29

d

b

d

b

c

a

c

a

b

d

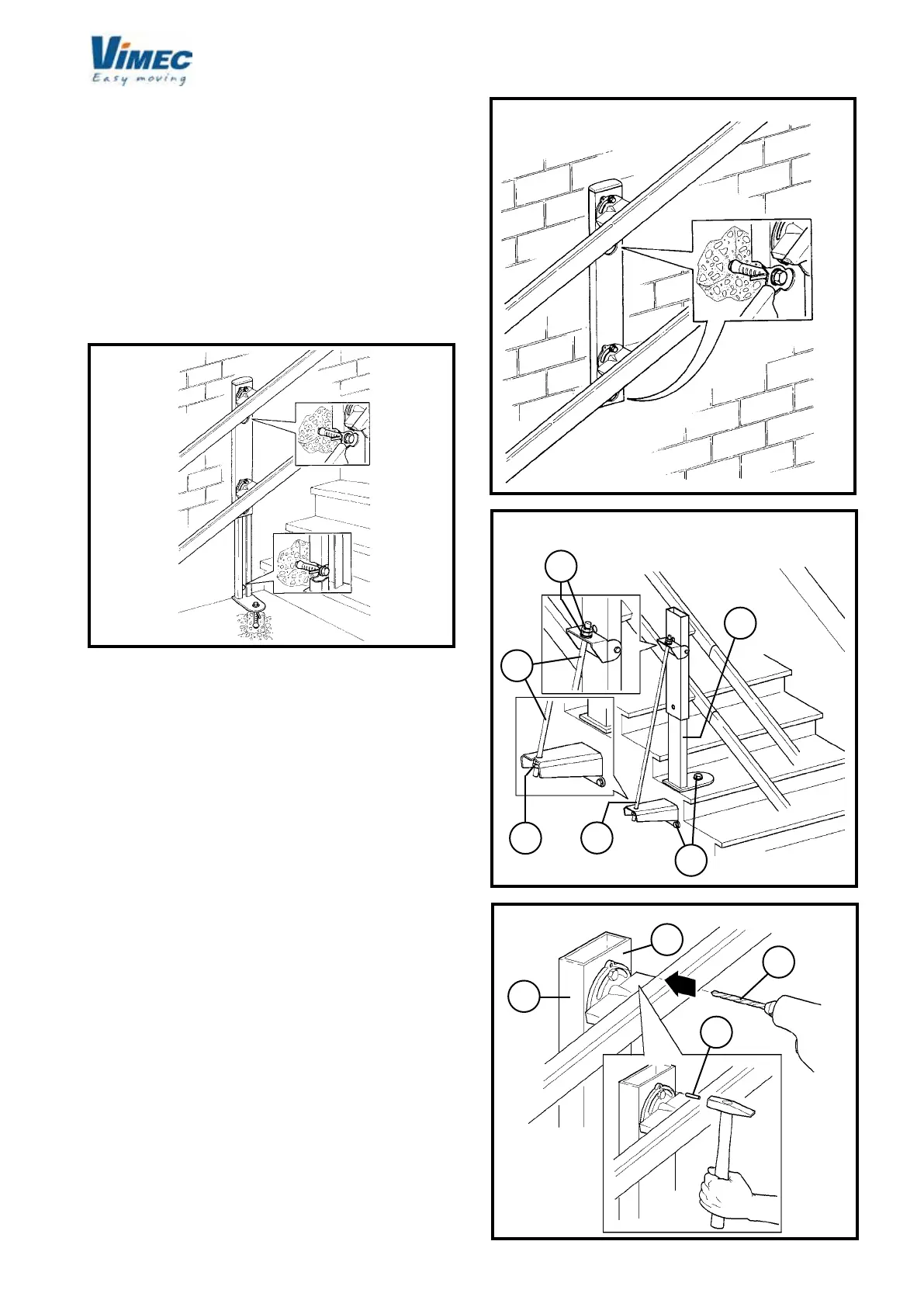

8) FIXING THE CONNECTION FEET

After performing a stairlift trial run to make sure that

everything has been assembled correctly, the next step

is to x the mounting feet to the oor and the connec-

tions to the wall (where possible, in the latter case).

Depending on the type of foot which appears in the

installation drawing, t the feet rmly as shown by the

examples below (Fig. 31-32-33).

If the feet are xed to the step (Fig. 34), drill the holes in

the steps and x using the screws (Fig. 34/a) supplied.

After the xing operation, tighten the screws hard (Fig.

34/b).

