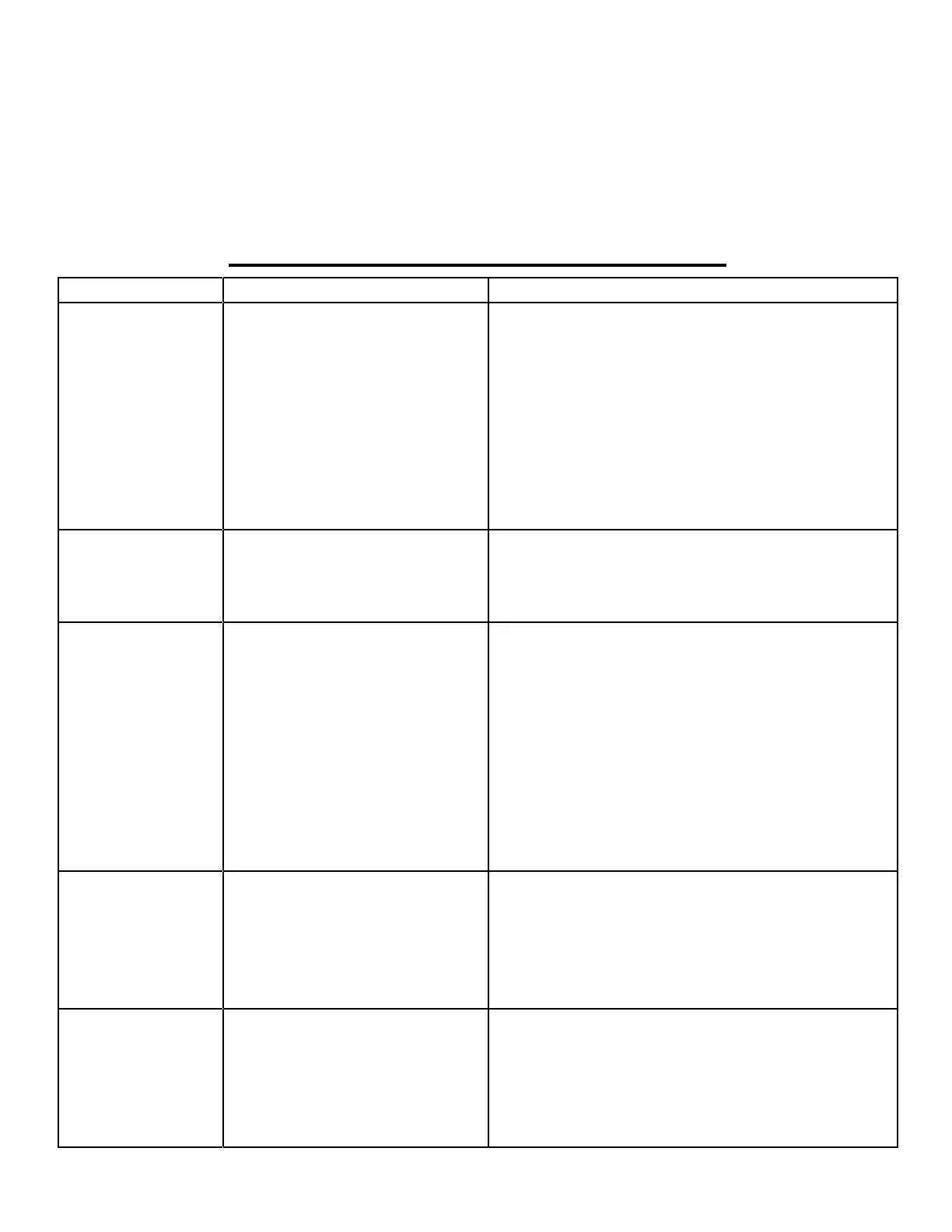

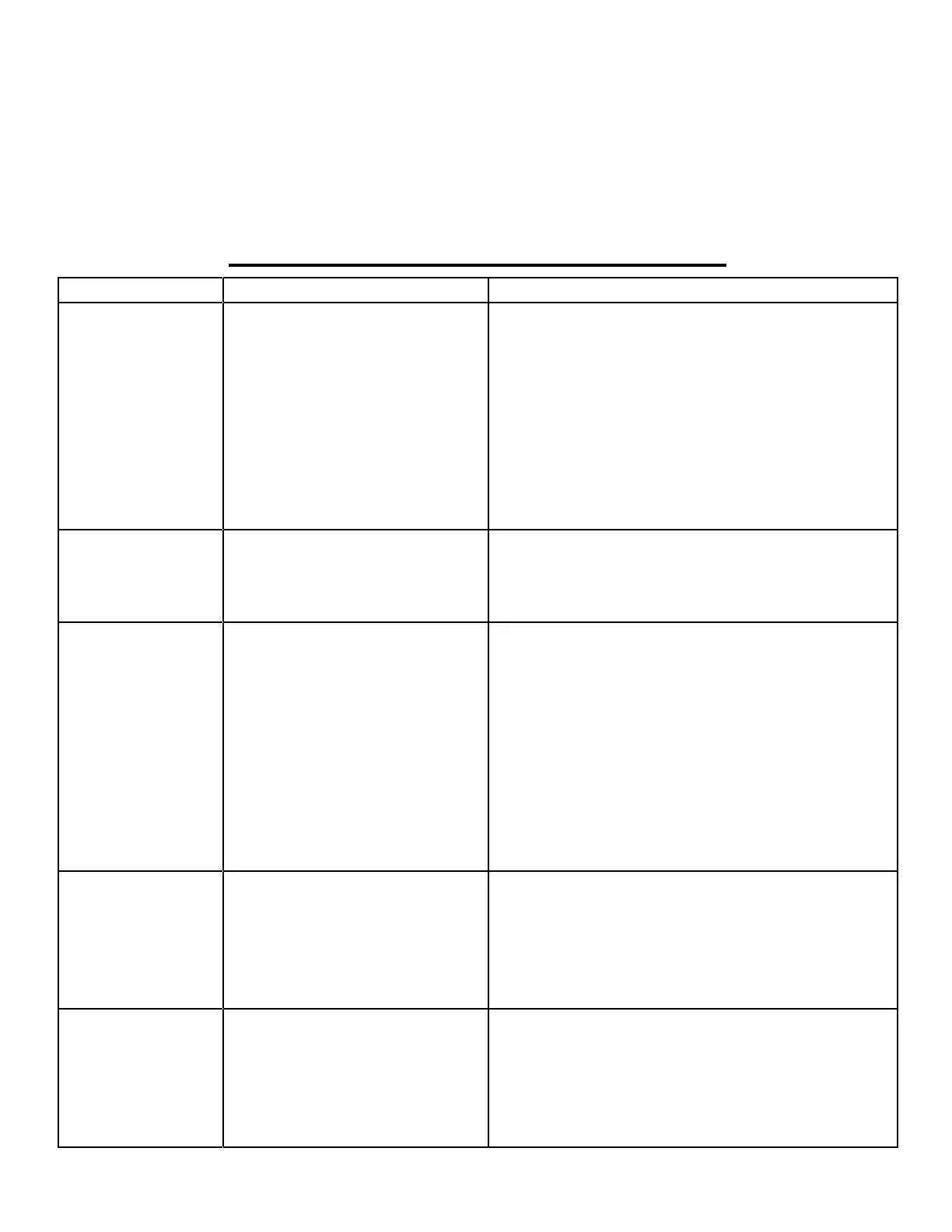

11

PROBLEM CAUSE SOLUTION

Saw does not turn

on.

1. Saw not plugged in.

2. Incorrect extension cord gauge.

3. Power button not pressed.

4. Circuit breaker tripped to pro-

tect machine.

5. Worn carbon brushes.

6. Defective switch, PCB, power

cord, or motor.

1. Plug saw in.

2. Use correct size and length on extension cord

(refer to p. 5).

3. Press green power button before pressing run but-

ton; ensure power indicator light is lit.

4. Wait a few minutes for the machine to cool. Press

the breaker to reset it. Reduce cutting speed and feed

rate.

5 & 6. Contact customer service at 1-800-232-1195

for assistance.

Power indicator light

does not turn on

after pressing green

power button.

1. Saw not plugged in.

2. Defective light, switch, power

cord, or PCB.

1. Plug saw in.

2. Contact customer service at 1-800-232-1195 for

assistance.

Inaccurate cut

1. Excessive cutting pressure.

2. Incorrect choice of blade teeth

profile or count relative to work-

piece.

3. Incorrect adjustment of the

sliding blade guide.

4. Incorrect choice of blade

speed.

5. Workpiece not tightly clamped

in vise.

6. Blade tension too low.

1. Reduce the cutting pressure. Let the machine do

the work.

2. Choose the proper blade for the given workpiece.

3. Check stationary blade guide alignment. Ensure

sliding blade guide is positioned as close to workpiece

