ENGINE

ADJUSTMENTS

NOTE:

UNIVERSAL recommends that the following engine

adjustments be performed

by

a competent engine mechanic.

The infonnation below is provided

to

assist the mechanic.

NO!IMAI,LYI?PEIV

5

PSI

RAfEO

TESTING

ENGINE

COMPRESSION

Make certain the oil level (dipstick) is

at

the correct level and

the

air

intake filter is clean.

The

battery

and

starter

motor

must

also

he

in good condition.

1. Warm the engine to normal operating temperature.

2.

Move

the control lever to a position for shutting

off

the fuel.

(Disconnect

the

wires

if

a fuel

shutdown

solenoid is used).

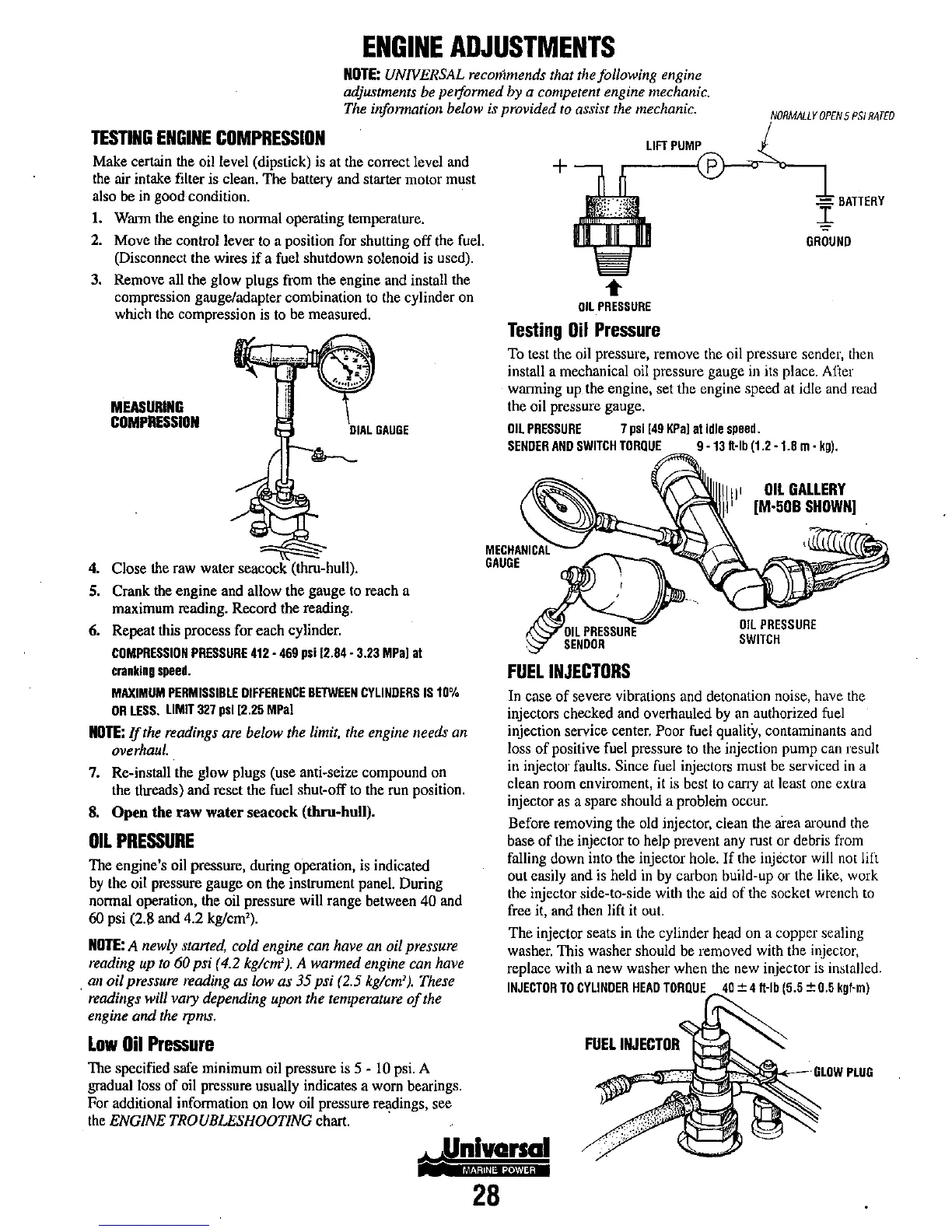

3. Remove all the

glow

plugs from the engine and install the

compression gauge/adapter combination to the cylinder on

which the compression

is

to be measured.

MEASURING

COMPRESSION

~

DIAL

GAUGE

4.

Close

the raw

water

seacock

(thru-hull).

5.

Crank

the

engine

and

allow

the

gauge

to reach a

maximum

reading. Record the reading.

6.

Repeat

this process

for

each

cylinder.

COMPRESSION

PRESSURE

412

•

469

psi

12.84·3.23

MPal

at

cranking

speed.

MAXIMUM

