9.4 Kabin Pak Installations

1. Although the Standard and Slimline Kabin Paks are manufactured from galvanised

steel, it is recommended that after a period of weathering (approx 4-8 weeks) that the

Kabin Pak is painted with a suitable primer and finish coat to prevent corrosion.

2. When using the Kabin Paks with the integral low level flue only 28 second redwood

number 1 (kerosine) may be used in order to comply with building regulations.

3. The Kabin Pak is fully insulated, although it is recommended that a frost thermostat is

fitted within the Kabin Pak unit.

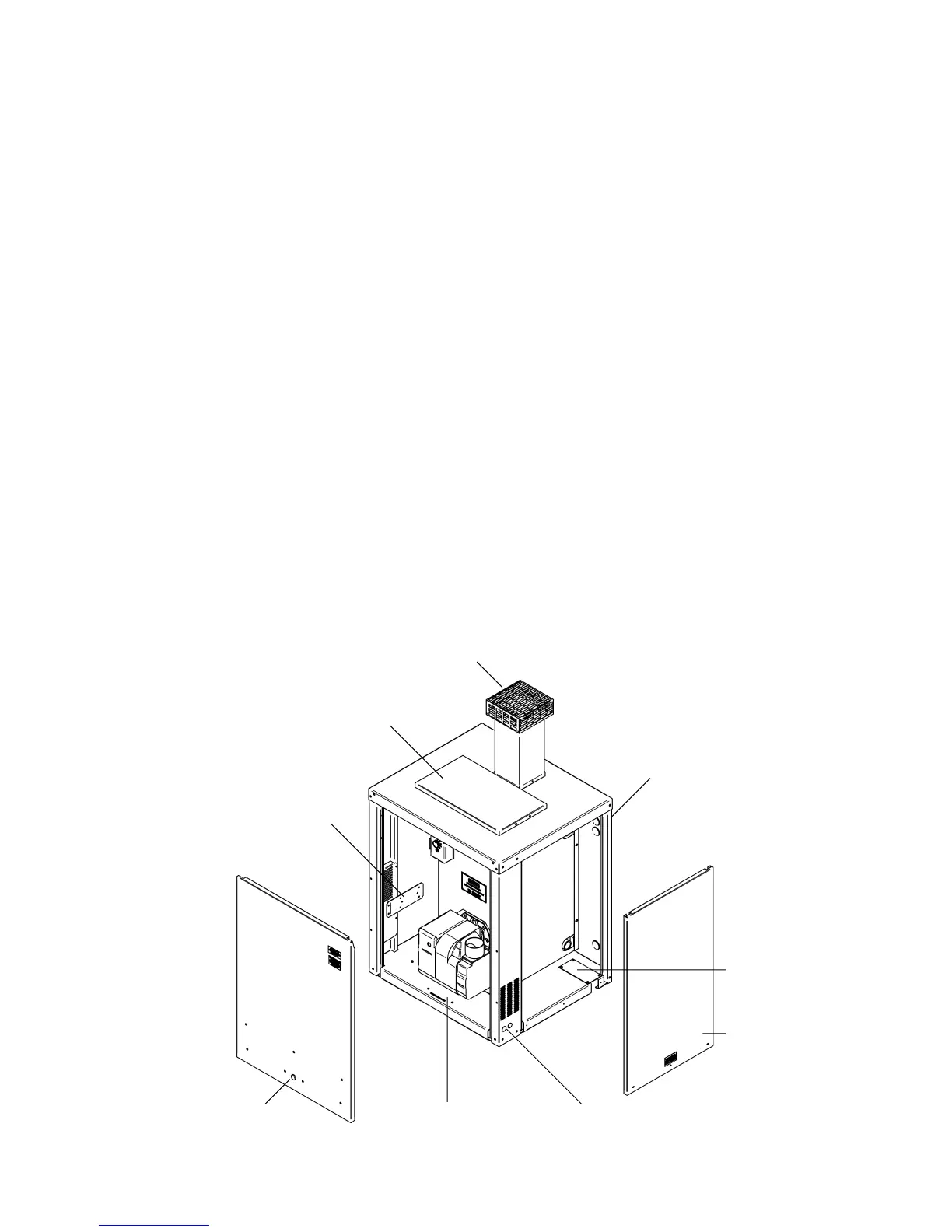

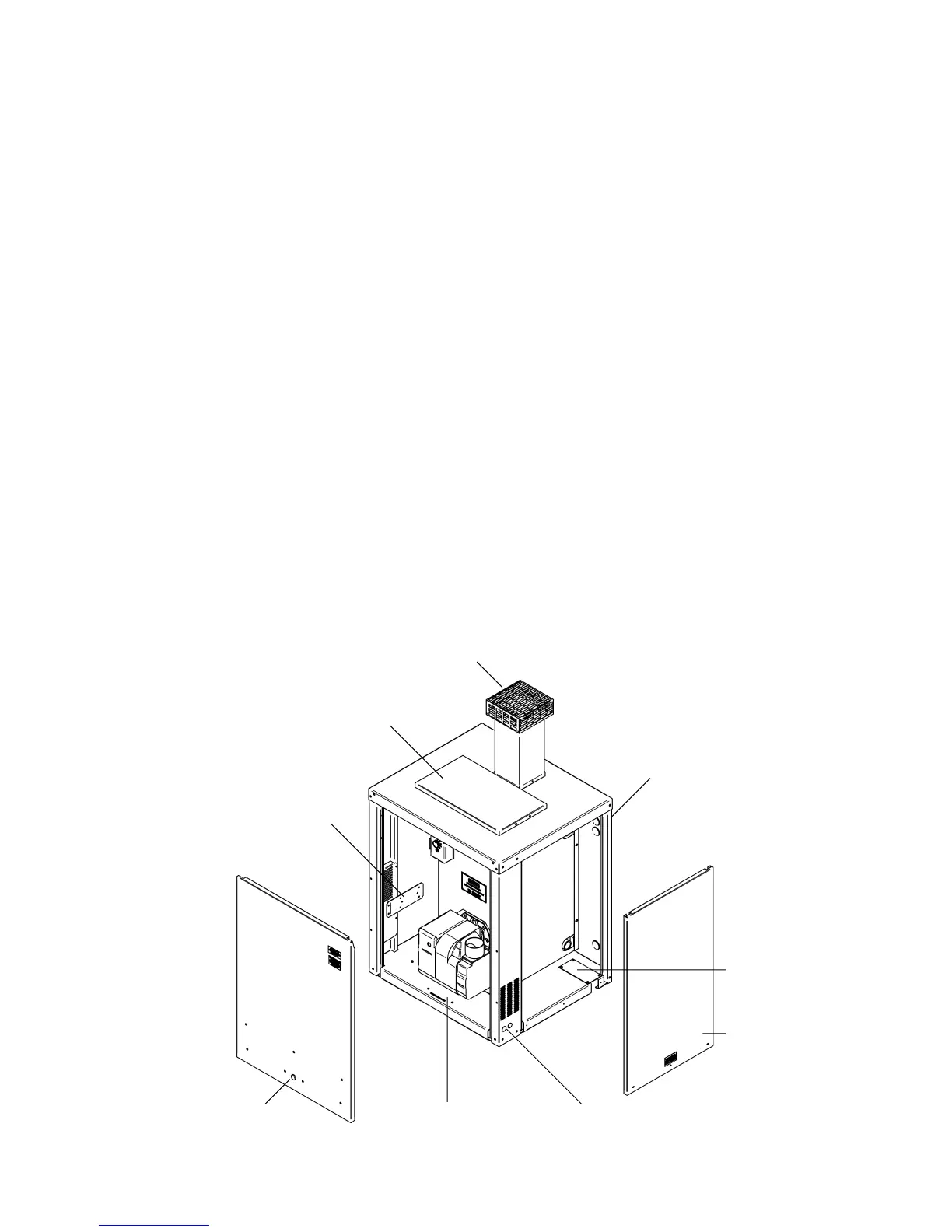

4. On the Standard Kabin Pak the two main side panels secured by 3 self tapping screws

are designed to be easily removable for access. In addition there is sufficient space

either side of the boiler to fit a circulating pump or pressure vessel as required.

5. On the Slimline Kabin Pak the rear door is easily removable (2 screws) for access and

there is sufficient space to fit a circulating pump.

6. By removing the protective basket and end cap from the integral flue an adaptor can

be fitted which allows the flue to be extended vertically using standard round twin wall

flue pipe. The vertical flue adaptor is not suitable for use with a Kabin Pak back outlet

flue.

9.5 Standard Kabin Paks

Loading...

Loading...