ENGINE

COOLING

CIRCUIT

RAW

WATER

CODLING

CIRCUIT

The raw water flow is created by a positive displacement

impeller pump. This pump draws water directly from the

ocean, lake,

or

river from a through-hull opening through a

hose to the water strainer. The raw water passes from the

strainer through the pump

to

a heat exchanger (through the

heat exchanger tubes) where it cools the engine's circulating

fresh water coolant. The raw water is then discharged into the

water injected exhaust elbow, mixing with, and cooling the

exhaust gasses. This mixture

of

exhaust gas and raw water is

driven through the stem tube and overboard.

Raw

Water

Pump

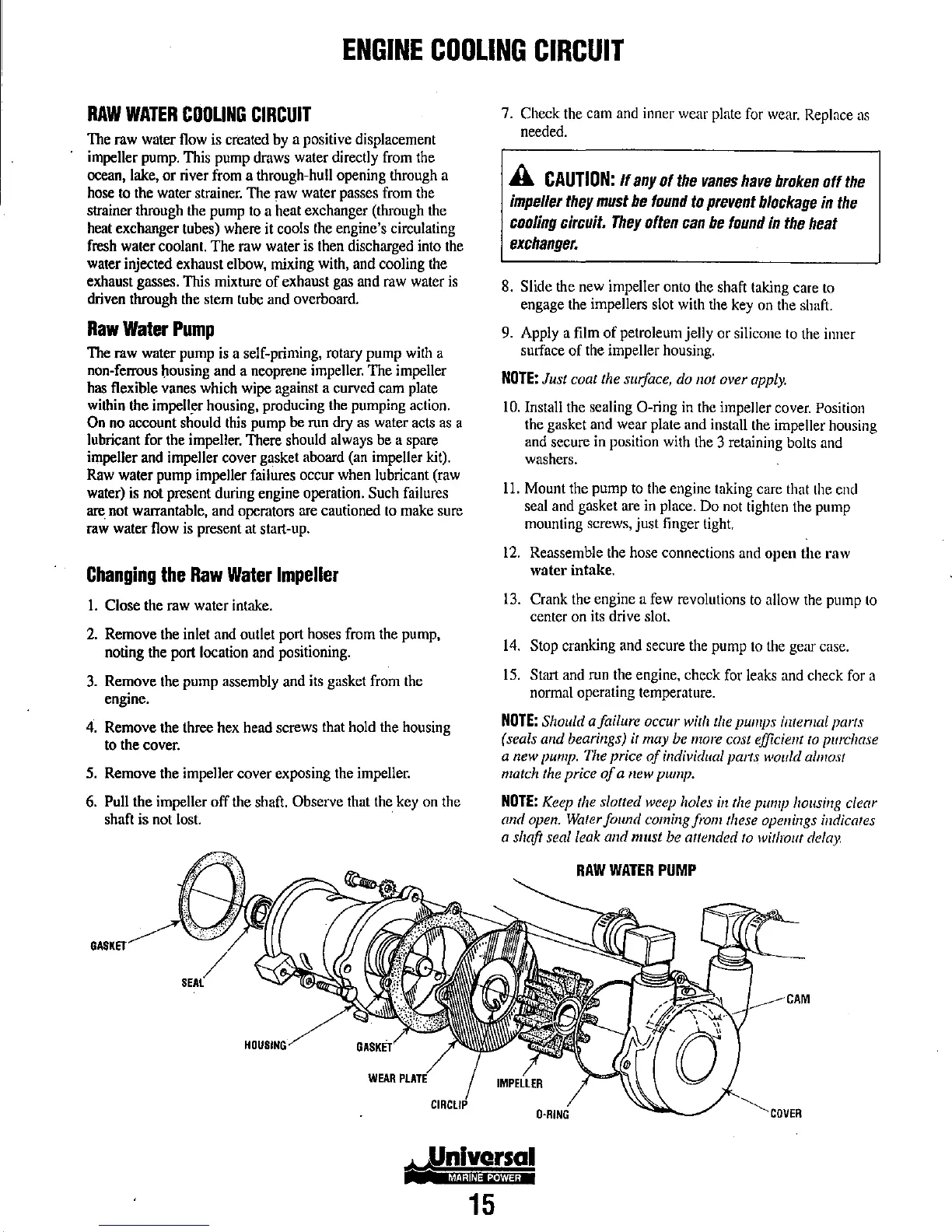

The raw water pump is a self-priming, rotary pump with a

non-ferrous housing and a neoprene impeller. The impeller

has flexible vanes which wipe against a curved cam plate

within the

impell~r

housing, producing the pumping action.

On no account should this pump be run dry as water acts

as

a

lubricant for the impeller. There should always be a spare

impeller and impeller cover gasket aboard (an impeller kit).

Raw water pump impeller failures occur when lubricant (raw

water) is not present during engine operation. Such failures

are.

not warrantable, and operators are cautioned

to

make sure

raw water flow is present at start-up.

Changing

the

Raw

Water

Impeller

I.

Close the raw water intake.

2. Remove the inlet and outlet port hoses from the pump,

noting the port location and positioning.

3.

Remove the pump assembly and its gasket from the

engine.

4.

Remove the three hex head screws that hold the housing

to the cover.

5.

Remove the impeller cover exposing the impeller.

6.

Pull the impeller off the shaft. Observe that the key on the

shaft is not lost.

.

HOUSING

15

7. Check the cam and inner wear plate for wear. Replace as

needed.

A

CAUTION:

If

any

of

the

vanes

have

broken

off

the

impeller

they

must

be

found

to

prevent

blockage

in

the

cooling

circuit.

They

often

can

be

found

in

the

heat

exchanger.

8. Slide the new impeller onto the shaft taking care

to

engage the impellers slot with the key on the shaft.

9. Apply a film

of

petroleum jelly or silicone to the inner

surface

of

the impeller housing.

NOTE:

Just coat the swiaee, do Ilot over apply.

10.

Install the sealing O-ring in the impeller cover. Position

the gasket and wear plate and install the impeller housing

and secure in position with the 3 retaining bolts and

washers.

II.

Mount the pump to the engine taking care that the end

seal and gasket are in place. Do not tighten the pump

mounting screws, just finger tight.

12.

Reassemble the hose connections and

open

the

raw

water intake,

13. Crank the engine a few revolutions

to

allow the pump

to

center

on

its

drive

slot.

14.

Stop cranking and secure the pump

to

the gear case.

15.

Start and run the engine, check for leaks and check for a

normal

operating

temperature.

NOTE:

Should afai/ure occur with the pumps illtemal parts

(seals and bearings)

if

may

be more cost efficient to purchase

a new pump. The price

of

individual pans would almost

match the price

of

a new pump.

NOTE:

Keep the slotted weep holes

ill

the pump

hOllSillg

clear

and open. Water found coming from these openings indicates

a shaft seal leak alld

IIlllst

be aI/ended

to

withow delay.

RAW

WATER

PUMP

O-RING

COVER

Loading...

Loading...