ENGINE

ADJUSTMENTS

GLOW

PLUGS

The

glow

plugs are wired through the preheat

solenoid.

When

PREHEAT

is

pres~ed

at

the

control

panel

tlns

solenoid

should "click"

on

and the glow plug

ShOldd

begin

to

get

hot.

INSPECTION

To

inspect the plug, remove the electrical tenninal

connec-

.

tions,

then

unscrew or unclamp each

plug

from

the

cylinder

head. Thoroughly clean each plug's tip

and

threads

with

a'

soft brush

and

cleaning solution

to

remove

all

the carbon

and

oir"

deposits. While cleaning, examine the tip for wear

and

bum erosion;

if

it

has

eroded

too

much,

replace the

plug.

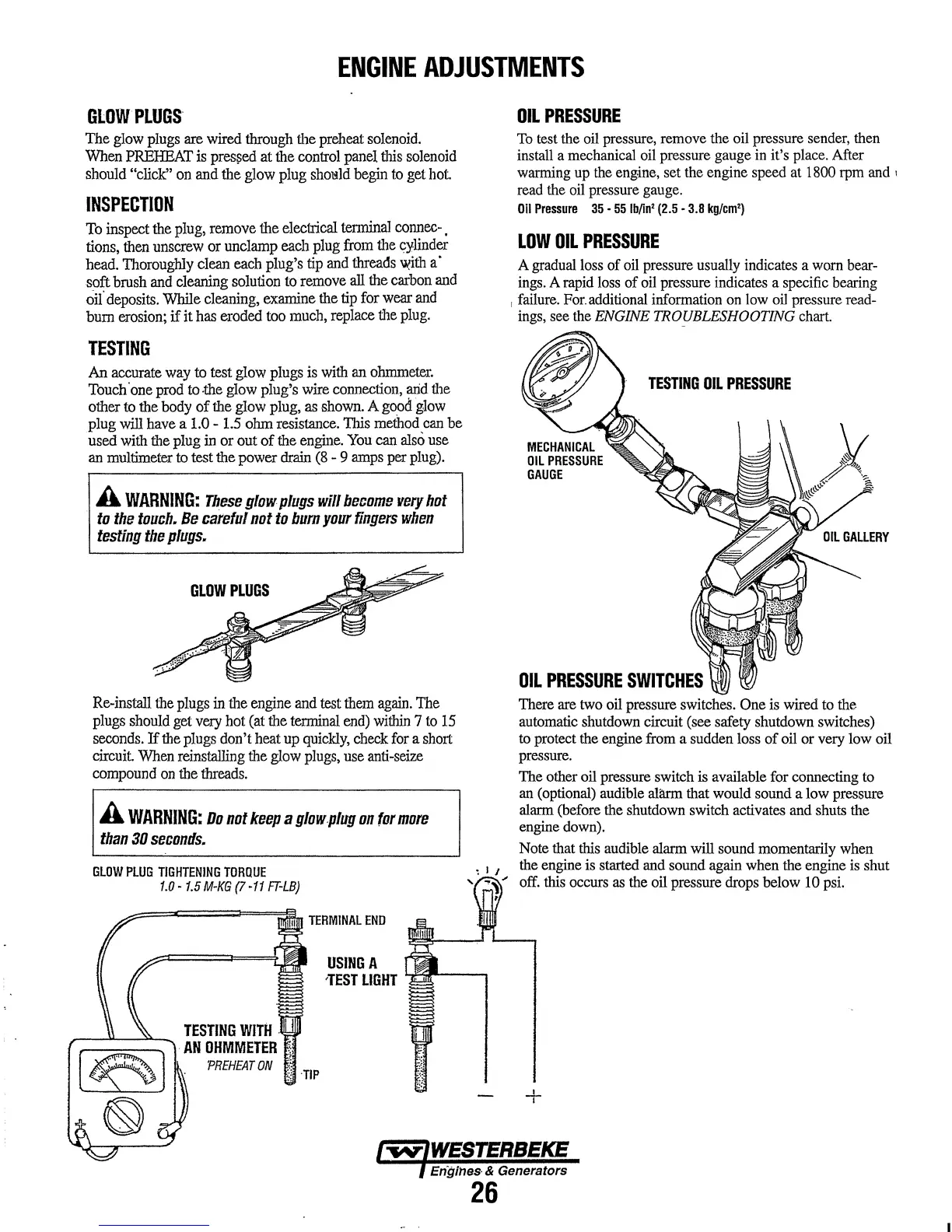

TESTING

An accurate

way

to

test glow plugs

is

with

an

ohmmeter.

Touch'one prod to·the glow plug's wire connection,

arid

the

other

to

the

body

of the glow plug,

as

shown.

A

good

glow

plug will have a 1.0 -

1.5

ohm resistance.

This

method

can

be

used

with

the plug

in

or out of the engine.

You

can

also

use

an

multimeter

to

test the power drain

(8

- 9

amps

per

plug).

A

WARNING:

These

glow

plugs

will

become

very

hot

to

the

touch.

Be

careful

not

to

burn

your

fingers

when

testing

the

plugs.

GLOW

PLUGS

Re-install

the

plugs

in

the engine

and

test

them

again.

The

plugs should get

very

hot (at

the

tenninal

end)

within

7

to

15

seconds.

If

the

plugs don't heat

up

quickly,

check

for

a short

circuit. When reinstallillg the

glow

plugs,

use

anti-seize

compound

on

the

threads.

A

WARNING:

00

not

keep

a

g/owp/ug

on

for

more

than

30

seconds.

