31

Preventive Maintenance

To achieve maximum operating safety and service life, it is vital to maintain the en-

gine and its fittings in accordance with the maintenance schedule. This gives instruc-

tions on when and how to carry out maintenance. Always consult an authorized Volvo

Penta service dealer, who will have the equipment and trained staff to help you.

For boats used for commercial purposes, there is also a program of preventive main-

tenance known as “Condition Test”, which is part of the “Cost Control Program”. This

program is carried out every 6 months, and every other time in accordance with an

extended program.

A maintenance program well carried out gives better operating economy and fewer

unplanned periods of non-operation.

Engine, oil change intervals

Dependent on the fuel’s sulfur content and the quality of the lubricating oil.

However, the oil should always be changed at least once a year even if the operat-

ing times in the table are not achieved.

Engine Oil quality Fuel sulfur content, % by weight

<0.5 0.5–1.0

Hours Hours

TAMD71 VDS* 500 250

TAMD63 and TAMD72 VDS* 200 100

TAMD71 API: CD or CE 250 125

TAMD63 and TAMD72 API: CD or CE 100 50

*VDS = “Volvo Drain Specification”

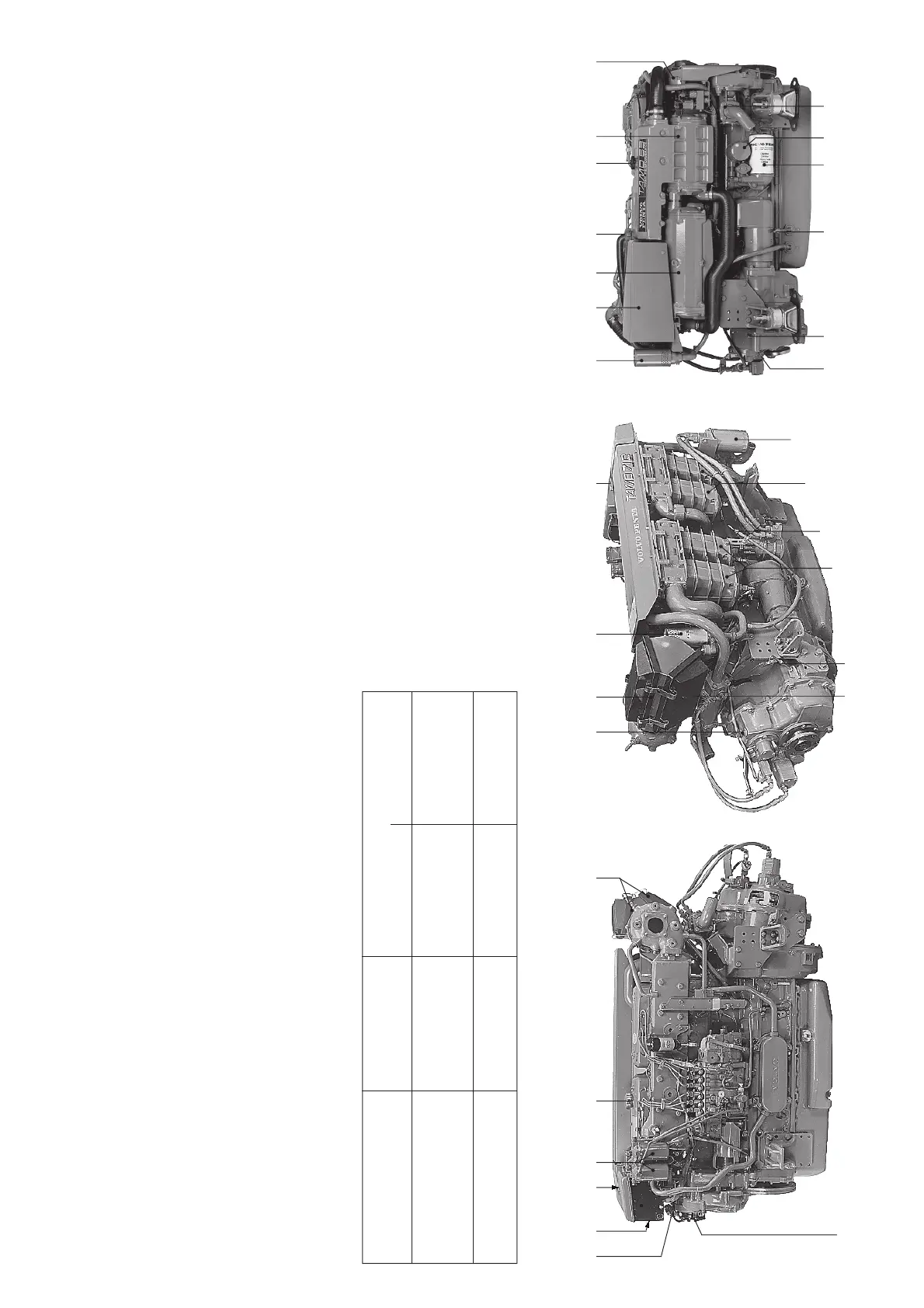

A.* Engine lubricating oil. Filler cap.

