ENCORE

®

700 METERING PUMP

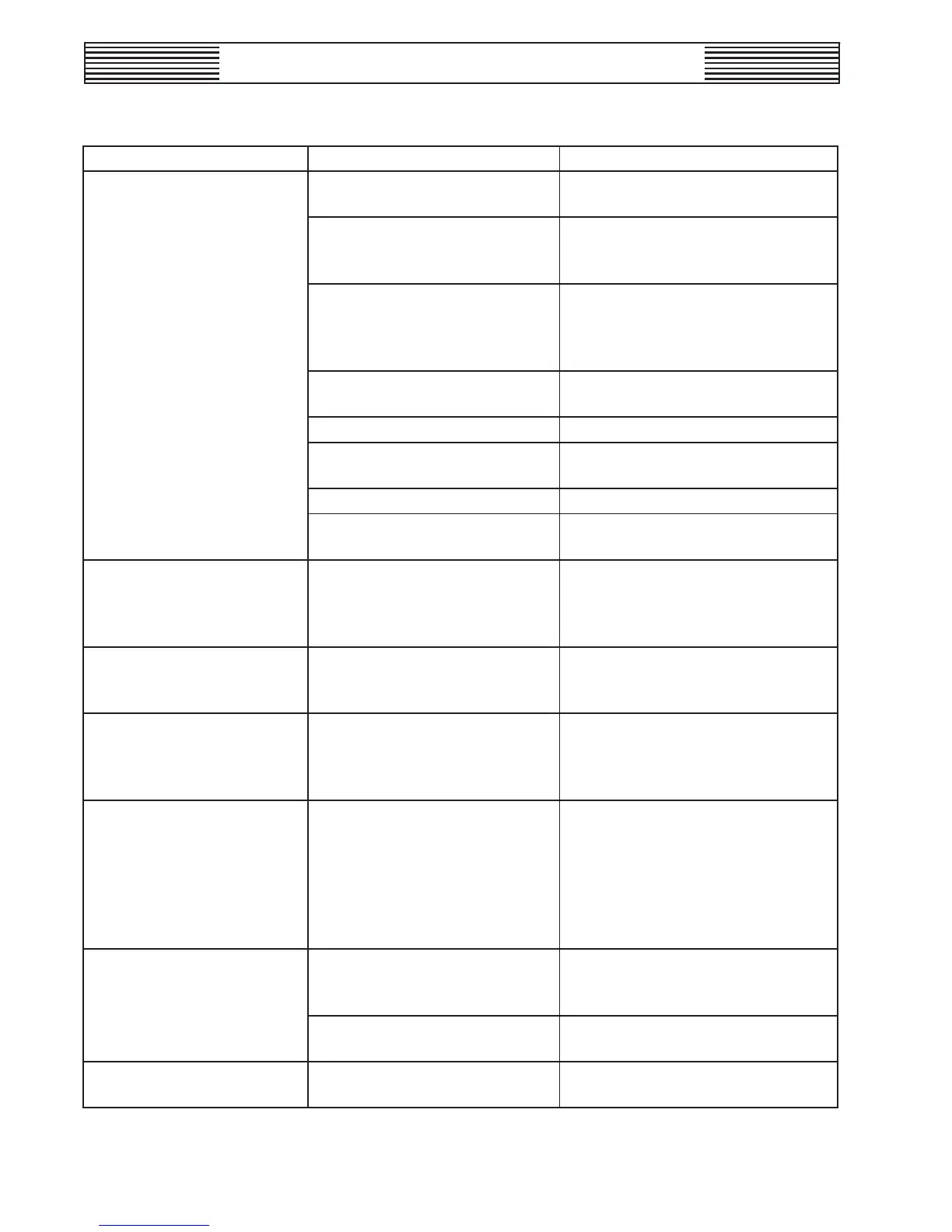

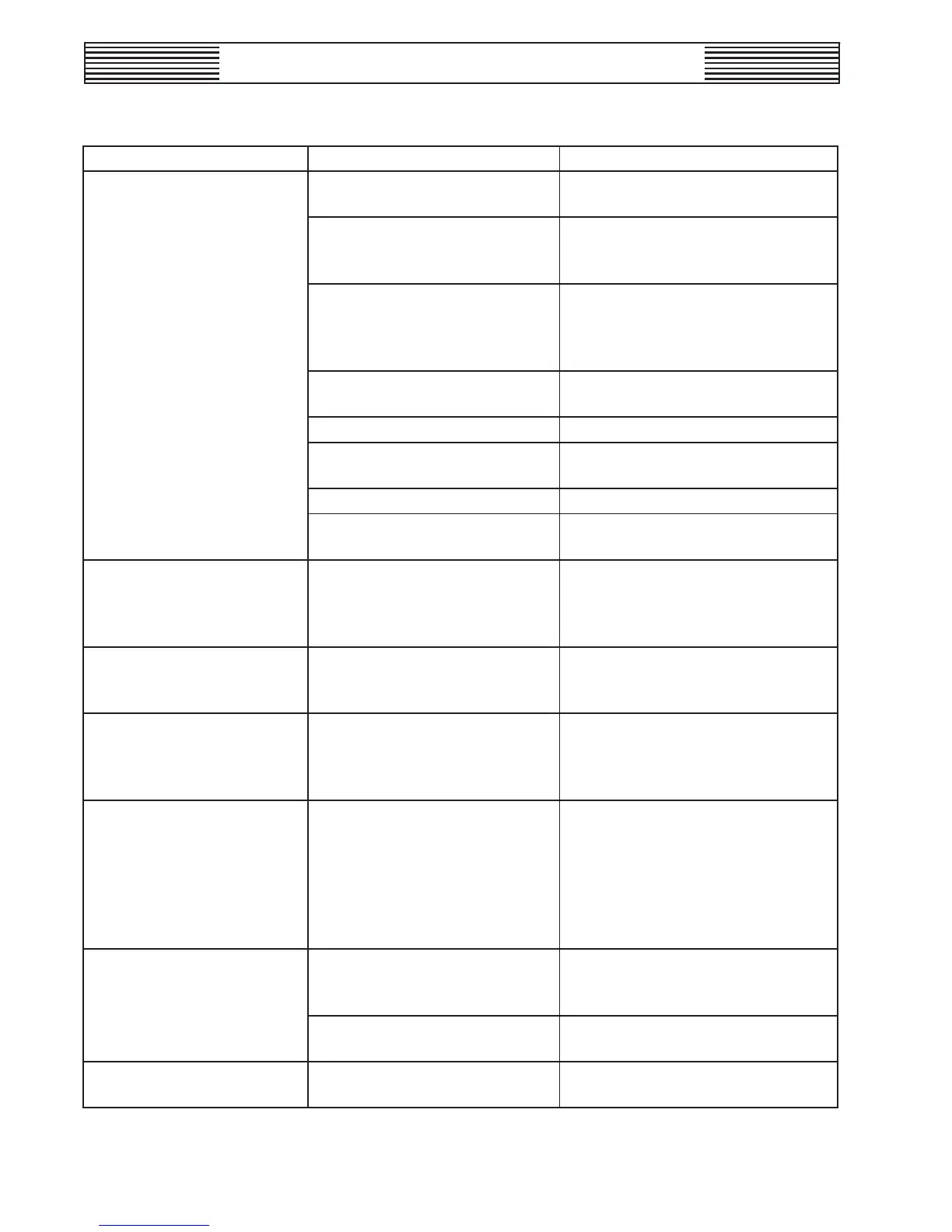

Table 4.3 - Troubleshooting

No Feed Rate or

Insufficient Feed Rate.

Zero or insufficient stroke

length.

Adjust to proper stroke length.

Ball valves on suction or

discharge side do not close

tightly.

Replace balls in valves. Remove

possible deposits in valves or pump

head. Replace pump head.

Gas in suction line or pump

head.

Check for cavitation and, if

necessary, use a suction line with

a larger inside diameter. Dilute the

liquid (sodium hypochlorite).

Air in suction line or pump

Bleed the suciton line and pump

Shut-off valves in suction or

discharge lines are closed.

Open valves.

Damaged drive mechanism.

Check mechanism and replace

No Feed Rate on Point of

Application, Though Pump

is Running.

Pressure relief valve is defective

or misadjusted, so that the

liquid flows back into the

Adjust pressure relief valve to

proper relief pressure.

Liquid is Emerging From

Pump Head Near the

Diaphragm.

Broken diaphragm or broken

crosshead oil seal.

Replace diaphragm, or replace oil

seal.

Pump is Pumping

Erratically or Feed Rate is

Inaccurate.

No back pressure.

Install back pressure valve into the

discharge line. Discharge pressure

must be at least 15 PSI more than

the suction pressure.

Erratic Diaphragm

Movement or No

Movement At All.

Diaphragm Movement

Does Not Correspond to

the Stroke Length Setting

Adjuster bearing (23) is loose

or completely unscrewed.

Remove the knob and tighten the

adjuster bearing. Clean the threads

of oil and apply "Locktite 242".

Extremely Noisy or Hot

Gear Box.

Insufficient lubrication or

defective bearing(s).

Check oil level through oil

check hole, if required, replace

bearing(s).

Incorrect worm shaft end play.

Add or remove shims to achieve

Motor Will Not Run.

Power off or fuse is blown.

Turn on the power. Replace the

fuse after correcting the cause.

WT.440.400.001.UA.IM.1012

51

Loading...

Loading...