GLOW

PLUG

TIGHTENING

TORQUE

1.0-1.5M-KG(7-11

FT-L8)

TESTING

WITH

.

.

AN

OHMMETER

PREHEAT

ON

TERMINAL

END

USING

A

'TEST

LIGHT

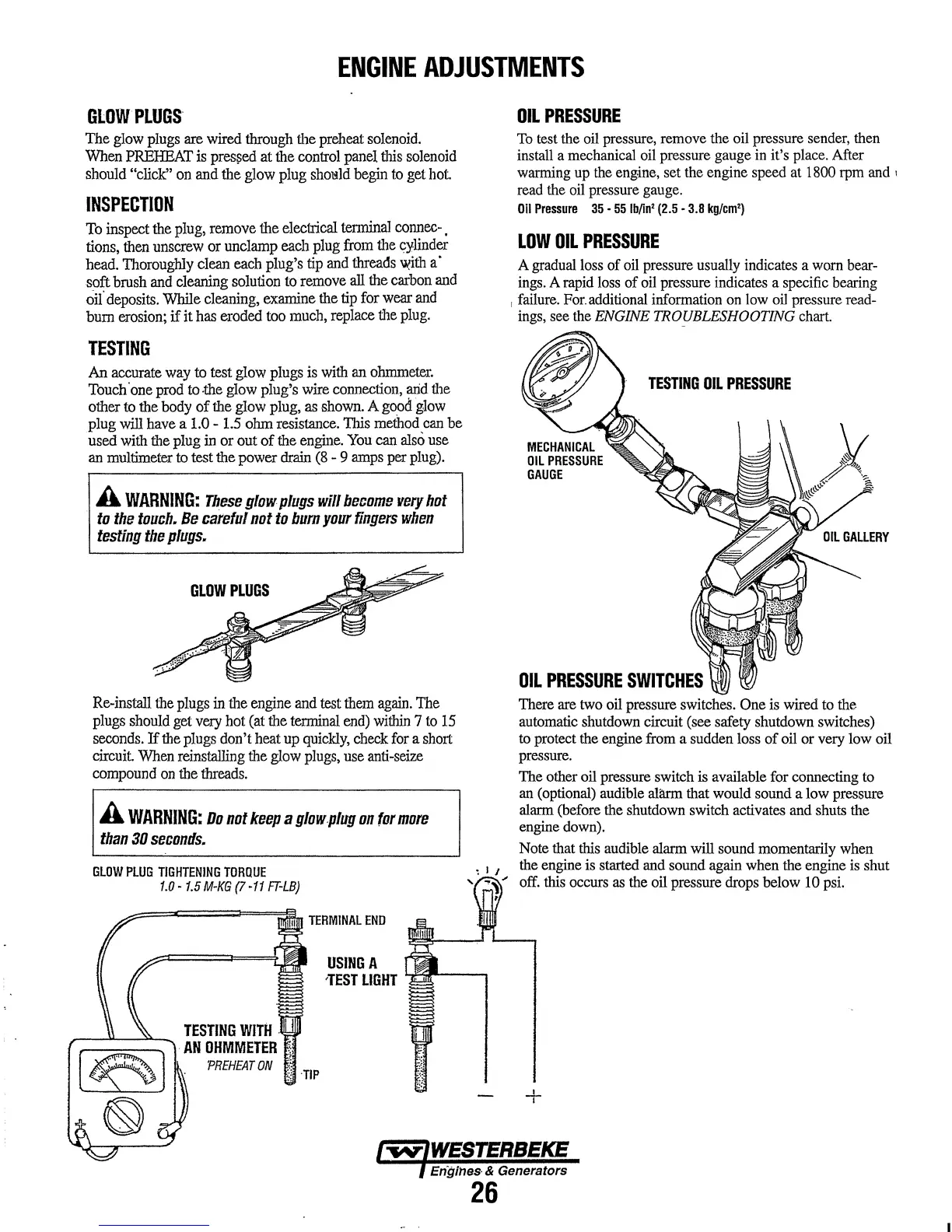

OIL

PRESSURE

To

test

the

oil

pressure, remove the

oil

pressure

sender,

then

install

a mechanical

oil

pressure gauge

in

it's

place.

After

warming

up

the

en~ine,

set the engine

speed

at

1800

rpm

and

,

read

the

oil

pressure

gauge.

Oil

Pressure

35

-

55

Ib/ln

2

(2.5

•

3.B

kg/cm

2

)

LOW

OIL

PRESSURE

A

gradual

loss

of

oil

pressure usually indicates a

worn

bear-

ings.

A rapid

loss

of

oil

pressure indicates a

specific

bearing

I

failure.

For.additional information

on

low

oil

pressure

read-

ings,

see

the

ENGINE TROUBLESHOOTING

chart.

TESTING

OIL

PRESSURE

OIL

PRESSURE

SWITCHES

There

are

two

oil

pressure switches. One

is

wired

to

the

automatic

shutdown

circuit

(see

safety shutdown switches)

to

protect the engine

from

a sudden loss of

oil

or

very

low oil

pressure.

The

other

oil

pressure switch

is

available

for

connecting

to

an

(optional)

audible alarm that

would

sound a

low

pressure

alarm

(before

the

shutdown switch activates and shuts

the

engine

down).

Note that

this

audible

alarm

will sound momentarily

when

the

engine

is

started

and

sound again when the engine

is

shut

off.

this

occurs

as

the

oil

pressure

drops

below

10

psi.

+

Engines· & Generators

26

Loading...

Loading...