ENGINE

ADJUSTMENTS

. -

..

~

.

NOTE:

UNIVERSAL recommends

thanhe

following engine

~adjustments

be peiformed by a competent engine mechanic.

The information below is provided to assist the mechanic.

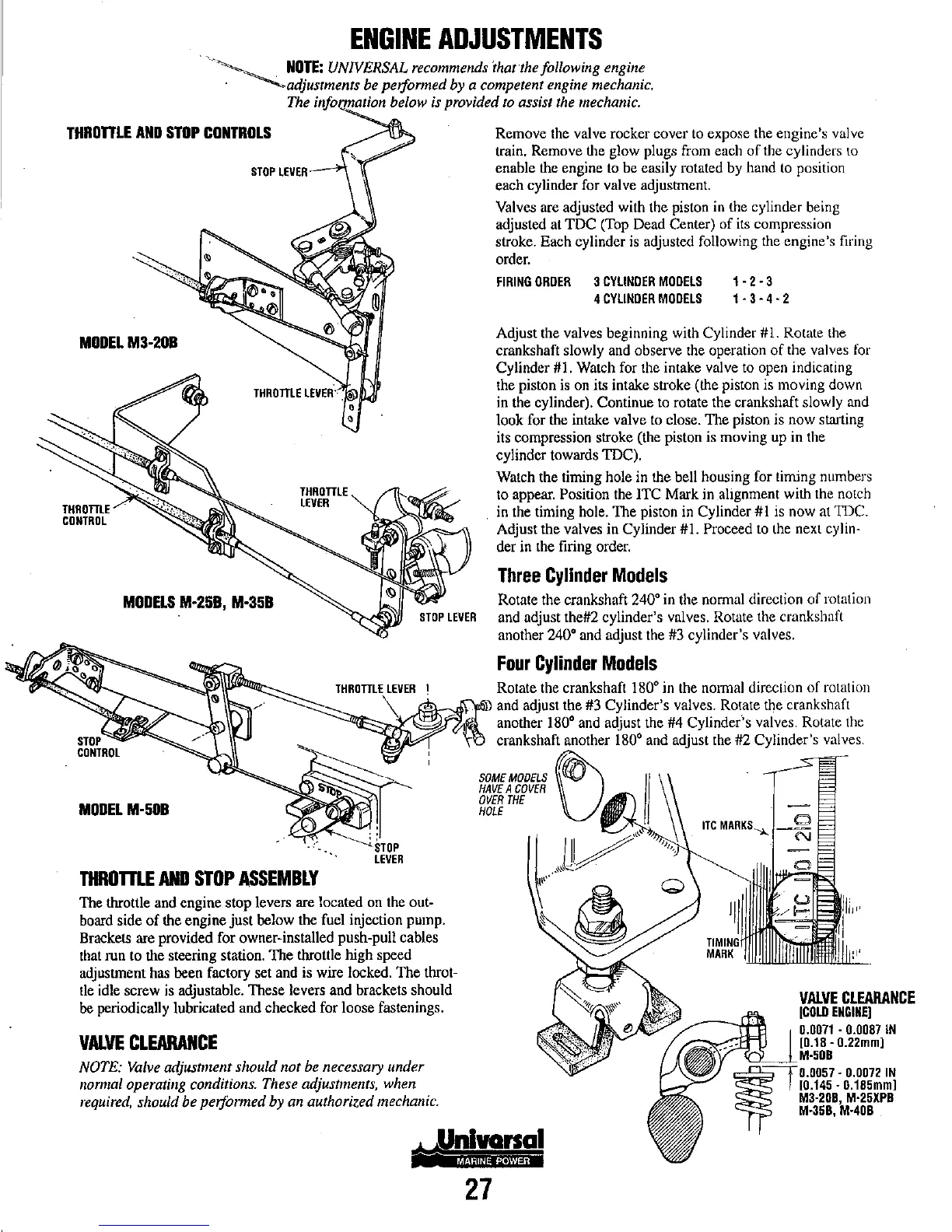

THROnLE

ANO

STOP

CONTROLS

MOOEL

M3-20B

THROTTLE

LEVER'

.

,

•

THROTTLE

CONTROL

MODELS

M-2SB,

M-3SB

MODEL

M-SOB

THROTTLE

LEVER

THROrnE

AND

STOP

ASSEMBLY

The throttle and engine stop levers are located on the out-

board side

of

the engine

just

below the fuel injection pump.

Brackets are provided for owner-installed push-pull cables

that run to the steering station.

The

throttle high speed

adjustment has been factory set and is wire locked.

The

throt-

tle idle screw is adjustable. These levers and brackets should

be periodically lubricated and checked for loose fastenings.

VALVE

CLEARANCE

NOTE:

Valve

adjustment should not be necessary under

normal operating conditions. These adjustments, when

required,

should be peiformed by an authorized mechanic.

Remove the valve rocker cover to expose the engine's valve

train. Remove the glow plugs from each

of

the cylinders

to

enable the engine to be easily rotated by hand

to

position

each cylinder for valve adjustment.

Valves are adjusted with the piston in the cylinder being

adjusted at

TOC

(Top Dead Center)

of

its compression

stroke. Each cylinder is adjusted following the engine's firing

order.

