C23i Maintenance Instructions

Lubrication

55

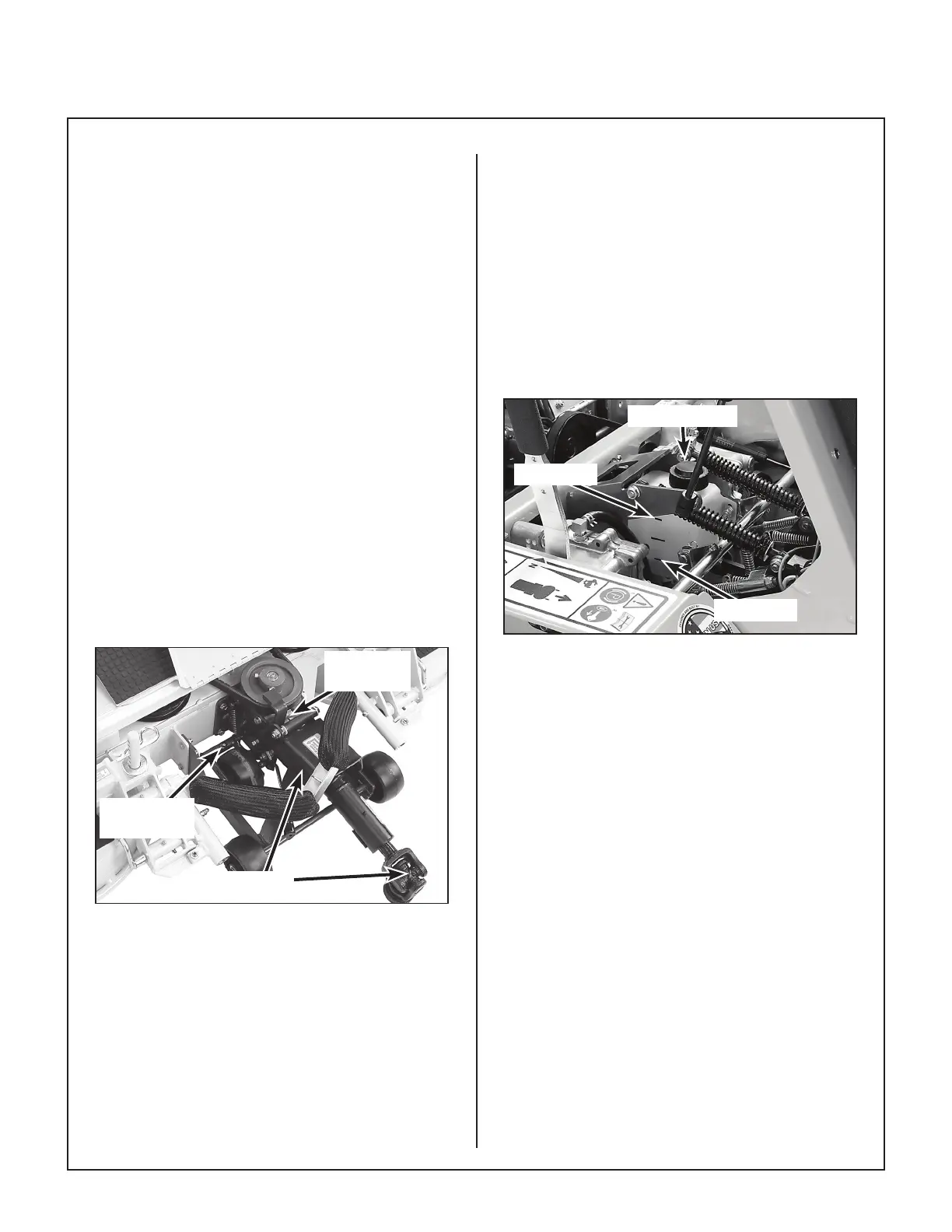

DS52 Mower Deck Lubrication

There are several special lubrication requirements

for the DS52 mower deck in addition to the require-

ments detailed in the Chassis and Deck Lubrica-

tion Points illustration. Lubricate the locations

shown in the Gearbox, Dolly Wheel, and U-Joint

Lubrication photo and check and maintain oil in

the belt drive gearbox.

1. Check the oil level in the belt drive gearbox

ev ery 100 hours (or sooner if a visible oil leak

has developed). With the deck in the normal

oper ating position, remove the level plug in the

side of the gearcase. Add SAE E.P. (Extreme

Pres sure) 80W-90 (API GL-5) gear lube to

maintain the oil level to the plug. If the oil level

is low, check the gear box for any indication of

an oil leak. If an oil leak is noted, the gearbox

will need to be removed and rebuilt.

2. Lubricate the dolly wheel pivot every 25 hours

with general purpose grease.

3. Lubricate both drive shaft u-joints every 25

hours with SAE general purpose lithium or

molybdenum base grease.

Belt Drive

Gearbox

Dolly Wheel

Pivot

U-Joints

Gearbox, Dolly Wheel, and U-Joint Lubrication

Mower Deck Spindle Lubrication

For mower decks with belt-driven blades, lubricate

each deck spindle grease tting every 25 hours.

Use SAE general purpose lithium or molybdenum

base grease for grease ttings.

