30

e must be st

er. Release the catch (A)

ockford/BW), or clockwise (A.P.). Lock

not slip after engagement.

Screw on the new filter by hand. Note. Change filter earlier if air and oil

mixture has begun to press out past the valve (1). Check the drain hose (2)

is not clogged.

TAMD63 MD71, TAMD72

0. Check/adjust disengage-

able clutch (if fitted).

11. Replace filter for

crankcase ventilation.

1) TAMD63 and TAMD72.

2) TAMD71.

1. Engine oil change

Note: See table above for ratio of oil

quality to replacement interval.

1) TAMD63 and TAMD72.

2) TAMD71.

2. Replace oil filter (1) and

by-pass filter if fitted (2)

at every other oil

ch

50 Hrs

100 Hrs

250 Hrs

500 Hrs

1000 Hrs

2000 Hrs

23

23

23

23

23

23

23

23

23

45

45

41

●

1)

●

2)

●*

●

1)

●

2)

VDS engine oil or CD or CE as per API system. Drain or pump out oil while

engine is hot.

WARNING! Hot oil can cause burns.

Lubricate gasket and screw on new filter by hand. Tighten by 3/4 turn once

gasket is tight. Top up oil, start, check for leaks. Stop engine and check oil

level.

* Note: Special recommendations apply for new or reconditioned

engines. See instructions. “Running-in” on page 4.

No. Action Instructions Info.

pge.

Rockford/ BW A. P.

Maintenance

Periodic maintenance

If your engine and its fittings are to function reliably, periodic maintenance in accordance with the maintenance

schedule is required. Several of the items deal with the replacement of consumables such as oil filters, fuel fil-

ters, etc.

To ensure continued trouble-free use of your engine, it is important always to use original spares. Always state

the type designation and serial number of your engine and its fittings when ordering parts.

Some operations require professional experience and special tools. Therefore, get authorized service person-

nel to carry out more extensive work.

For further information, see under the heading “Maintenance” in accordance with the respective section in

“Technical Description”.

New engine with reverse gear

See instructions “Running-in” on page 4.

