

45º (2 pce)

or

80/125 100/150

Balanced flue inspection bend 87º

(1 pce)

or

80/125 —

Balanced flue inspection tee 87º

(1 pce)

— 100/150

9

Balanced flue slide coupling 80/125 100/150

Design and sizing information for the Vitoladens 300-C, -T, and Vitorondens 200-T, 222-F

(cont.)

VITOLADENS, VITORONDENS

VIESMANN

11

5822 452 GB

2

Loading...

Loading...