ENGINE

COOLING

CIRCUIT

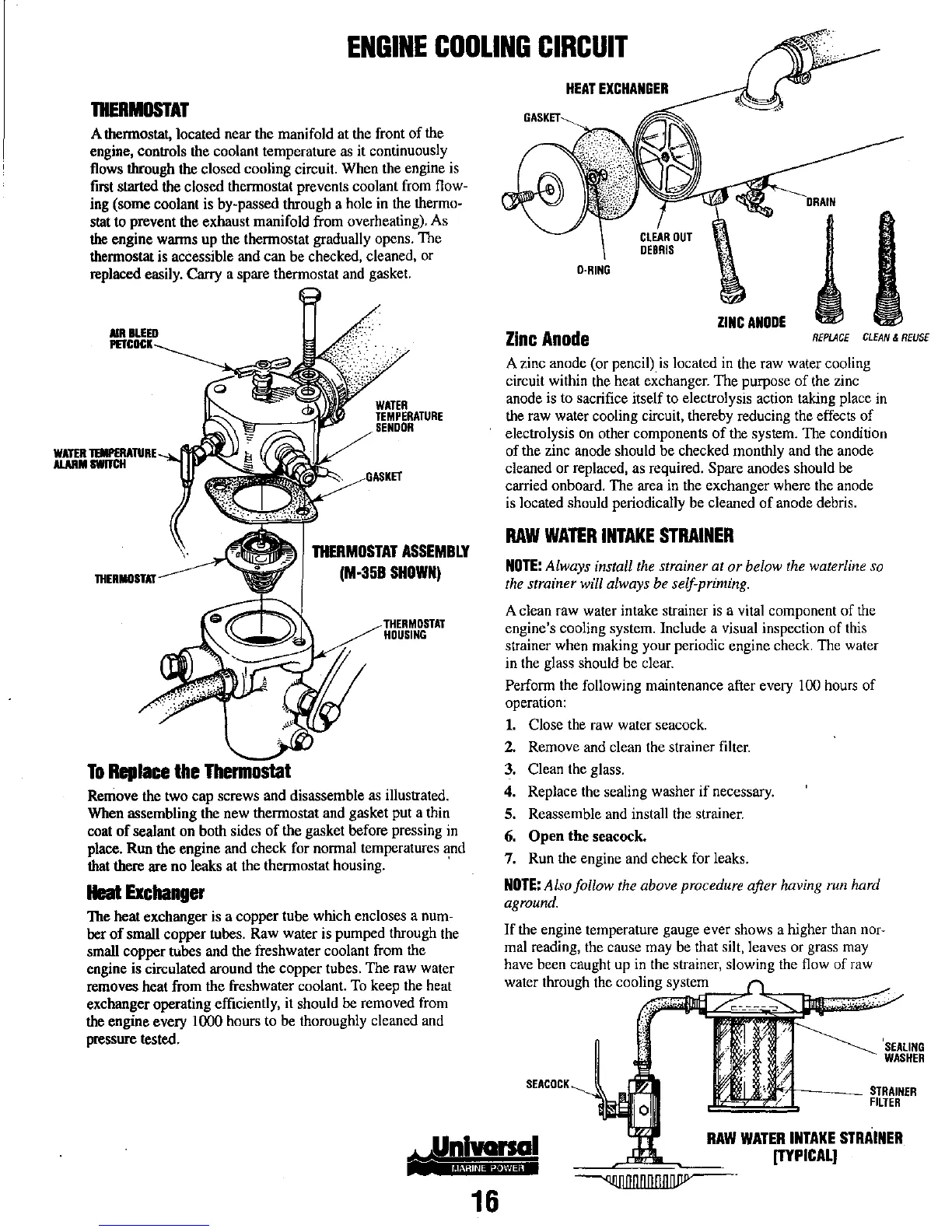

THERMOSTAT

A \hennostat, located near the manifold at the front

of

the

engine, controls the coolant temperature

as

it continuously

flows through the closed cooling circuit. When the engine is

flTSt

started the closed thennostat prevents coolant from flow-

ing (some coolant is by-passed through a hole in the thenno-

stat to prevent the exhaust manifold from overheating). As

\he engine warms

up

the thennostat gradually opens. The

thennostat is accessible and can

be

checked. cleaned. or

replaced easily. Carry a spare thennostat and gasket.

To

Replace

the

Thermostat

WATER

TEMPERATURE

SENDDR

THERMOSTAT

ASSEMBLY

(M-35B

SHOWN)

THERMOSTAT

HOUSING

Remove the two cap screws and disassemble as illustrated.

When assembling the new thennostat and gasket put a thin

coat

of

sealant on both sides

of

the gasket before pressing in

place. Run the engine and check for

nonnal

temperatures and

that there are

no

leaks at the thennostat housing. .

Heat

Exchanger

The beat exchanger is a copper tube which encloses a num-

ber

of

small copper tubes. Raw water is pumped through the

small copper tubes and the freshwater coolant from the

engine is circulated around the copper tubes.

The

raw water

removes heat from the freshwater coolant. To keep the heat

exchanger operating efficiently. it should be removed from

the engine every

1000 hours to be thoroughly cleaned and

pressure tested.

16

HEAT

EXCHANGER

ZINC

ANODE

Zinc

Anode

REPLACE

CLEAN

&

REUSE

A zinc anode (or pencil)

is

located in the raw water cooling

circuit within the heat exchanger.

