21

C

D

A

e

f

d

a

b

c

d

c

g

± 1°

max

h

g

d

c

e

b

f

a

c

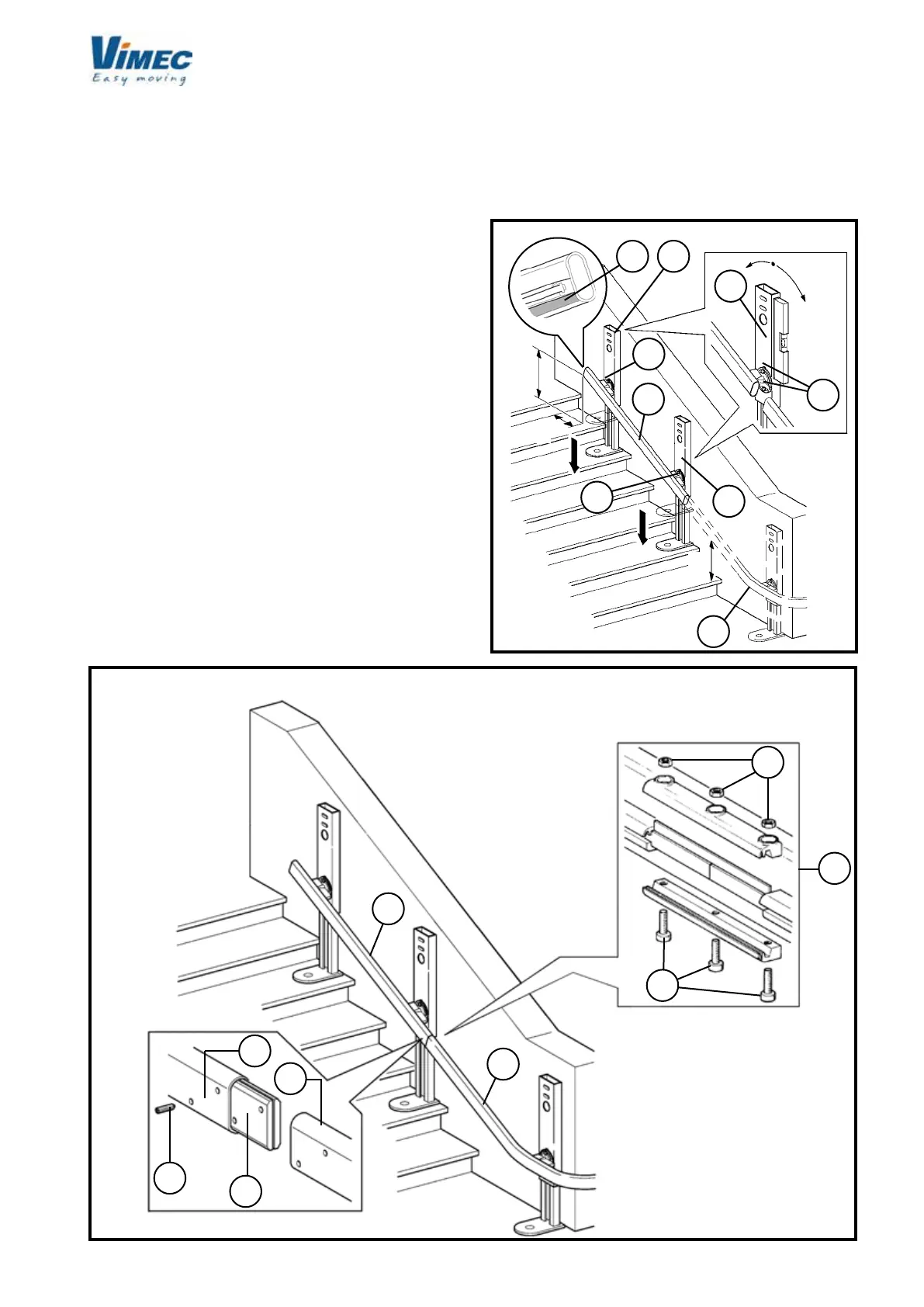

N.B.: Check that the part of the lower rail (Fig. 8/g)

on which the brushes operate is clean, and remove

any dirt if necessary.