as possible.

4. Adjust blade speed.

5. Clamp workpiece securely. Ensure vise jaws and

vise ways are clean. Use work stop to stabilize work-

piece.

6. Adjust blade tension (Fig. L - 1)

The blade tends to

protrude from the

guide.

1. Excessive blade tension.

2. Blade is slipping on wheels or

guide bearings due to presence

of cutting lubricant.

3. Blade is warped.

1. Adjust blade tension (Fig. L - 1)

2. Remove blade and clean wheels and guide bearings

to remove lubricant.

3. Remove blade and inspect it. Replace if neces-

sary. Blades can become warped through excess heat

buildup (overuse).

Noisy operation.

1. Blade is warped or improperly

seated on wheels or between

guide bearings.

2. Debris stuck in saw.

3. Loose fastener.

4. Worn bearing.

1. Remove blade and run saw to see

if noise persists. Inspect blade

for warpage.

2. Turn saw off and inspect for debris.

3. Inspect & tighten all fasteners.

4. Contact customer service.

TROUBLESHOOTING

4. Keep the machine’s hand grip clean in order to prevent accidental slippage during use.

5. If you do not intend to use the machine for longer than a week, clean it and store it in a cool, dry place

out of the reach of children. Relieve blade tension; this will prolong the life of the blade and prevent warpage.

6. Check the blade condition daily. Replace the blade if it is dull, warped, or shows other signs of damage.

Loading...

Loading...