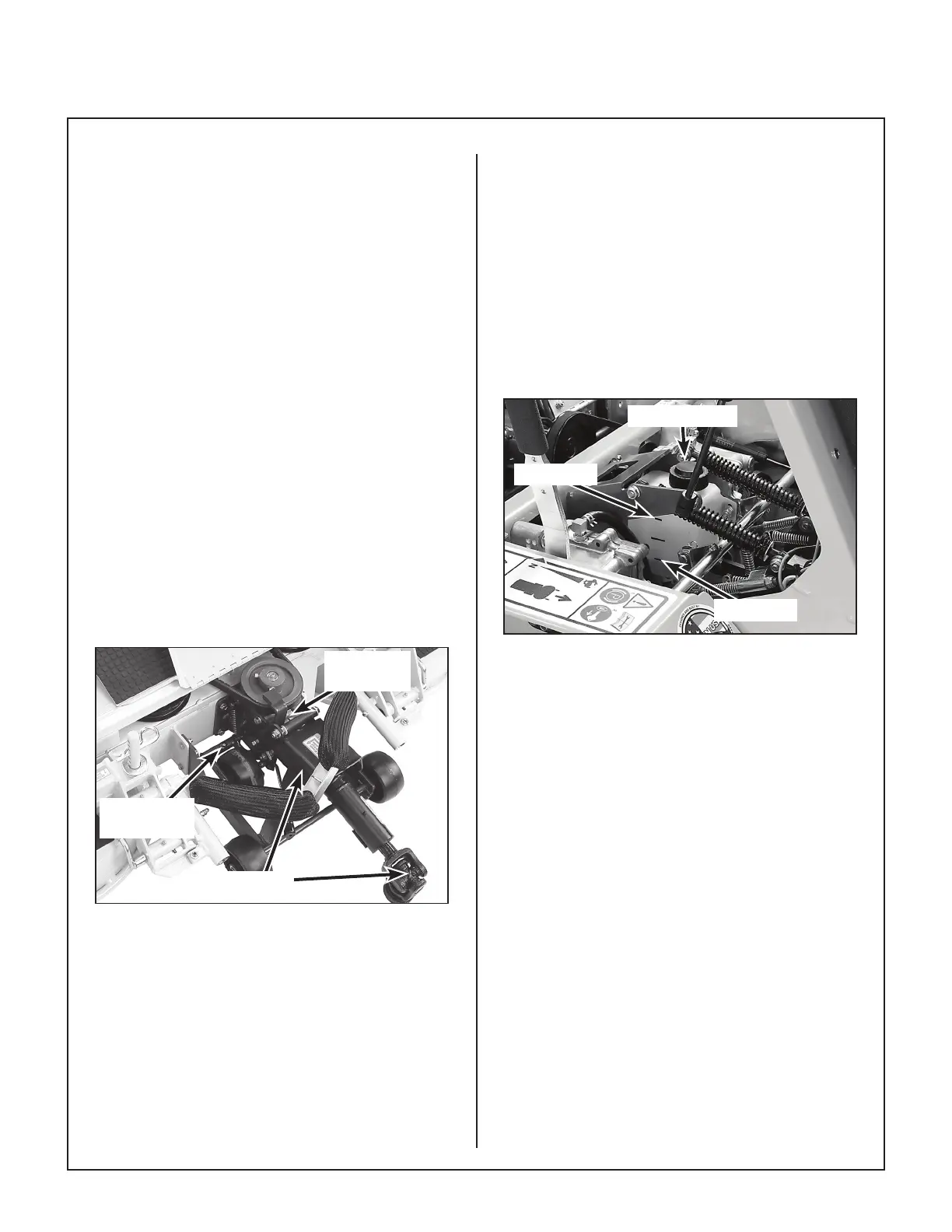

Check Transaxle Fluid Level

● The transaxle oil lubrication is SAE 20W-50

(API Service Class SL or higher) engine oil.

● Inspect both transaxle cases after every 25

hours of operation for visible leaks.

● The uid level of the transaxles can be

checked visually by looking at the uid level in

the expansion reservoir. When the transaxles

are cold, the uid level in the expansion reser-

voir should be between 1/4 in. and 1/2 in. (6-13

mm) from the bottom, near the Cold Level line.

Cold Level

Hot Level

Reservoir Cap

Expansion Reservoir Location

Grease Fitting and Oil Point Lubrication

Lubricate the grease ttings and oil points after

every 25 hours of operation. Lubricate more

often when operating in dusty or dirty condi-

tions. Use SAE general purpose lithium or molyb-

denum base grease for grease ttings and light

machine oil (SAE 10) to lubricate oil points. Lubri-

cate the locations shown in the Chassis and Deck

Lubrication Points illustration on page 57.

NOTE: PTO universal joints (on the deck and

trac tor) require routine lubrication after every 25

hours of running time. Remove tractor PTO quick

disconnect tube assembly for easy access to

grease ttings.

NOTE: The best way to lubricate the PTO tube

half of the universal joint assembly is to remove it

from the tractor. See instructions for removing and

install ing PTO quick coupler, refer to Deck Installa-

tion on page 22.

NOTE: The ball bearings on the PTO drive shaft

are sealed and do not require periodic mainte-

nance.

Loading...

Loading...