36

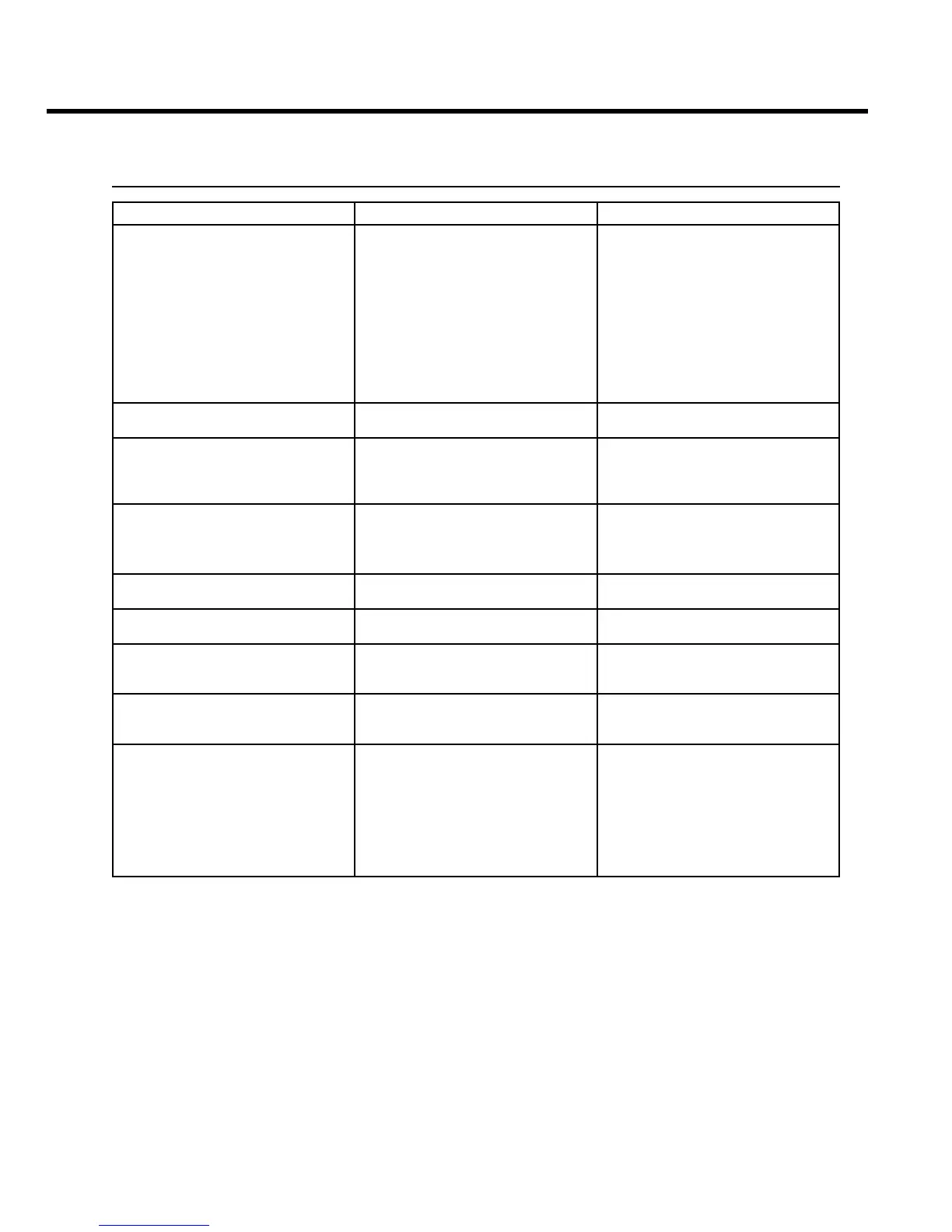

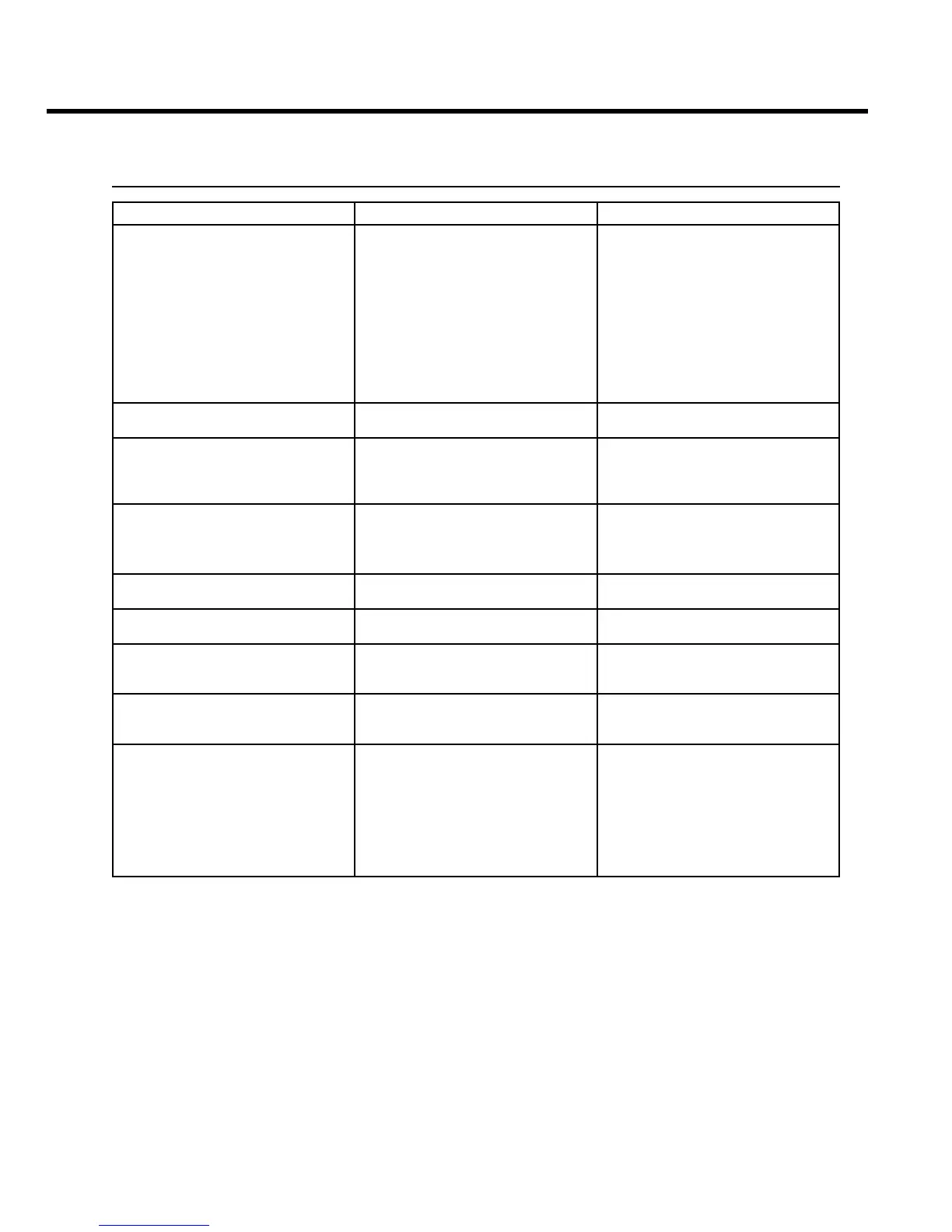

Troubleshooting Table (Continued)

Problem Possible Cause Correction

Compactor stops during operation. 1. Uneven load may cause trash

bucket to shift forward opening

the door.

1. Gently push the door closed

until the door actuator engages

the interlock switch. This will

activate the ram until it returns

to the up position. Open trash

bucket and reposition any

objects that may be causing the

uneven load.

2. Uneven load may cause ram to

wedge in trash basket.

2. It may be necessary to remove

cabinet and reverse screw

assemblies manually.

Compaction cycle repeats without

pressing START.

Control board defective. Replace control board or complete

display module assembly.

After pressing START and closing

the door, ram reverses direction

repeatedly for 3 seconds and shuts

o.

1. Lower limit switch defective. 1. Replace lower limit switch.

2. Centrifugal switch defective. 2. Replace centrifugal switch

assembly.

Ram runs down for 3 seconds and

motor stops.

1. Defective upper limit switch

assembly.

1. Replace upper limit switch

assembly.

2. Defective centrifugal switch. 2. Replace centrifugal switch

assembly.

Motor hums after ram returns to the

up position.

Defective upper limit switch

assembly.

Replace upper limit switch assembly.

Ram continues to run with the door

open.

Defective interlock switch. Replace interlock switch assembly.

Ram runs down and doesn’t return

up. Motor hums after reaching the

bottom position.

Defective upper limit switch

assembly.

Replace upper limit switch assembly.

Ram runs down and stops (operates

as it would in AUTO DELAY compact

mode).

Control board defective. Replace control board or complete

display module assembly.

Trash compactor noise level

increases during operation.

NOTE: Due to the number of moving

components, it is expected that

operating noise may increase over

the life of the product.

1. Worn or damaged drive

components.

1. Inspect power mechanism

and replace damaged or worn

components.

2. Lack of lubrication on moving

components.

2. Inspect power mechanism

and regrease components on

mechanism as necessary. It

is recommended to use high

quality wheel bearing grease.

Section E – Troubleshooting

Loading...

Loading...