FIRING

OROER

3

CYLINOER

MODELS

4

CYLINDER

MODELS

1-2-3

1·3-4-2

Adjust the valves beginning with Cylinder #1. Rotate the

crankshaft slowly and observe the operation

of

the valves for

Cylinder #1. Watch for the intake valve to open indicating

the piston is on its intake stroke (the piston is moving down

in the cylinder). Continue to rotate the crankshaft slowly and

look for the intake valve to close. The piston is

now

starting

its compression stroke (the piston is moving up in the

cylinder towards TDC).

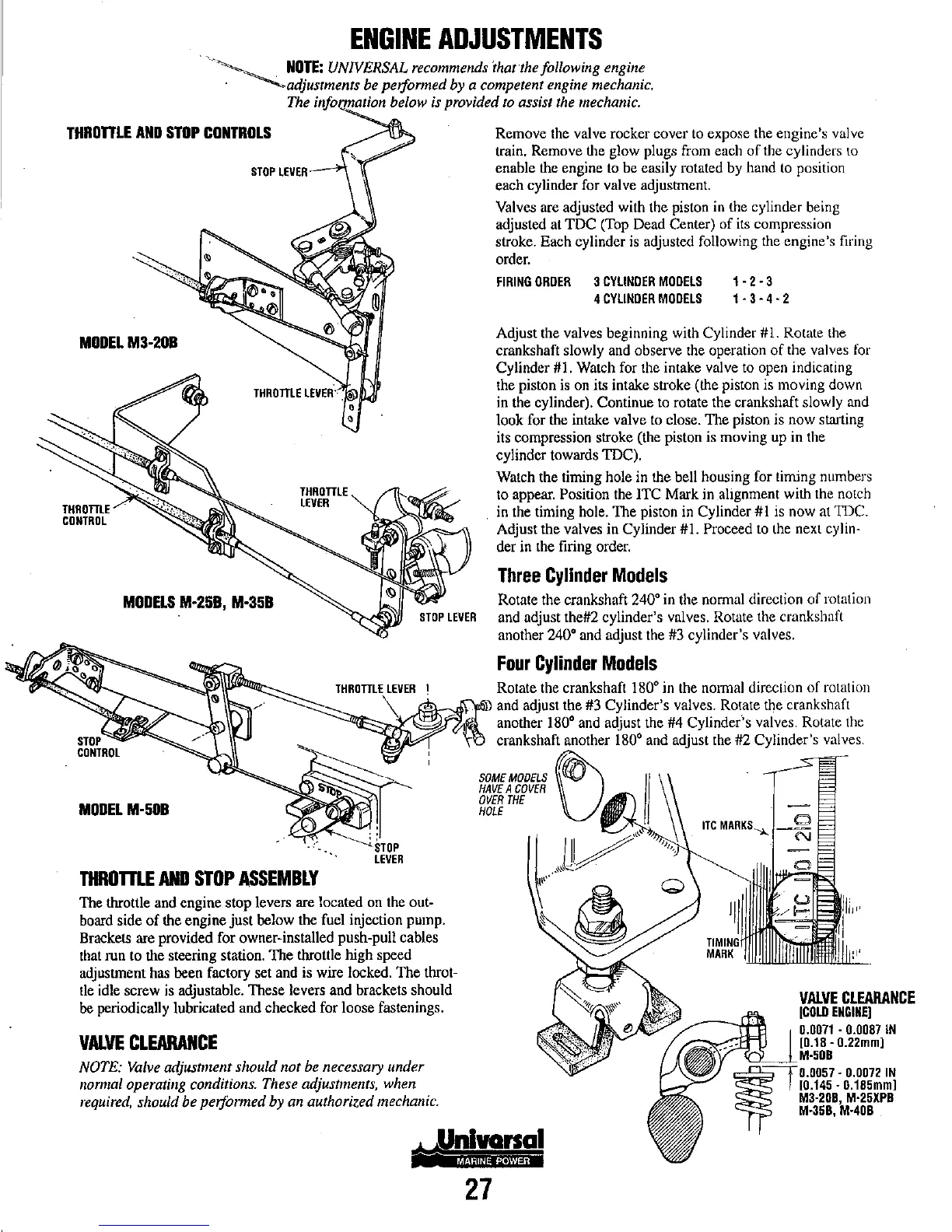

Watch the timing hole in the bell housing for timing numbers

to appear.

Position the ITC Mark in alignment with the notch

in the timing hole.

The

piston in Cylinder

#1

is now at TOC.

Adjust the valves in Cylinder #1.

Proceed to the next cylin-

der in the firing order.

Three

Cylinder

Models

Rotate the crankshaft

240'

in the normal direction

of

rotation

and adjust the#2 cylinder's valves. Rotate the crankshaft

another

240'

and adjust the #3 cylinder's valves.

Four

Cylinder

ModelS

Rotate the crankshaft

180'

in the nmmal direction

of

rotation

and adjust the #3 Cylinder's valves. Rotate the crankshaft

another

180'

and adjust the #4 Cylinder"s valves. Rotate the

crankshaft another

180'

and adjust the #2 Cylinder'S valves.

SOME

MOOELS

~0

HAVE

A

COVER

OVER

THE

HOLE

27

VALVE

CLEARANCE

(COLO

ENGINE(

0.0071

·0.0087

tN

[0.18

-

0.22mml

M·5DB

,,=,,=.=!=t

0.0057

-

0.0072

IN

10.145

-

0.185mml

M3·20B,

M·25XP8

M-358,

M·40B

Loading...

Loading...