PERMISSIBLE

DIFFERENCE

BElWEEN

CYLINDERS

IS

10%

OR

LESS.

LIMIT

327

psi

12.25

MPal

NOTE:

If

the readings are below the limit, the engine needs an

overhaul.

7.

Re-installthe

glow

plugs

(use

anti-seize

compound

on

the threads)

and

reset the fuel shut-off to the run position.

S.

Open

Ibe

raw

water soacock

(lbru-hull).

OIL

PRESSURE

The

engine's

oil pressure, during operation, is indicated

by the

oil

pressure

gauge

on

the instrument panel.

During

normal operation, the oil pressure will range between

40

and

60 psi (2.8

and

4.2

kg/cm').

NOTE:

A newly staned, cold engine can have

an

oil pressure

reading up to

60

psi (4.2 kg/ctri'J. A warmed engine can have

. an oil pressure

I~ading

as low

as

35 psi (2.5 kg/cm'

J.

These

readings will vary depending upon the temperature

of

the

engine

and

the rpms.

Low

Oil

Pressure

The specified safe

minimum

oil pressure is 5 - 10 psi. A

gradual loss

of

oil pressure usually indicates a worn bearings.

For

additional infonnation on low oil pressure

re~dings,

see

the ENGINE TROUBLESHOOTING chart.

LIFT

PUMP

+

BATTERY

GROUND

...

