Service and Maintenance

FX85, FX110, FX140

Skidding Winch

44

• Replace any hydraulic hose immediately that shows signs

of swelling, wear, leaks or damage before it bursts.

• Do not bend or strike high-pressure lines, tubes or hoses,

or reinstall them in a bent or damaged condition.

• Check to make sure hydraulic hoses are not worn or

damaged, and are routed to avoid chafing.

• Never adjust a pressure relief valve or other pressure-

limiting device to a higher pressure than specified.

9.2 Maintenance Schedule

Perform maintenance procedures at time shown or hour interval,

whichever comes first.

As Necessary

Remove any entangled material from the machine.

Check that all fasteners are torqued to the correct torque.

Check the condition of all cables, ropes, and chains.

Check the clutch adjustment. See page 34.

Every 50 hours or weekly

Grease the PTO shaft See page 44

Examine and lubricate the chain

drive

See page 45

Check the condition of the clutch

rope.

—

Every 100 hours or Annually

Clean the machine. Remove debris

and entangled material.

—

Check the drive chain tension See page 46

Clean and lubricate the PTO shaft. —

Examine the cable or winch rope. —

9.3 Grease Points

IMPORTANT! Do not over grease a bearing. More than one

pump of grease can push grease out of the bearing seals.

Too much grease can cause the bearing seals to fail.

Look for this type of label on the machine. Each

label identifies a grease point and shows the

greasing interval in hours.

Use an SAE multi-purpose high temperature grease with

extreme pressure (EP) performance. Also acceptable is an SAE

multipurpose lithium-based grease.

• Use a clean cloth to clean each grease fitting before you

apply grease. This prevents grease and dirt from getting

inside the component.

• Use a hand-held grease gun to apply one pump of grease to

each grease point.

• If a grease fitting is damaged, replace it immediately.

• If a grease fitting does not accept grease:

a. Remove the grease fitting.

b. Clean the passageway behind the grease fitting.

c. Clean the grease fitting thoroughly or get a new grease

fitting.

d. Install the grease fitting.

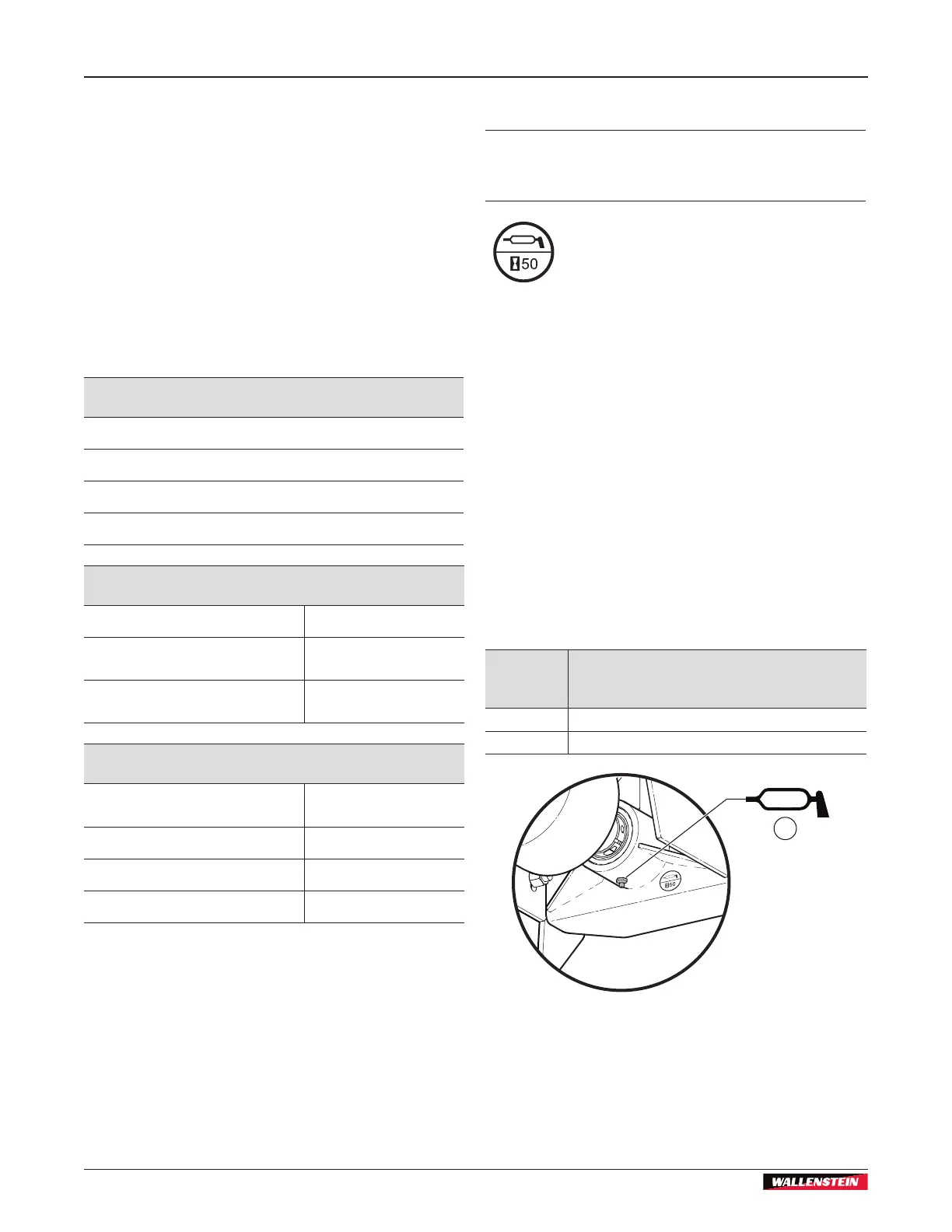

Location Grease every 50 hours of operation or weekly

1 Drive shaft, PTO shaft shield and U-joints (2 places)

2 Drive shaft slip joint

00601

1

Loading...

Loading...