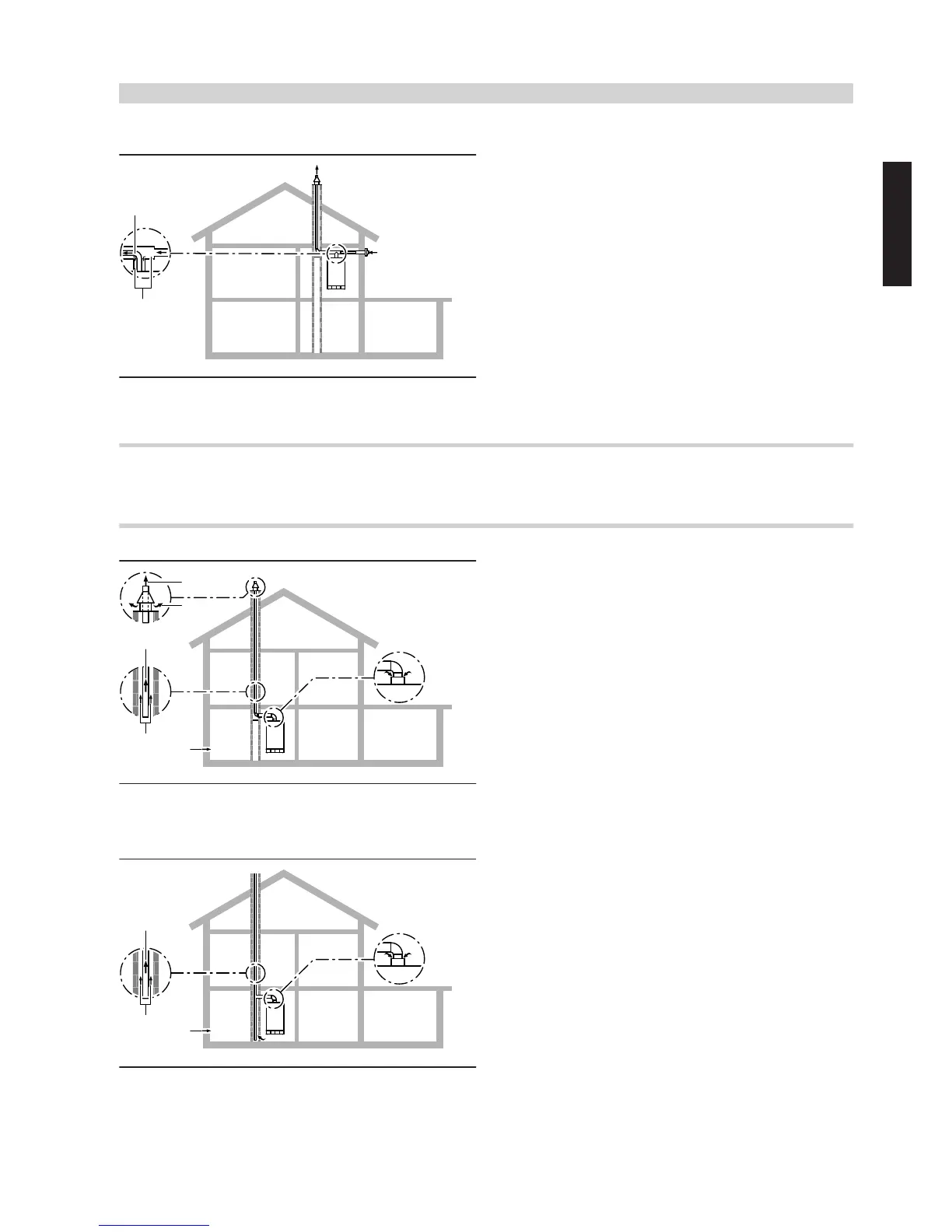

A

Flue gas

B

Ventilation air

Separate ventilation air and flue gas routing

(type C

83x

, to TRÖl 2009)

The boiler draws combustion air from outside via a separate supply

pipe routed through the external wall, and expels flue gas to the atmos-

phere via a shaft leading through the roof.

The connection piece to the chimney is designed as a coaxial pipe.

This balanced flue system is used if the existing chimney is unsuitable

for routing combustion air due to its dimensions or characteristics

(deposits).

For a detailed description, see page 31.

1.8 Flue installation options for open flue operation

(Separate ventilation air aperture with 150 cm

2

or 2 × 75 cm

2

cross-section required)

Shown with the Vitoladens 300-W.