OIL

PRESSURE

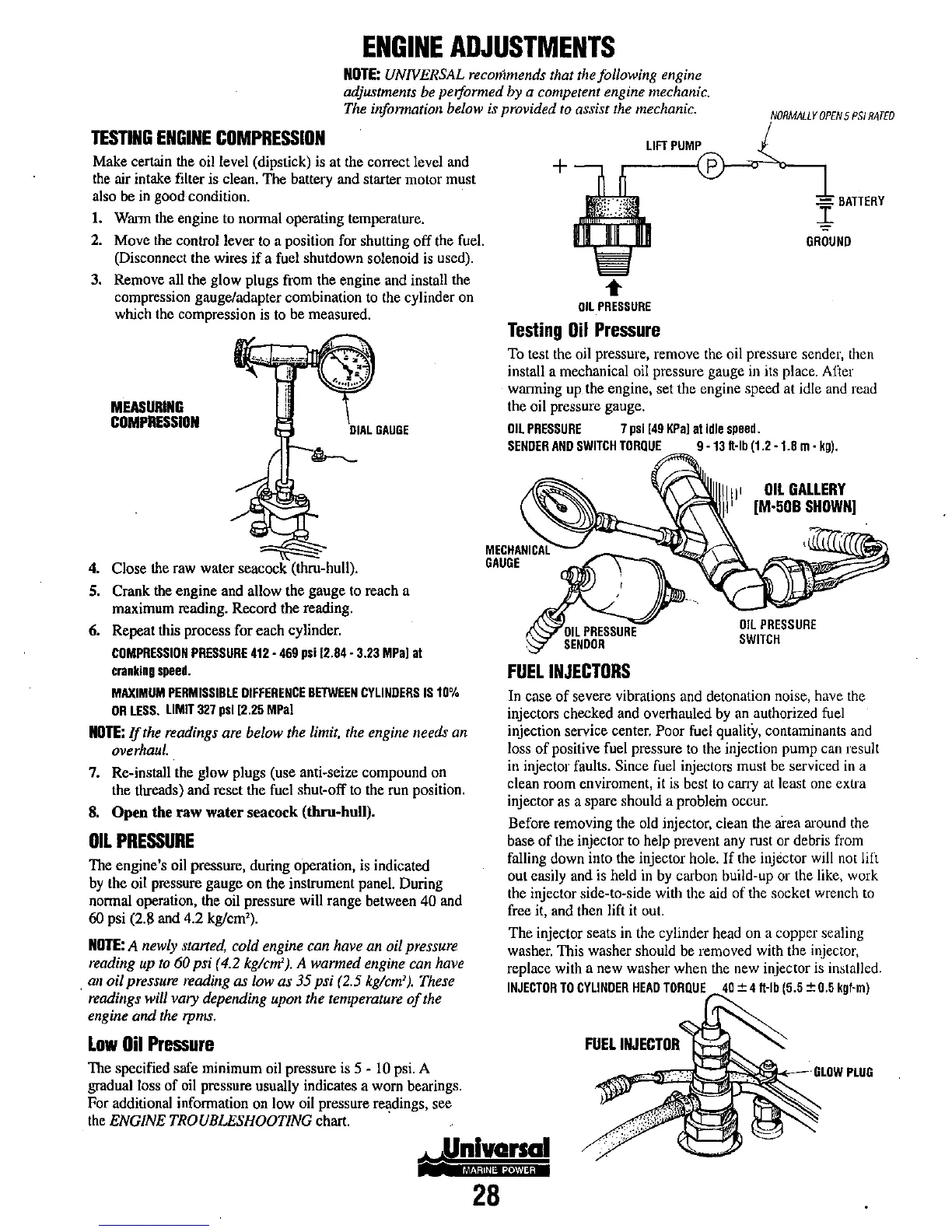

Testing

Oil

Pressure

To

test the oil pressure, remove the oil pressure sender, then

install a mechanical oil pressure gauge in its place. After

warming

up the engine,

set

the engine

speed

at

idle and read

the oil pressure gauge.

OIL

PRESSURE

7

psi

(49

KPal

alldle

speed.

SENDER

AND

SWITCH

TORQUE

9 ·13

R·lh

(1.2

·1.8 m •

kg).

FUEL

INJECTORS

OIL

GALLERY

IM-50B

SHOWN]

In case

of

severe vibrations and detonation noise, have the

injectors checked

and

overhauled by an authorized fuel

injection service center.

Poor

fuel quality, contaminants and

loss

of

positive fuel pressure to the injection

pump

can

result

in

injector faults. Since fuel injectors must be serviced in a

clean room enviroment,

it is best to carry at least one extra

injector as a

spare

should a problem occur.

Before removing the old injector, clean the

area around the

base

of

the injector to help prevent any rust or debris from

falling

down

into the injector hole.

If

the injector will not lift

out easily and is held in by carbon build-up

or

the like, work

the injector side-to-side with the aid

of

the socket wrench to

free it, and then lift it out.

The

injector seats in the cylinder head

on

a copper sealing

washer. This washer should be removed with the injector,

replace with a new washer

when

the new injector is installed .

INJECTOR

TO

CYLINDER

HEAD

TORQUE

±4

R·lh

(5.5

±0.5

kgl·m)

FUEL

INJECTOR

•

.Unlvarsal

28

Loading...

Loading...