52

Technical description

Cooling system

These engines are fluid-cooled and have a closed circuit cooling system. The system has two circuits. In the in-

ner circuit (the freshwater system), coolant is pumped around by a centrifugal-type coolant pump (circulation

pump). In the TAMD63, this pump is driven by the vibration damper via a belt. In other engines, the coolant

pump is gear-wheel driven via the timing gears.

From the coolant pump, the coolant is pumped out into a distribution channel in the cylinder block and con-

veyed around the cylinder liners and on up through the cylinder heads.

From each cylinder head and from the turbocharger’s turbine housing, the coolant is fed back to the thermostat

housing, where a thermostat regulates the coolant temperature. Coolant from the engine’s oil cooler is also fed

to the thermostat housing.

While the coolant is cold, the thermostat shuts off the flow to the heat exchanger. The coolant then passes

through a by-pass line beneath the thermostat and directly back to the pump’s suction side. When the coolant

temperature has risen to a certain value, the thermostat opens and allows coolant to pass to the heat exchang-

er and the by-pass line closes.

In the heat exchanger, heat from the coolant is transferred to the seawater before the coolant is sucked back

into the coolant pump.

Large amounts of heat are also removed by the lubricating oil, which channels off the heat to the freshwater

system via the oil cooler. The lubricating oil is also used to dissipate heat from the pistons in the engine (see

“Pistons” on page 39).

The cooling system may operate with a small amount of overpressure. The risk of boiling is thereby reduced if

the temperature is high. If the pressure is higher than normal, a pressure valve in the filler cap opens.

The flow in the seawater system is maintained by a gear-wheel driven impeller (blade-type) pump which is lo-

cated at the front of the engine. The seawater passes through the engine’s heat exchanger(s)* and charge air

cooler(s) and the reverse gear’s oil cooler. A zinc anode is fitted in the reverse gear’s oil cooler as protection

against galvanic corrosion. The TAMD63 also has a zinc anode in the heat exchanger and the charge air cooler

(CAC).

It is important to check the condition of the zinc anode(s) according to the maintenance schedule to prevent cor-

rosion damage.

The engine may have a separate expansion tank as an accessory.

*In the TAMD63, the seawater passes the charge air cooler before being fed to the heat exchanger and the reverse gear’s oil

cooler.