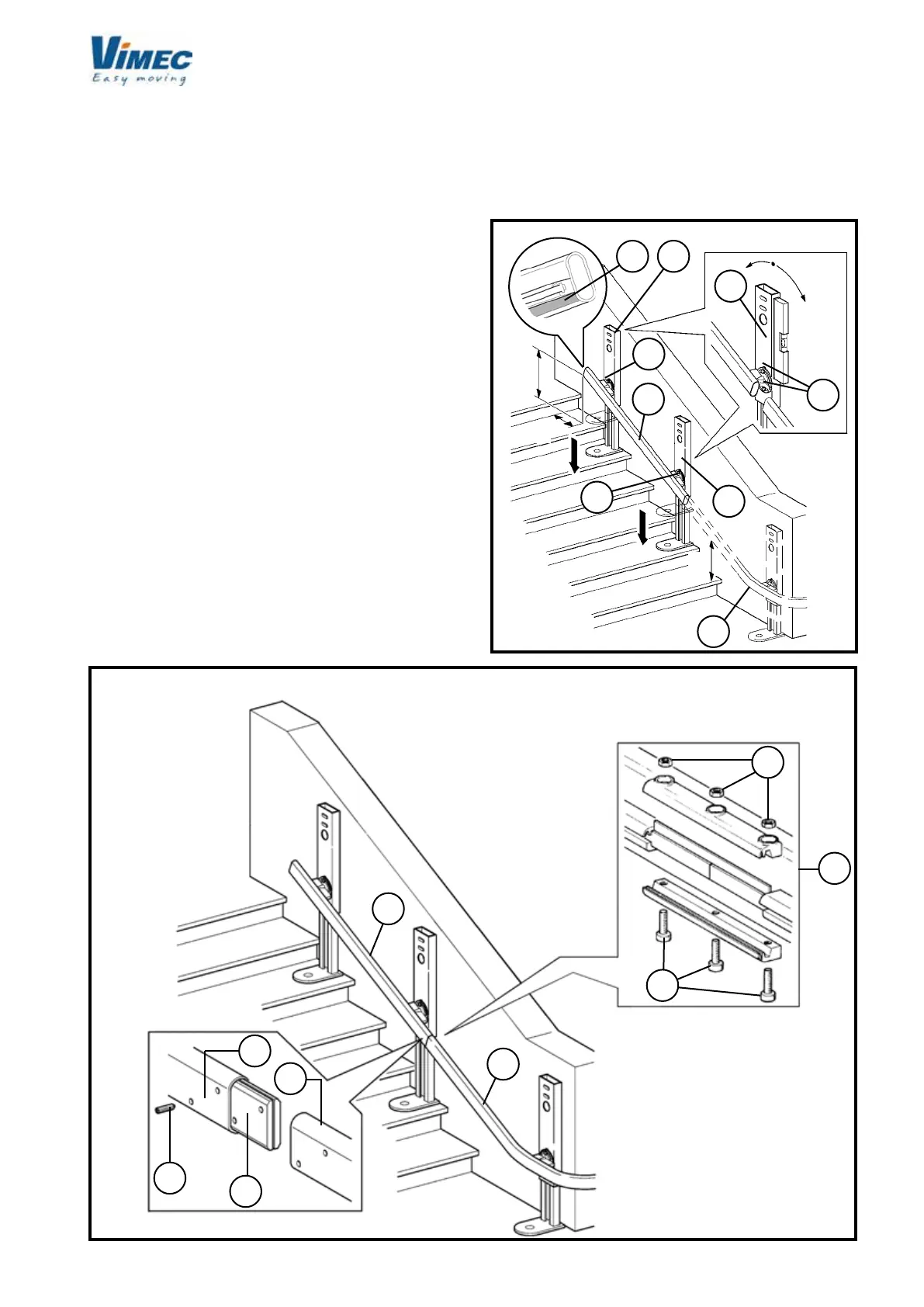

WARNING: The rail xing screws (Fig. 7/a) must be

tightened to a torque of 9-10 daNm.

- Use the assembly markings (Fig. 3/b) to identify the

section of rail with feet (Fig. 8/a) to be placed just

above the bend just installed (Fig. 8/b).

- Position the rail correctly for installation (Fig. 8/a),

referring to the dimensions shown in the installation

drawing (example Fig. 5), extract the feet and lightly

tighten just one bolt (Fig. 8/c) for each connection

xture (Fig. 8/d).

- Fit the joint plates (Fig. 9/e) into the tubular rail (Fig.

9/a) and lightly tighten the rst 2 dowels (Fig. 9/f).

- Place the lower section of rail (Fig. 9/b) in position, t

the other dowels and tighten to a torque of 4-5 daNm

after checking that the tubular rails are correctly ali-

gned and there is no gap between the rail sections.

Fit the busbar connection joint (if any) as shown (Fig.

9/d) after checking that the components are clean.

- As already done with the bend, install the connection

xtures (Fig. 8/e) in perfectly vertical position, by

tightening both xing screws (Fig. 8/f) after adjustment.

- Install all the remaining rail sections except the last

one as previously described, all the way down to the

bottom of the staircase.

FIG.8

FIG.9

± 1°

max

In order to make assembly for wall xing easier (Fig.

10/a), it is advisable the use of special test feet (Fig.

10/b) (contact Vimec’s assistance since they are

excluded from the supply) to be plugged into the rail

instead of the intermediate connections (about 1-2 per

each ramp).

Loading...

Loading...