The

purpose

of

the zinc

anode is to sacrifice itself to electrolysis action taking place

in

the raw water cooling circuit, thereby reducing the effects

of

electrolysis on other components

of

the syslem. The condition

of

the zinc anode should

be

checked monthly and the anode

cleaned

or

replaced. as required. Spare anodes should be

carried onboard. The area in the exchanger where the anode

is located should periodically be cleaned

of

anode debris.

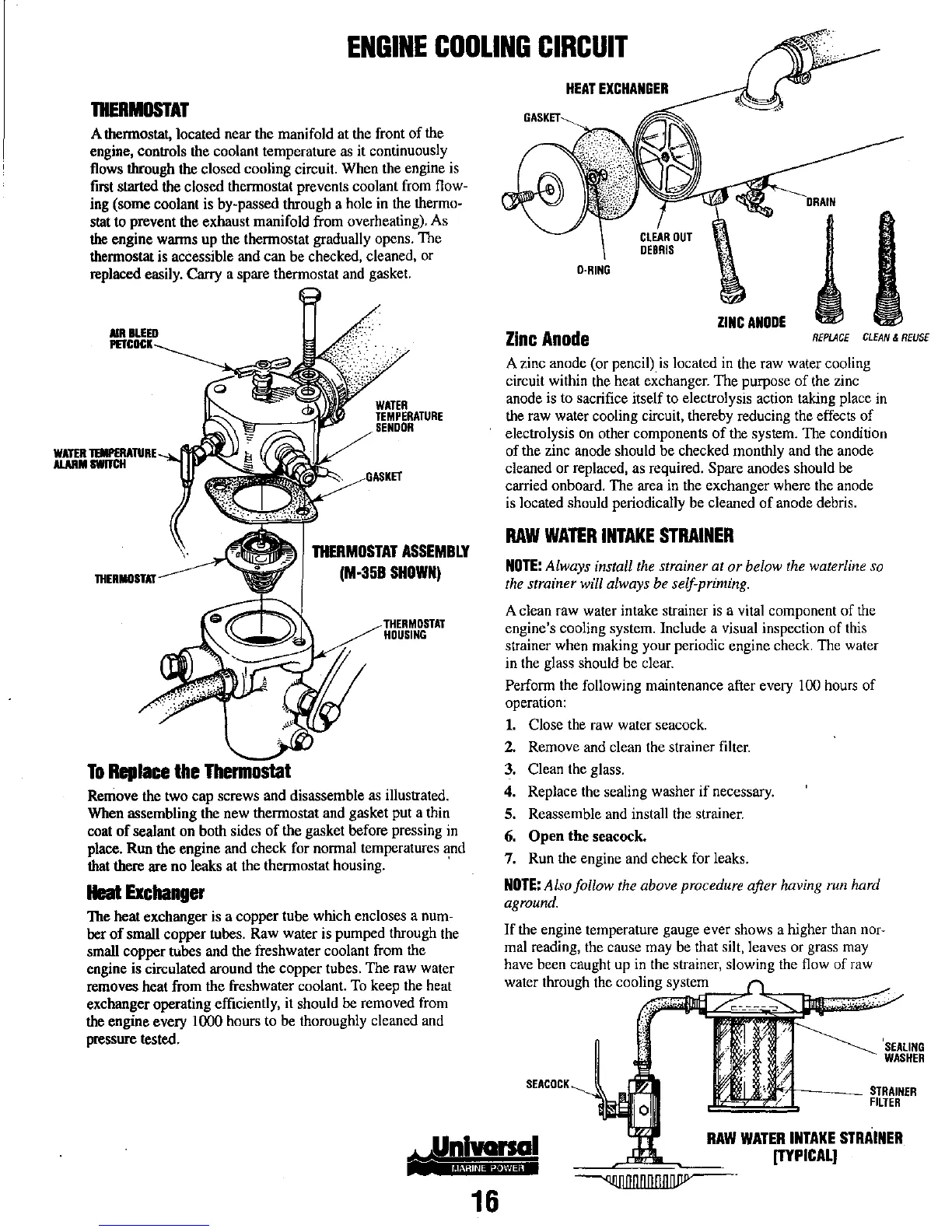

RAW

WATER

INTAKE

STRAINER

NOTE:

Always install

the

strainer at or below

the

waterline

so

the

strainer will always be self-priming.

A clean raw water intake strainer

is

a vital component

of

the

engine's cooling system. Include a visual inspection

of

this

strainer when making your periodic engine check. The water

in the glass should be clear.

Perfonn the following maintenance after every 100 hours

of

operation:

1.

Close the raw water seacock.

2. Remove and clean the strainer filter.

3.

Clean the glass.

4. Replace the sealing washer

if

necessary.

5.

Reassemble and install the strainer.

6.

Open

the

soacock.

7. Run the engine and check for leaks.

NOTE:

Also follow the above procedure after having

run

hard

aground.

If

the engine temperature gauge ever shows a higher than nor-

mal reading, the cause may be that silt, leaves

or

grass may

have been caught up in the strainer, slowing the flow

of

raw

water through the cooling system

SEACOCK

'SEALING

WASHER

:If':-t----

STRAINER

o!!£::::::l:2:f::!.

FILTER

RAW

WATER

INTAKE

STRAINER

[TYPICAL)

Loading...

Loading...