FX85, FX110, FX140

Skidding Winch

Service and Maintenance

45

00519

1

1

2

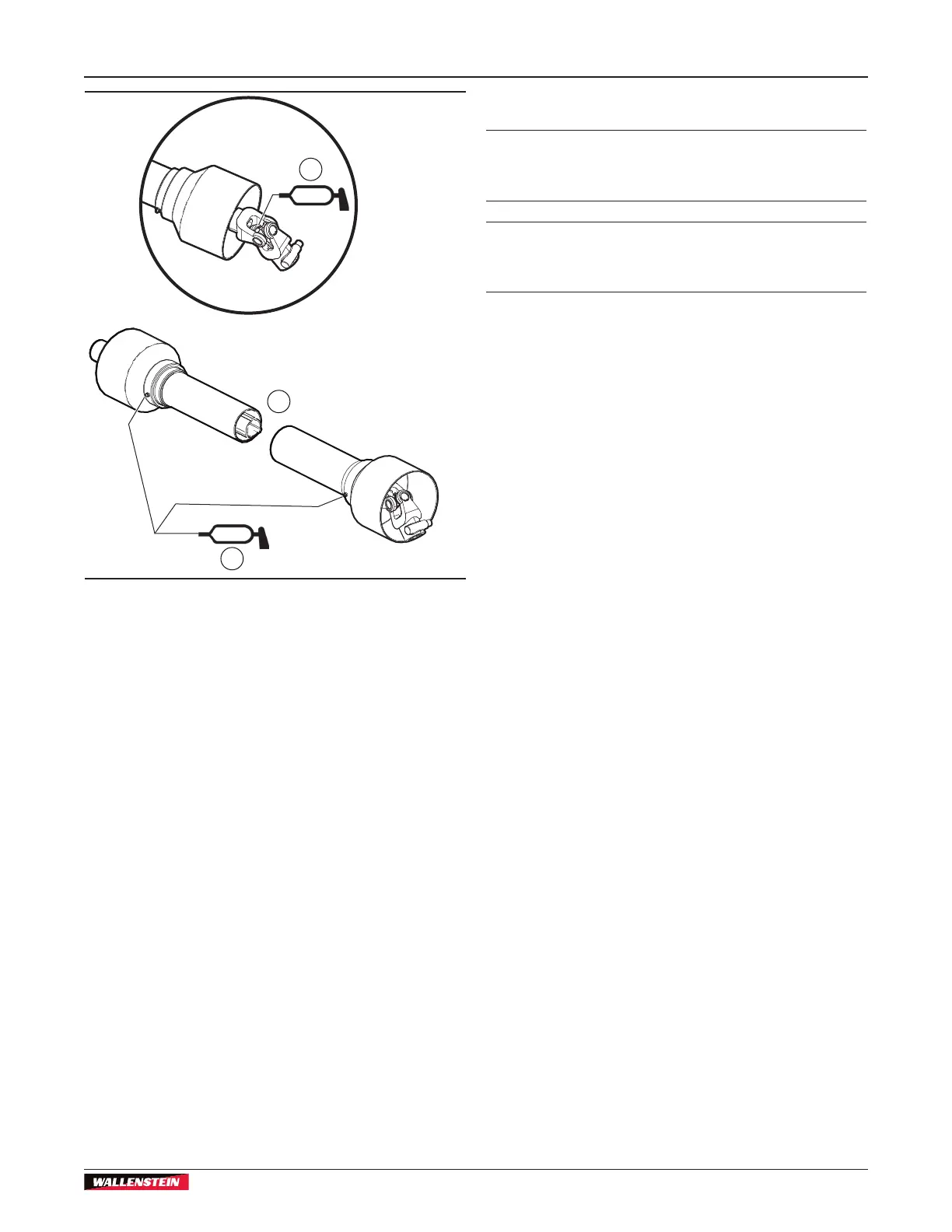

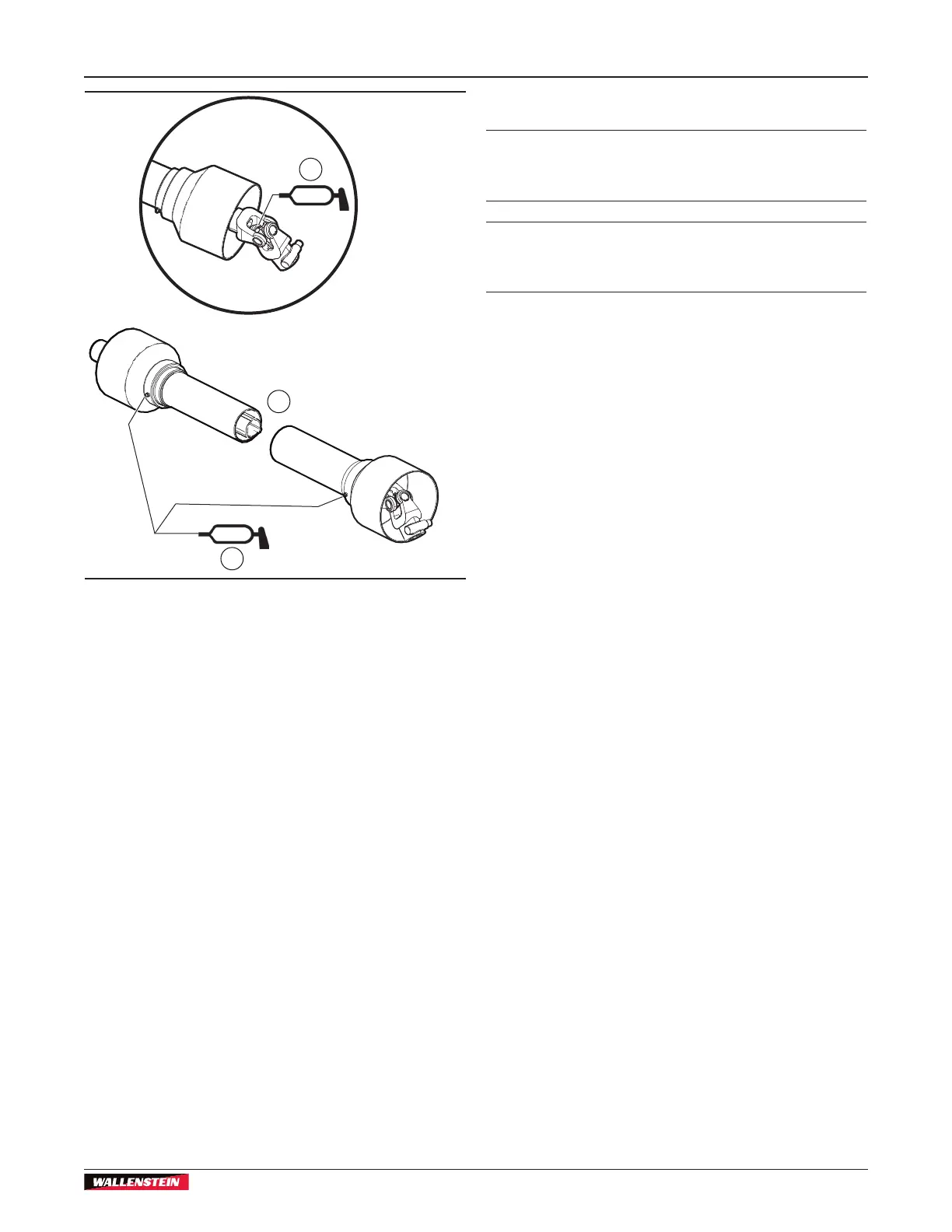

Figure 51 – Grease points

The PTO shaft is designed to telescope while the three-point

hitch goes through its operational range. A heavy duty plastic

tubular guard encloses the driving components.

The PTO shaft should telescope easily and the guard should

turn freely on the shaft at all times. Annual disassembly,

cleaning, and lubrication is recommended to make sure that all

components function correctly.

Make sure that the universal joints are lubricated, examine and

lubricate them every 50 hours.

The PTO shaft has a shear pin at the input yoke to prevent

overloading the drive system. The skidding winch is designed

to perform well without the shear pin failing. However, if the pin

fails, usually it is because the skidding winch was overloaded.

9.4 Lubricate the Drive Chain

IMPORTANT! Do not get lubricant on the clutch-brake pads.

Lubricant on the clutch-brake pads can cause the clutch to

slip.

IMPORTANT! Make sure that the lubricant reaches the

joints (pins and bushings). These components wear during

operation.

Lubricate the drive chain every 50 hours of operation.

Without the correct amount of lubrication, the drive chain can

wear excessively and fail.

For more information, see Figure 52 on page 46.

1. On the front of the machine, remove the bottom guard.

2. Spray or brush a good quality dry film lubricant onto the

drive chain and joints.

3. Install the bottom guard and fasteners.

4. Use a calibrated torque wrench to torque the fasteners to

33 lbf•ft (45 N•m).

Loading...

Loading...