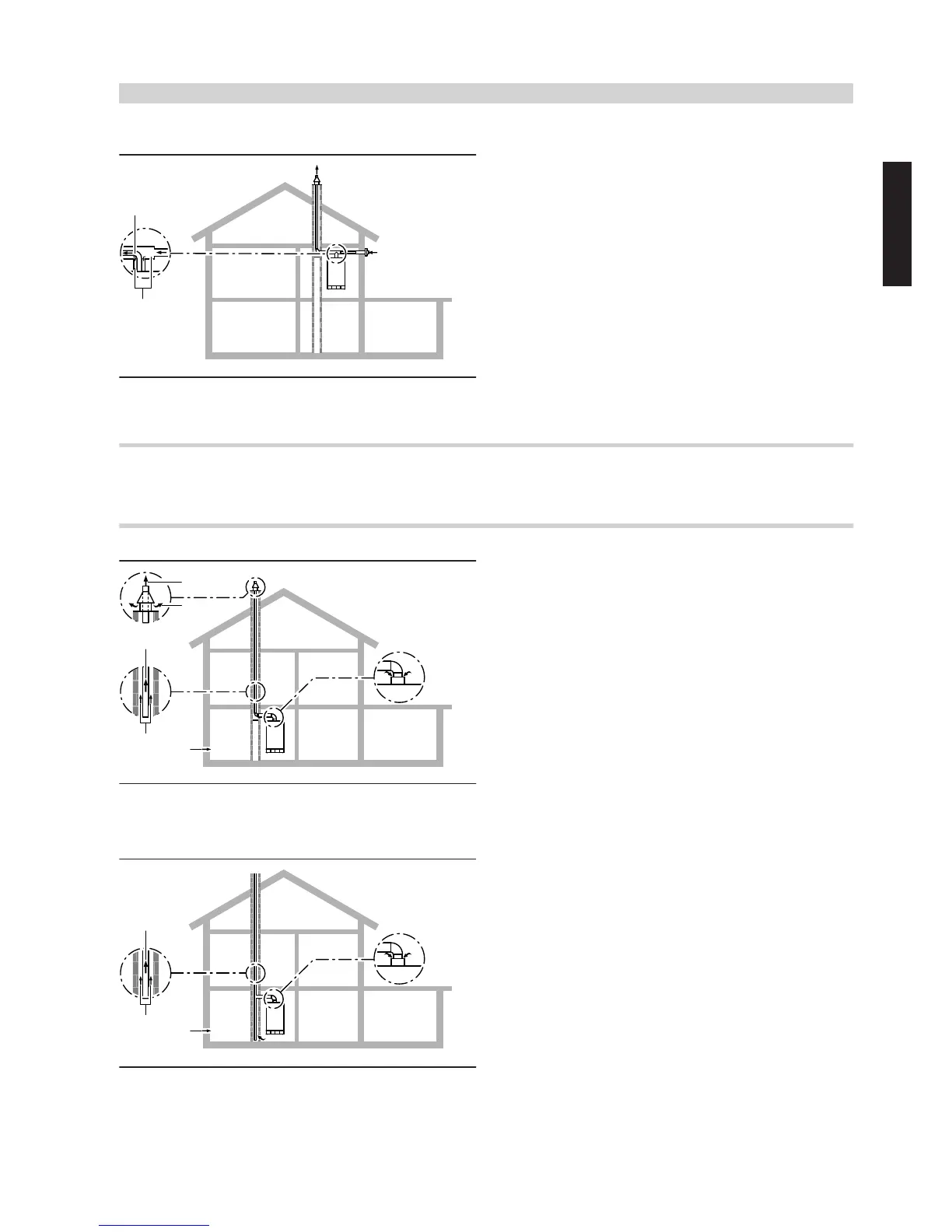

In an installation room (non-living space) with one or more full storeys above

A

Flue gas

B

Secondary ventilation

C

Ventilation air

Routing through a shaft

(type B

23

, to TRÖl 2009)

The boiler draws combustion air from the installation room and expels

flue gas through the flue via the roof (balanced flow).

For a detailed description, see page 34.

A

Flue gas

B

Secondary ventilation

C

Ventilation air

Connection to a moisture-resistant chimney (MR chimney)

(type B

23

, to TRÖl 2009)

The boiler draws combustion air from the installation room and routes

flue gas through the moisture-resistant chimney via the roof.

For a detailed description, see page 37.

Flue systems

(cont.)

VITOLADENS, VITORONDENS

VIESMANN

9

5822 452 GB

1

Loading...

Loading...