10

MAINTENANCE

WARNING: Band saw blades are extremely sharp! Always wear gloves

when handling saw blades. Replace the band saw blade when it becomes

dull. A sharp blade gives the best cuts and helps extend the life of your

machine. Replacement blades (model no. 3975-056 and BB5650) can

be purchased from wenproducts.com.

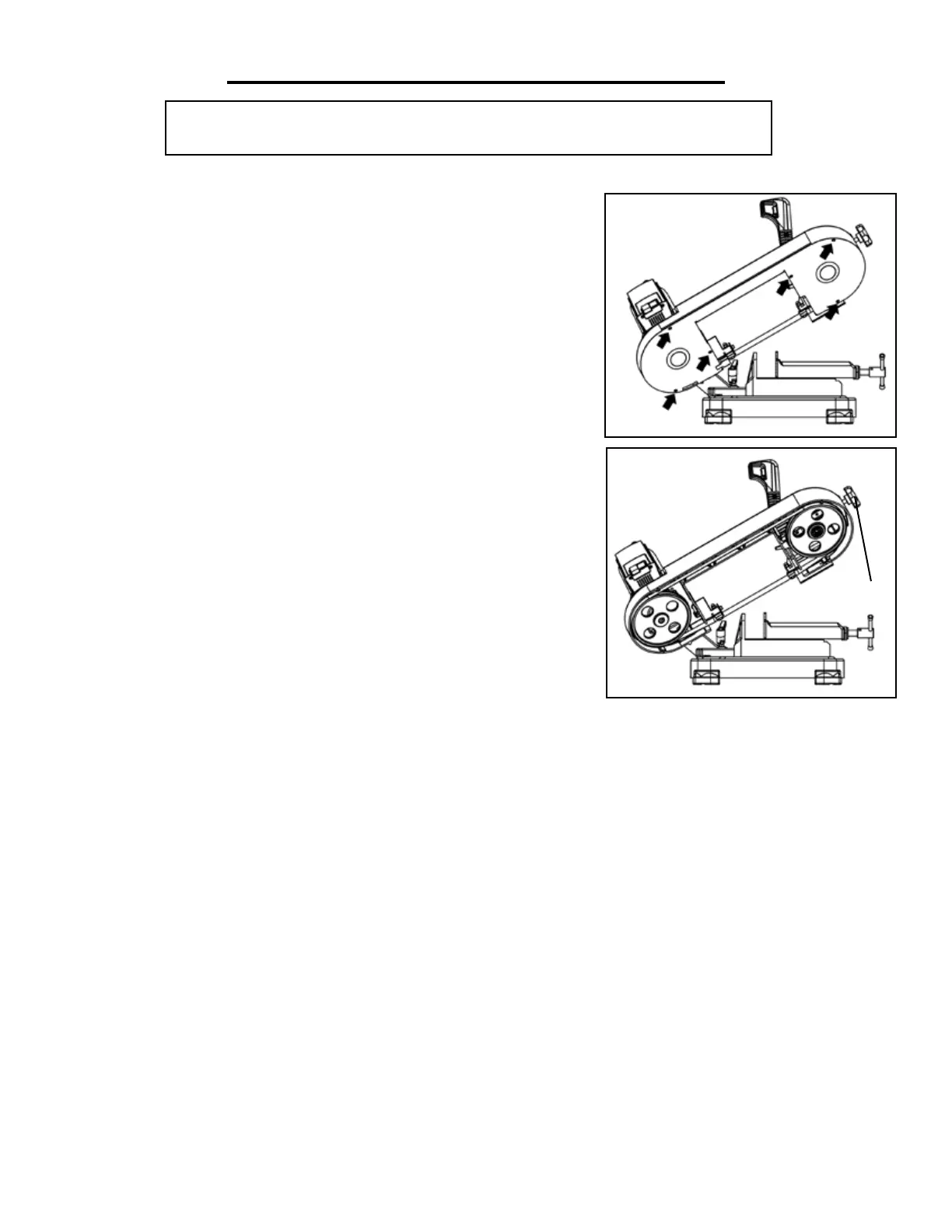

1. Remove the blade cover by unscrewing the six screws shown in Fig. K.

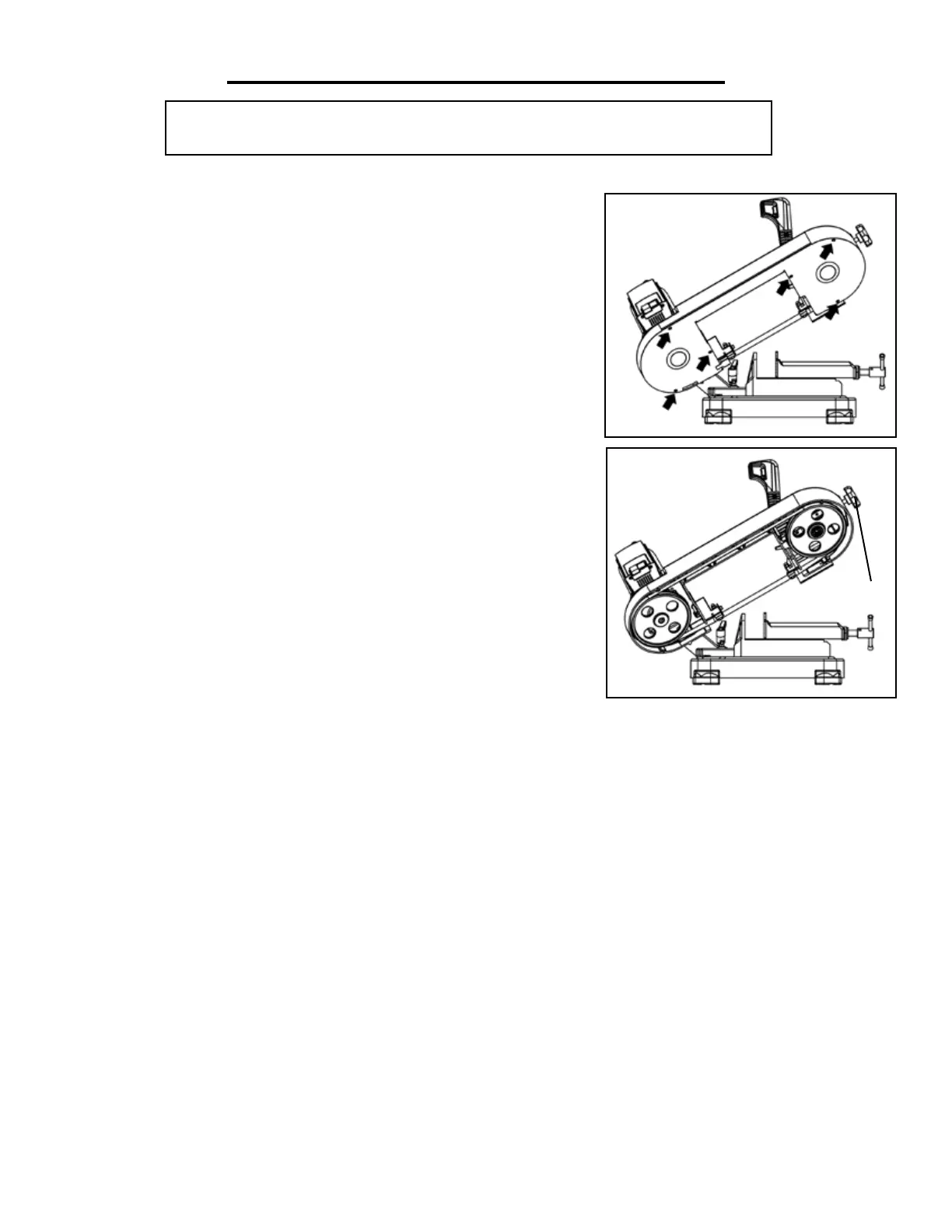

2. Relieve the blade tension by turning the blade tension adjustment

knob counterclockwise (Fig. L - 1).

3. Carefully remove the blade, first from between the guide bearings and

then from around the wheels.

4. Insert the new blade, first between the guide bearings and then around

the wheels.

NOTE: install the blade so that the teeth point in the direction of the

saw’s rotation.

5. Turn the blade tension adjustment knob until the blade is taut. The

blade is properly tensioned when pressing lightly on the side of the blade

moves the blade about 1/8 in. (Fig. L - 1).

6. Replace the blade cover and install the six screws (Fig. K).

7. Run the saw at no-load for 10 – 20 seconds to allow the blade to seat on the wheels.

8. Adjust the blade guide in preparation for the next cut.

Fig. K

Fig. L

1

Turn off the machine and disconnect the power supply

before conducting any maintenance work or adjusting any settings.

1. Routinely check the condition of the power supply cords and replace them if they are broken, worn or if inter-

nal wires are showing.

2. Use a brush to remove chips and other debris from the machine. Wipe off any cutting oil or other

processing residue from the blade, guide bearings, vise, and rest of the saw whenever necessary, and

especially before storing the saw.

TIP: apply a light coat of good-quality paste wax to the ways of the vise to protect it against damage and

rust, and to allow the movable jaw to slide more easily.

3. Keep the vise ways clean. Allowing chips to get under the movable vise jaw can cause damage to the

vise.

Loading...

Loading...