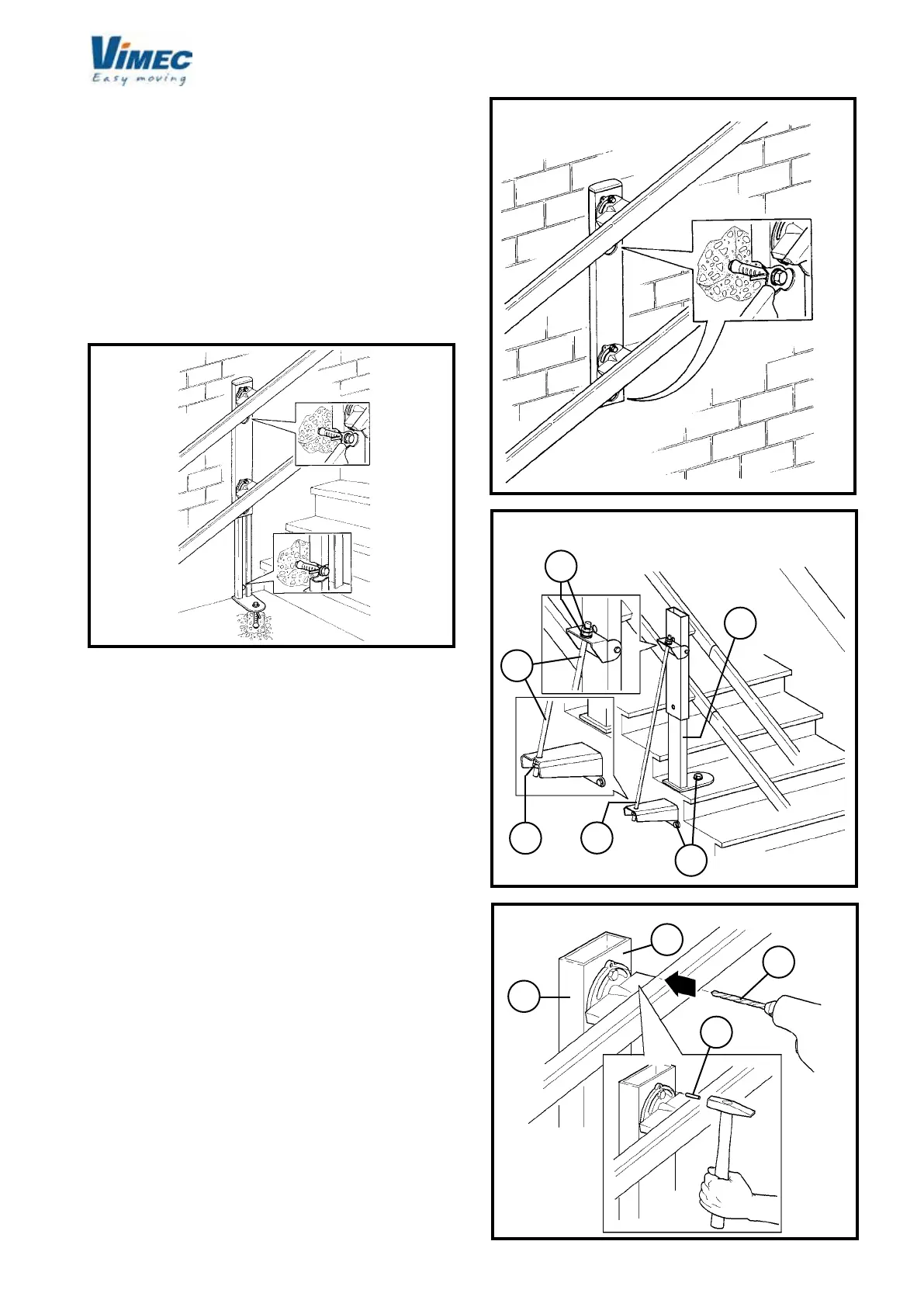

If the feet have a hinged support (Fig. 33), drill the

holes in the xing points and x using the screws (Fig.

33/a) supplied.

Tighten the foot (Fig. 33/c) by tting the threaded bar

into the holes provided (Fig. 33/b) and screwing down

the nut and lock-nut (Fig. 33/d) until the tension is

correct.

To ensure that the angle of the rail (Fig. 35/a) does not

change over time, check again that all parts have been

assembled correctly and then drill a hole (Fig. 35/b) in

the connecting joint (Fig. 35/c) and t a locking pin (Fig.

35/d) into the hole.

FIG.32

FIG.33

FIG.35

N.B.: Move the stairlift up to the 1st rigid connection and

if it is not horizontal, screw down the M10x30 screw

(Fig. 15/a) with washer (Fig. 15/b) onto the clutch

assembly to release the upper tilting device from the

clutch assembly. The gap is correct when the clutch

assembly cam is about 2 mm from the carriage (Fig.

15/c).

- Move the stairlift up a short way to allow it to settle

back into position.

- Undo the screw (Fig. 15/a) and its washer (Fig. 15/b)

to re-engage the clutch plate assembly with the tilting

device.

FIG.31

Loading...

Loading...