B. Terminal box with semi-automatic fuses.

Push the button if a fuse has tripped.

C. Coolant. Cap for checking and topping up

D. Fine fuel filters.

E. Air Cleaner (ACL)

F. Generator (GEN)

G. Lubricating oil, reverse gear. Cap for fill-

ing.

H. Filter for crankcase ventilation.

*Also at front of engine TAMD71 in commer-

cial boats and auxiliary engines (accessory).

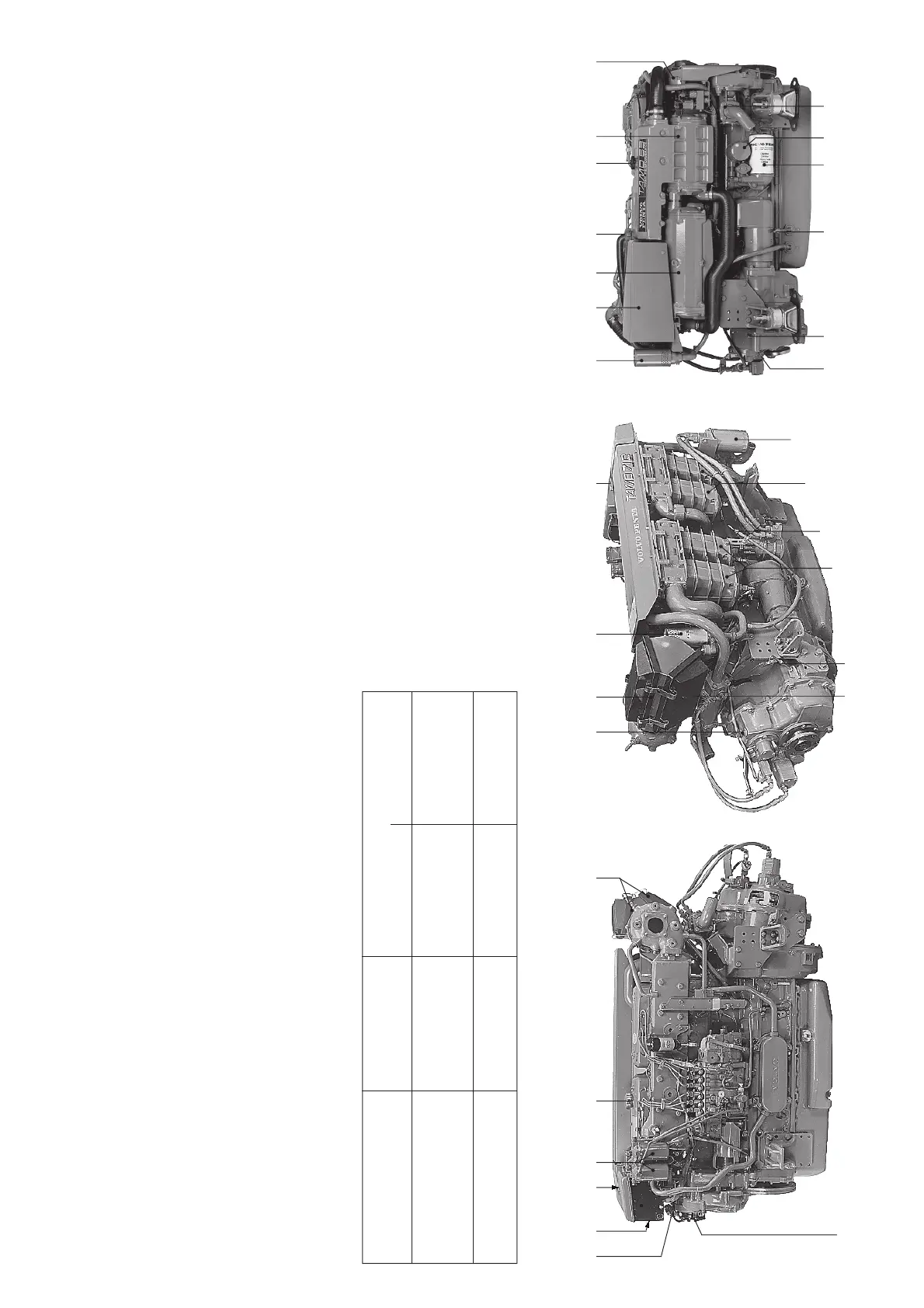

I. Lubricating oil filter, engine (alt. locat. rear of

engine’s left side).

K. Heat exchanger(s).

L. Oil dipstick, engine.

M. Charge air cooler(s) (CAC).

N. Oil dipstick, reverse gear (alt. location on left

or right side, depending on type of reverse

gear).

O. Seawater pump.

P. By-pass filter for lubricating oil.

HEMA CK F

NG L IPO

GE H C

EN

I

L

K

M

A

*

BCD A E

F

Loading...

Loading...