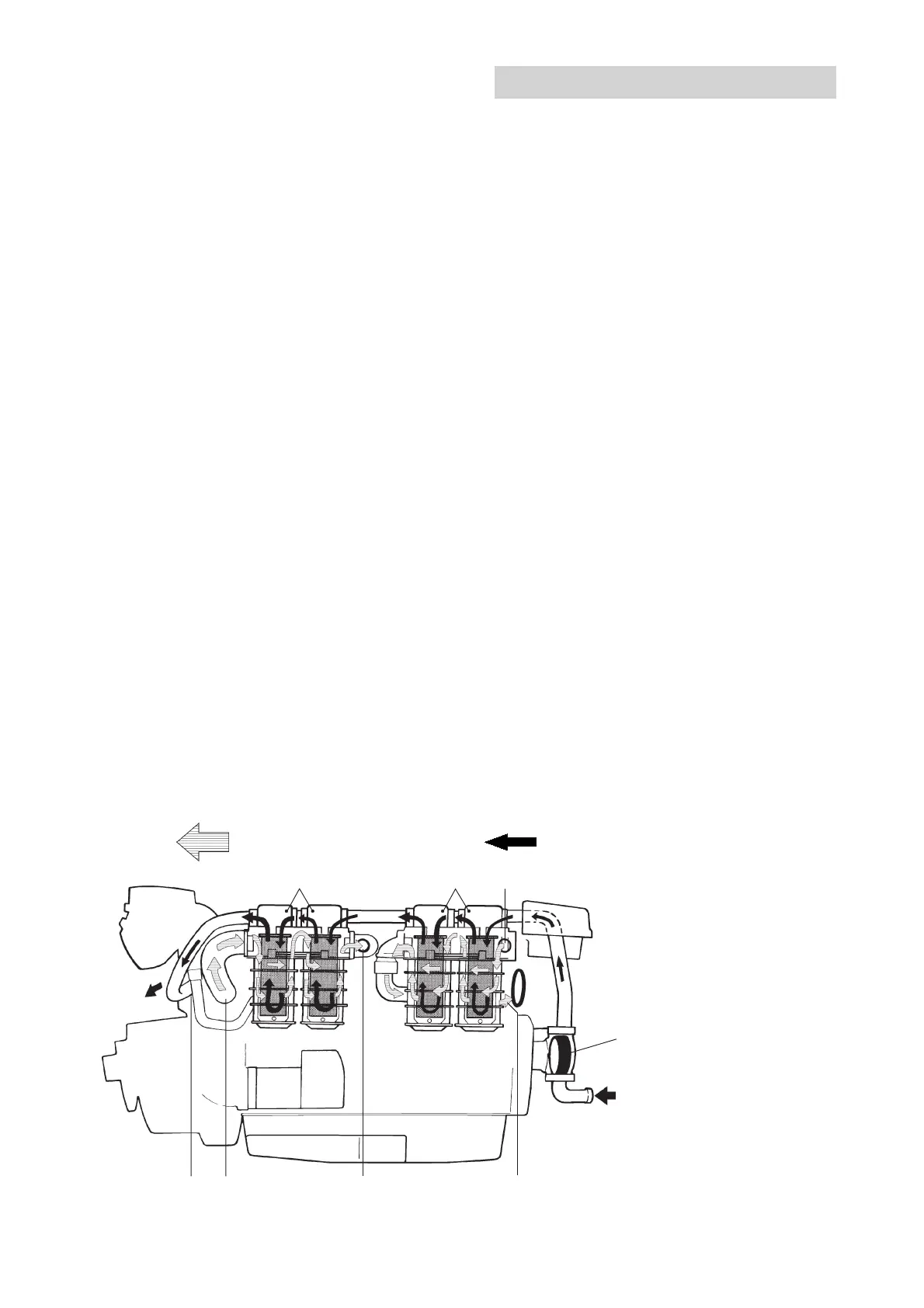

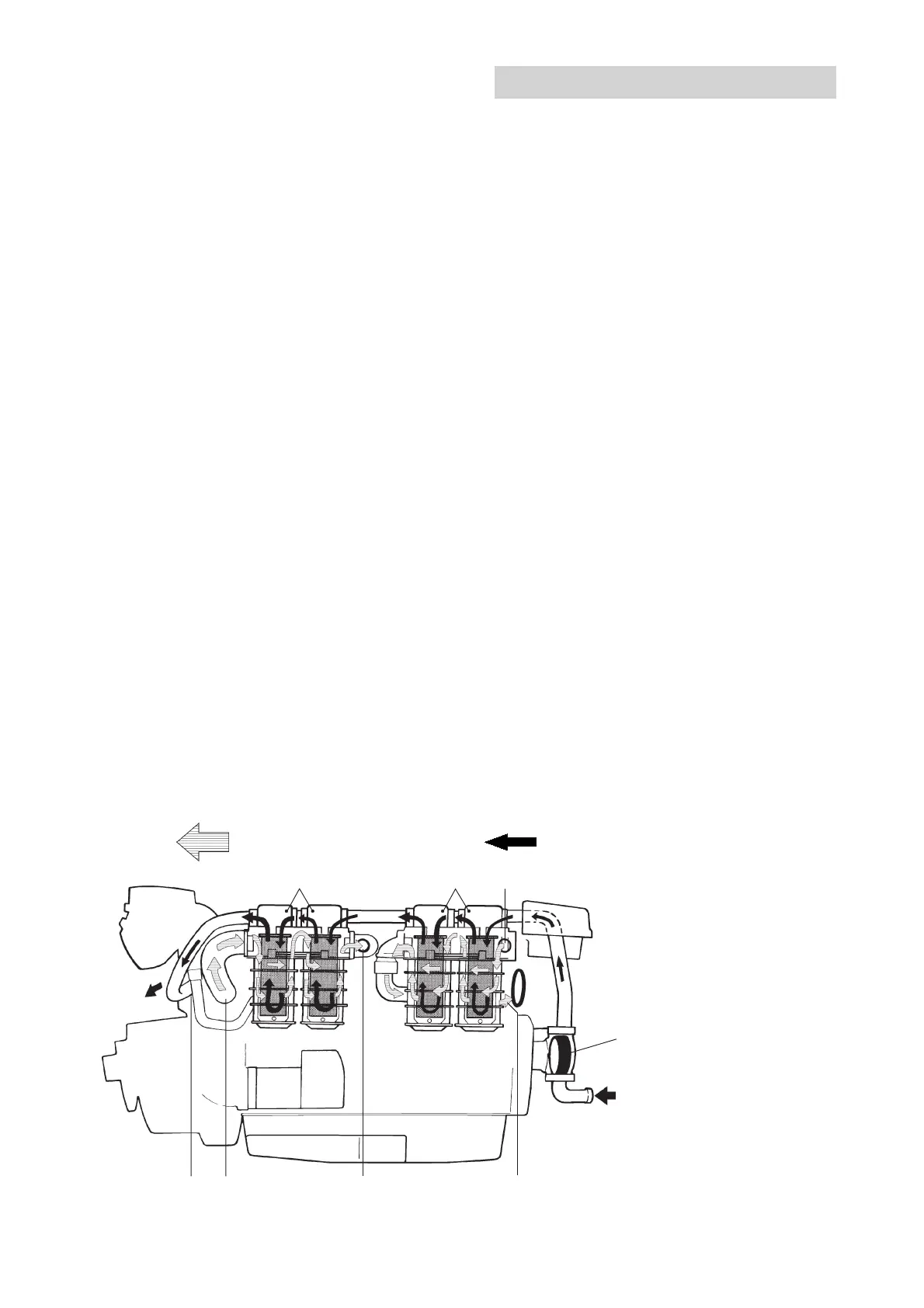

Flow through heat exchanger and charge air cooler (CAC) in the TAMD71, -72

= Charge air or freshwater = Seawater

1. Seawater inlet

2. Seawater pump

3. Freshwater from en-

gine thermostat hous-

ing

4. Heat exchangers

5. Charge Air Coolers

(CAC)

6. Sea water outlet

7. Oil cooler, reverse

gear

8. Charge air from turbo-

charger

9. Cooled charge air to

the engine intake man-

ifold

10. Freshwater to the en-

gine coolant pump,

suction side

78 9 10

543

6

2

1

Loading...

Loading...