EN | 2928 | EN

Danger to life from CO

2

bottle pressure! In the case of improper

handling, the pressure on the CO

2

bottle can lead to serious or even fatal

injuries. Before replacing the CO

2

bottle:

• Establish a pressureless state.

Also discharge residual energy.

• Always ensure that the unintended

escape of CO

2

is prevented.

• Have defective parts to which

pressure would be applied during

normal operation immediately

replaced by a trained person.

• Always secure CO

2

bottles in an

upright position and secure against

falling.

• Always observe the safety notes on

the CO

2

bottle.

Replacing the CO

2

gas bottle

Safety instructions for using CO

2

gas cylinders.

Not following these instructions may lead to serious or fatal injuries!

Always connect the CO

2

cylinder to

the regulator. Never connect the cylin-

der directly to the carbonator to avoid

the danger of bursting. Never unscrew

ttings from containers. Always keep

the cylinder away from heat.

Only connect the CO

2

cylinder if:

• The gas cylinder location is suf-

ciently ventilated or a CO

2

warning

device is installed. Always ventilate

the area after CO

2

leakage!

• The CO

2

gas cylinder B is in an up-

right position, secured well with the

safety strap and located at a safe

distance (minimum 20 in) from any

heat sources.

• it is proved that there is no liquid gas

escape.

• The suitable pressure regulator C

with safety valve D for the dispenser

is available.

• the safety valve is sealed and fully

functional.

Danger! CO

2

is a colourless,

odourless gas. Danger of

suffocation.

• Observe the operating instructions

for handling CO

2

compressed gas

cylinders.

• Ensure that the CO

2

bottle size cal-

culated from the spatial volume of

the installation room is not exceed-

ed. Contact customer service in the

case of questions about the size of

the CO

2

bottle

• In the case of a suspected increase

in CO

2

concentrations, do not

inhale, exit the danger area and

sufciently ventilate the place of

installation.

• Dissipate the CO

2

in accordance

with the corresponding statutory

provisions.

• Always run hoses so that they

cannot come into contact with heat

sources, moisture, oil, sharp ob-

jects, sharp edges etc. Do not bend

or pinch hoses.

• Do not touch a frozen CO

2

bottle.

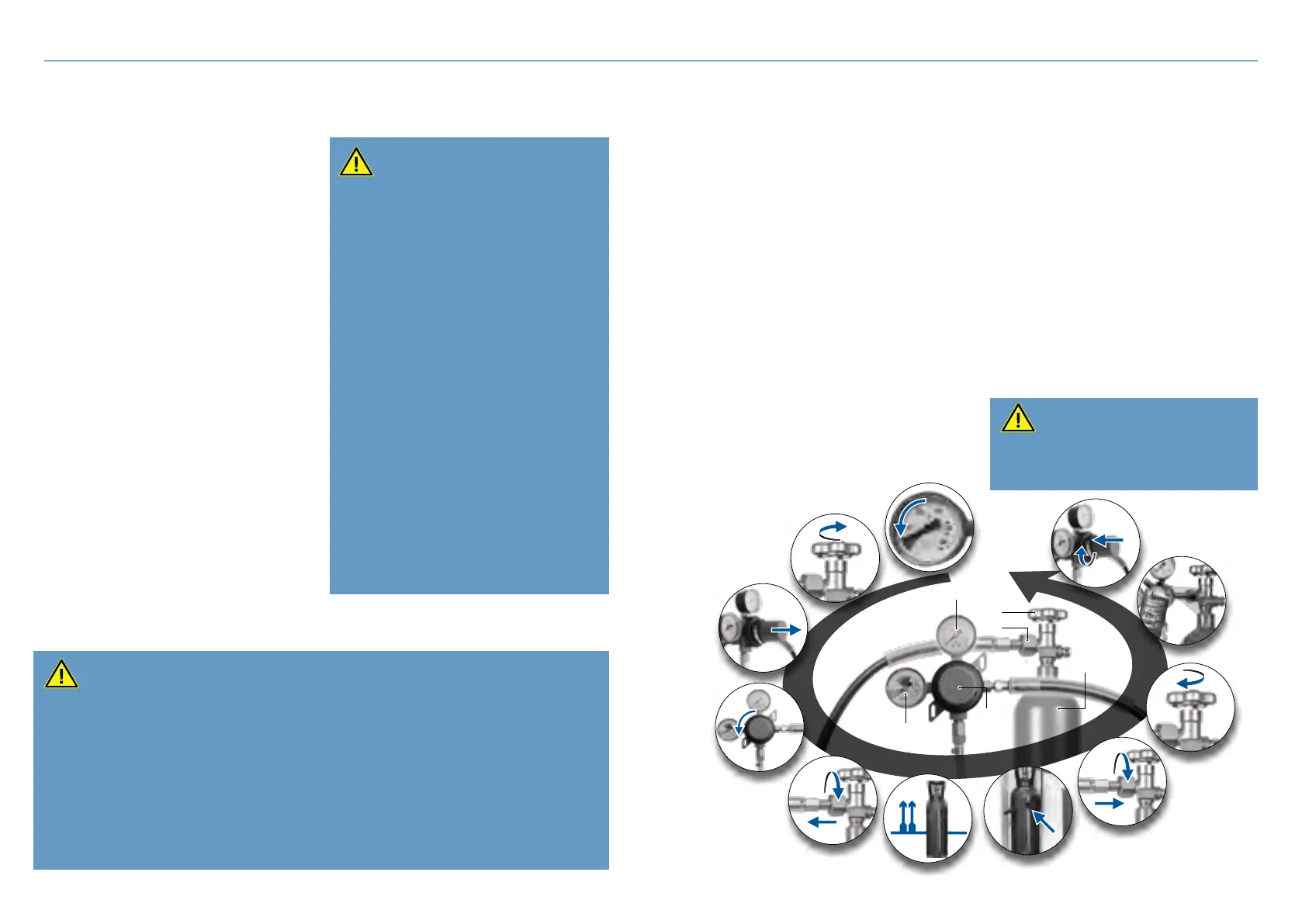

11 steps to change the CO

2

cylinder safely:

1. CO

2

bottle is empty.

2. Close the CO

2

bottle valve F.

3. Pull the cap C up.

4. Turn knob (counterclockwise) as

far as it will go.

5. Remove the hose from the empty

cylinder E.

6. Remove cyclinder D. Secure it

upright.

7. Secure the new cylinder upright

with safety strap. Remove dust

cap from new cylinder.

8. With cylinder valve F in closed

position, reattach regulator to

cylinder E. Taprite regulators have

an inlet nipple seal (O-ring) that

eliminates the need for a washer.

Tighten nut with wrench. Ensure

all connections are tightened. Do

not overtighten.

9. Open CO

2

bottle valve F all the

way. Check gauge A. The dis-

played pressure gauge should

stay stable when you close valve

again.

10. Check for leakage with solution

of soapy water or an equivalent.

Appearing bubbles are a sign of

leakage. If leakage problem can

not be solved, contact customer

service (see back page).

11. Open the CO

2

bottle valve F. Turn

cap knob (clockwise) until 65 PSI

is reached and then press down

on the cap to lock in place.

WARNING!

Increasing the pressure

above 65 PSI can cause damage

resulting in leaks and/or system

failure.

D

E

F

4.

5.

1.

3.

2.

6.

7.

8.

9.

10.

11.

Loading...

Loading...