Installation and operating instruction

Oil burner WL20/2-C Z

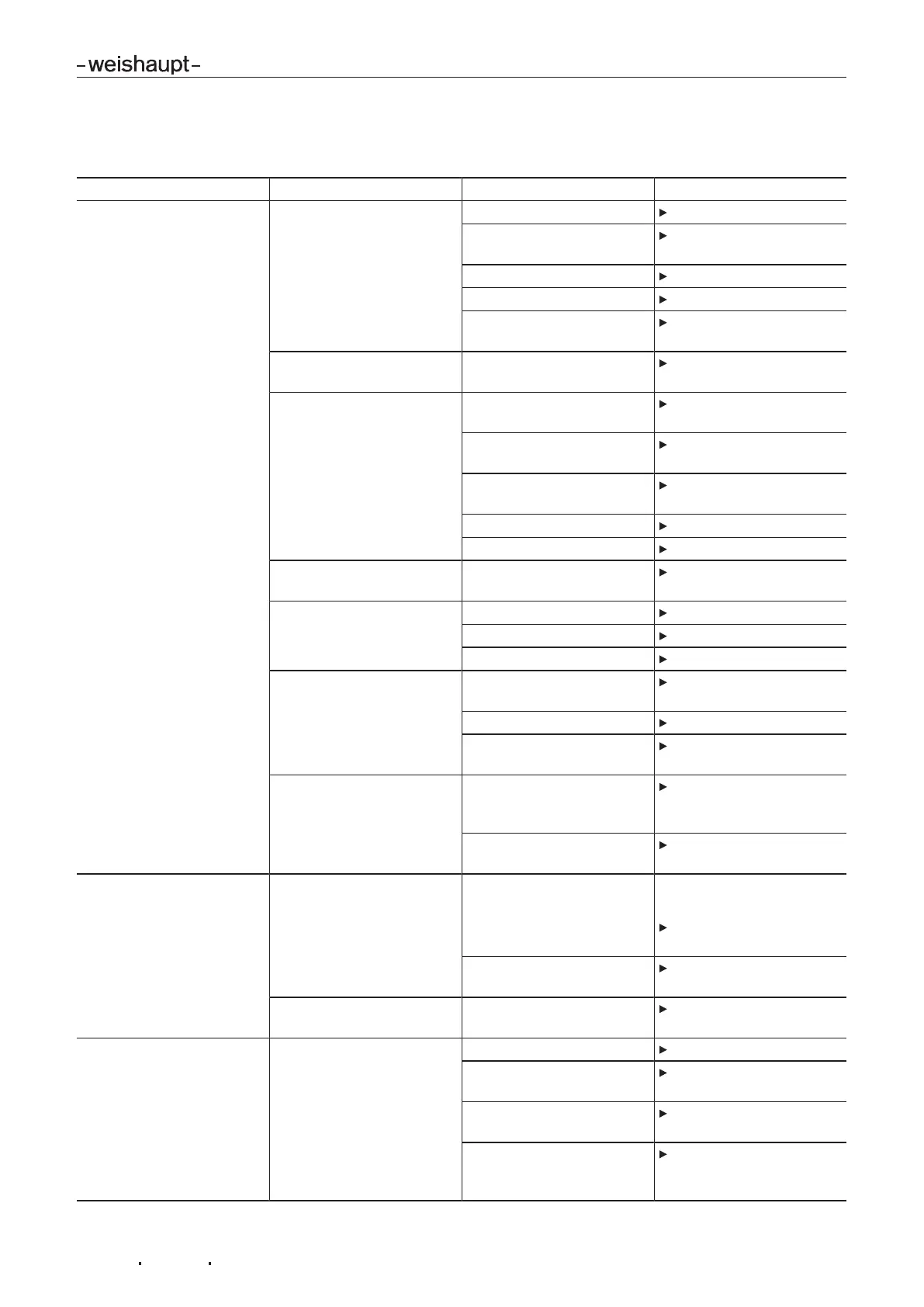

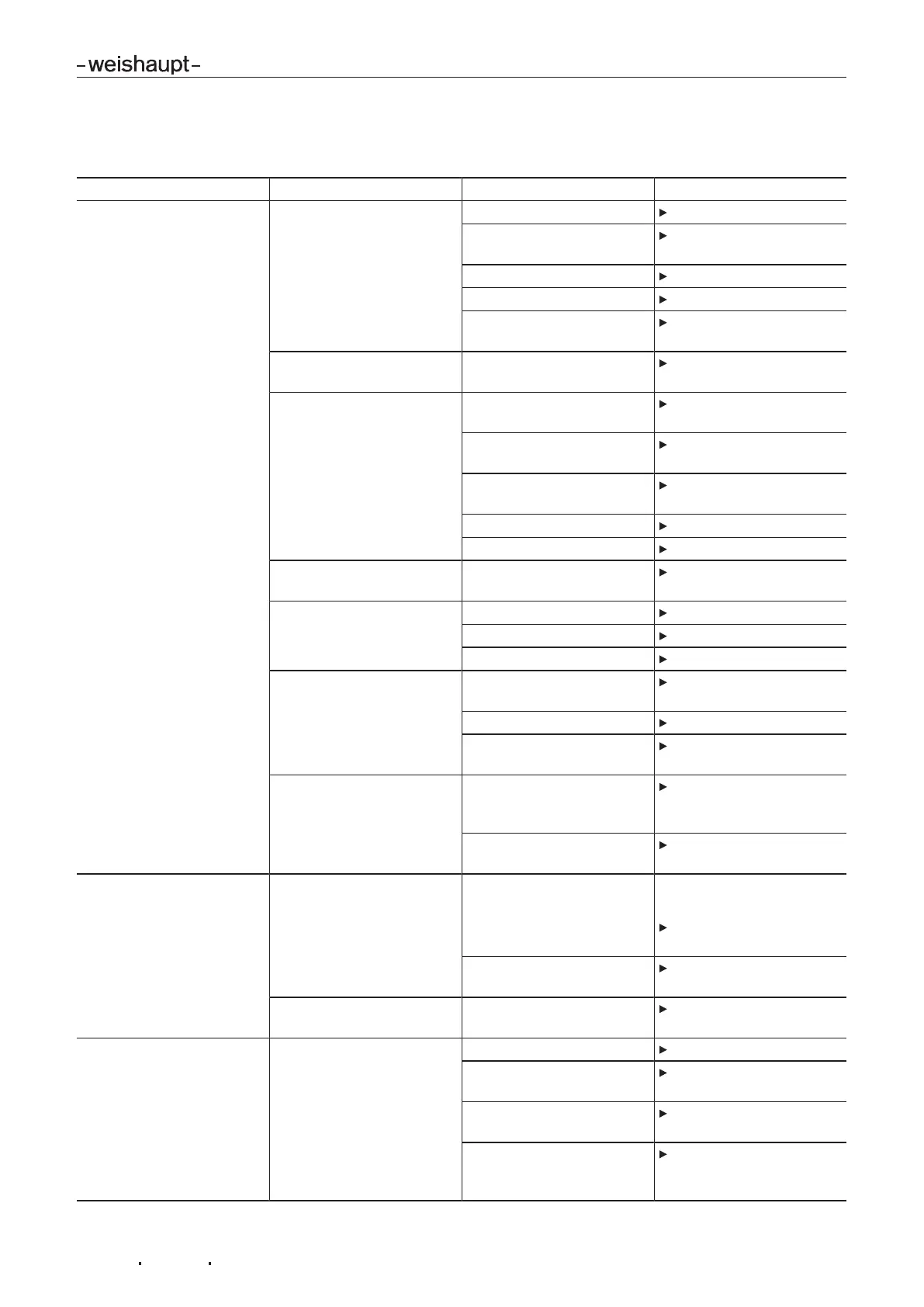

10 Troubleshooting

83307702 1/2019-04 La

55-80

Error codes with lockout

The following faults must only be rectified by qualified personnel:

Fault codes Fault Cause Rectification

2 x flashing

No flame,

end of safety time

Oil pump supplies no oil Oil supply leaking Check oil supply

Anti siphon valve does not

open

Check valve, if necessary

replace

Shut off device closed Open shut off device

Pre-filter strainer soiled Replace pre-filter strainer

Oil pump defective Replace oil pump

[ch.9.10]

No oil throughput at the

nozzle

Oil nozzle blocked Replace nozzle

No ignition Ignition electrode dirty or

wet

Clean ignition electrode

Ignition electrode spark gap

too big or short circuited

Set ignition electrode

[ch.9.5]

Ceramic insulator defective Replace ignition elec-

trode.

Ignition cable defective Replace ignition cable

Ignition unit defective Replace ignition unit

Solenoid valve does not

open

Coil defective Replace coil

Combustion manager does

not detect a flame signal

Flame sensor soiled Clean flame sensor

Flame sensor defective Replace flame sensor

Illumination insufficient Check burner setting

Burner motor does not run Oil pump seized Replace oil pump

[ch.9.10]

Capacitor defective Replace capacitor

Burner motor defective Replace burner motor

[ch.9.12]

No flame formation despite

ignition and oil supply

Nozzle distance incorrect Check nozzle distance,

adjust if necessary

[ch.9.7]

Mixing pressure too high Check mixing pressure

[ch.7.1.2]

Flashing 4 times

Flame simulation/

extraneous light

Flame signal prior to or after

operation

Extraneous light source

present

Extraneous light detection

from 13 μA

Find and eliminate ex-

traneous light source

Flame sensor defective Check flame sensor, if

necessary replace

Flame formation during pre-

purge

Solenoid valve leaking Replace oil pump

[ch.9.10]

Flashing 6 times

Actuator fault

Actuator does not reach tar-

get position within 10

seconds

Actuator plug unplugged Plug in actuator plug

Actuator defective Check actuator, replace if

necessary

Setting of limit switches in-

correct

Check position of limit

switches

Air damper/angle drive

blocked

Check freedom of move-

ment of air damper and /

or angle drive

Loading...

Loading...