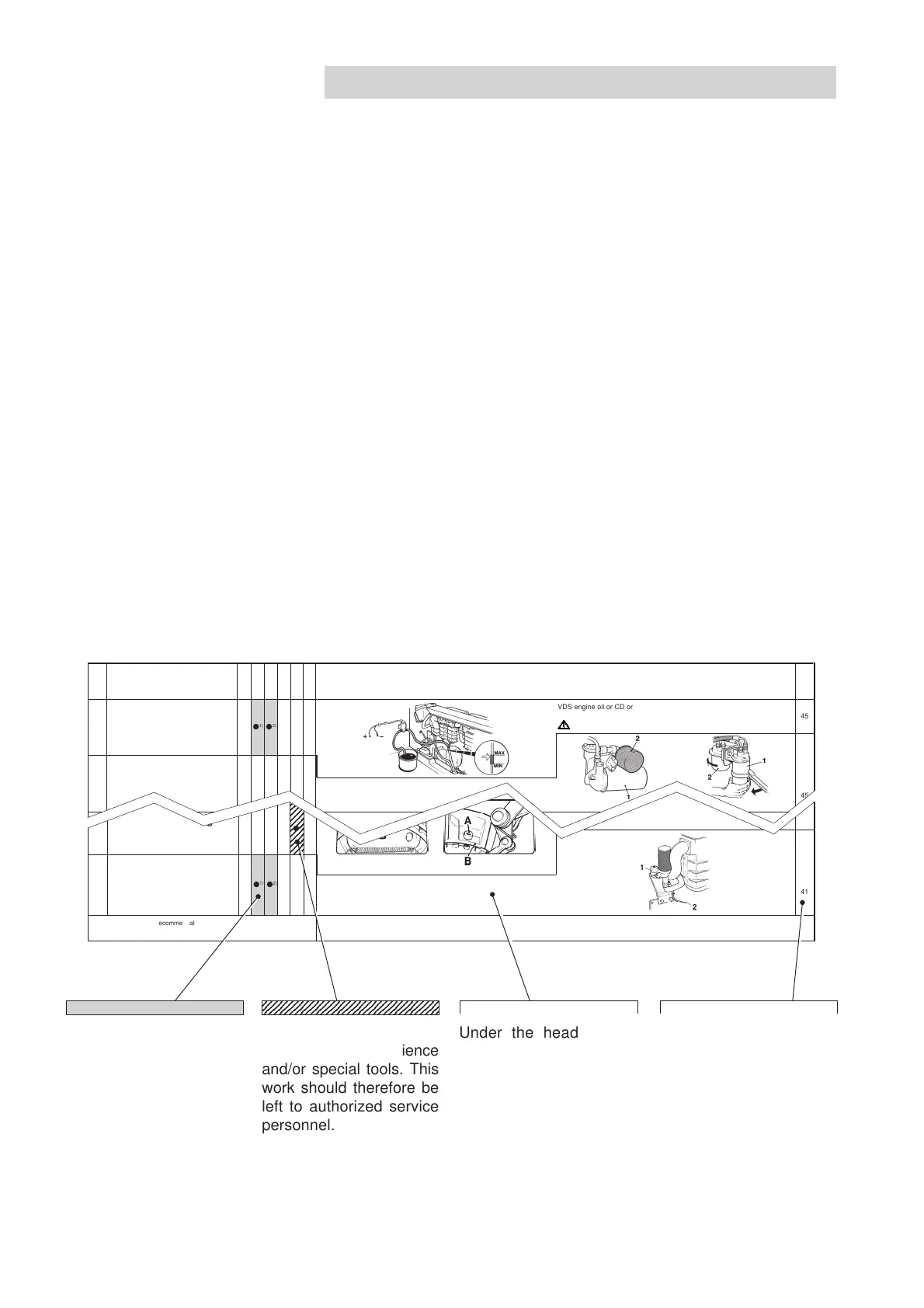

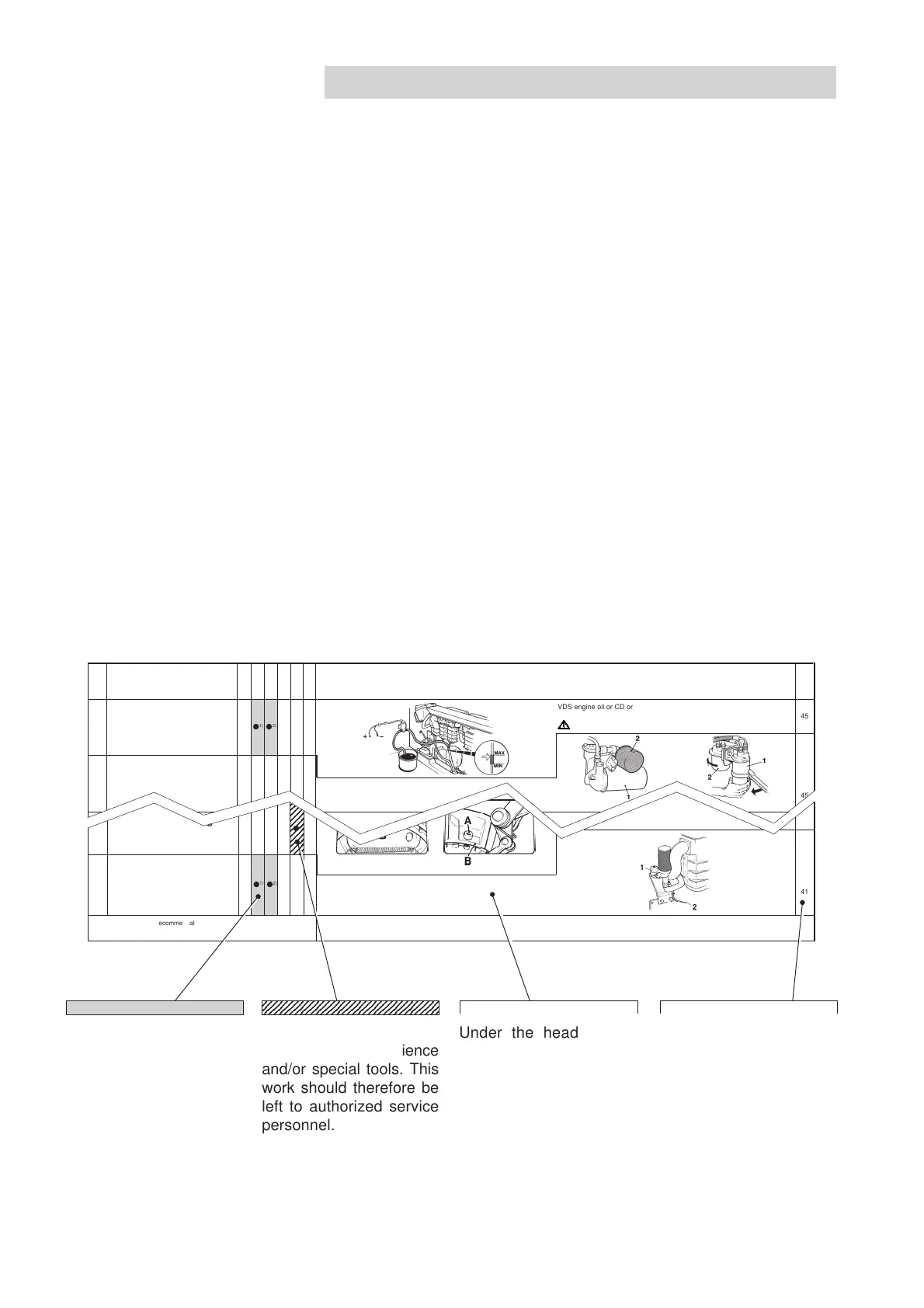

Layout of the maintenance schedule

Shading denotes simpler

operations which can be

carried out by the boat

owner himself.

12345678901234567890123456789012123

1

234567890123456789012345678901212

3

12345678901234567890123456789012123

Lines indicate operations

which require experience

and/or special tools. This

work should therefore be

left to authorized service

personnel.

Under the heading “In-

structions” is a brief sum-

mary of what should be

rectified when carrying out

the maintenance job in

question.

Under the heading “Infor-

mation page” are refer-

ences to the information

pages towards the back of

the manual. In most cas-

es, these pages provide a

more detailed description

of the operations required.

Loading...

Loading...