FUEL

SYSTEM

FUEL

ADDITIVES

If

fungus

or

bacteria

is

causing

fuel

problems,

you

should

have

an

authorized

dealer correct

these

problems.

Then

use

a diesel

fuel

biocide

to

sterilize

the

fuel

(follow

the

manufac-

turer's instructions).

SPARES

While

the

likelihood of having to service

the

fuel

system

at

sea

is

SUnil

the

possibility

does

exist.

Therefore,

we

recom-

mend

that

banjo

washers, injector seat washers,

and

a

fuel

fil-

ter

he

carried

on

board at all times. Purchase

needed

spares

from

your

local

UNNERSAL dealer or distributor.

If

a leak

should

develop at a banjo washer that cannot

be

corrected

by

a simple tightening of the fitting, replace

the

sealing

washer.

FUEL

LIFT

PUMP

The

on-engine

fuel

system

is

virtually self priming. Under

ordinary

circumstances the engine's electric

fuel

lift

pump,

which

is

energized

by

the

key

switch/preheat bulton,

will

"

supply

a continuous

flow

of

fuel

from

the tank. This

fuel

is

drawn

through

the

fueVwater

separator

to

the

engine lift

'pump,

the primary spin-on

fuel

fIlter,

and

the injection

pump.

A

WARNING:

0"

not

allow

smoking

or

open

flames

II/IaI

filii

tuBI

system

when

stmllclng.

Also

provide

proper

wmtIlatlon.

FUEL

SYSTEM

BLEEDING

.

If

it becomes necessary

to

bleed

air

from

the

on

engine

fuel

system,

tum

the

panel

key

ON

and

intennitently

5-

10

sec-

onds.

Activate

the

pre-hear

vircui!.

This activates

the

fuel

pump

which

draws

fuel

into

the

on

engine

fuel

system

and

drives

air out via

the

fuel

return.

If

high

pressure injector

lines

need

to

be

bled, loosen

the

injector line

nut

at

each

injector,

open

the

throttle

and

crank

the

engine over until

fuel

sports from between

the

nut

and

line.

the secure

the

nuts

and

start

the

engine

as

normal.

NOTE:

Do

'not

attempt

this

procedure on a hot

engine.

A

WARNING:

Always

wear

p!otectlvB

clothing,

samty

glasses

and

gloves

when

blBBdlng

high

pressure

injector/lnes.

TO

FUEL

19

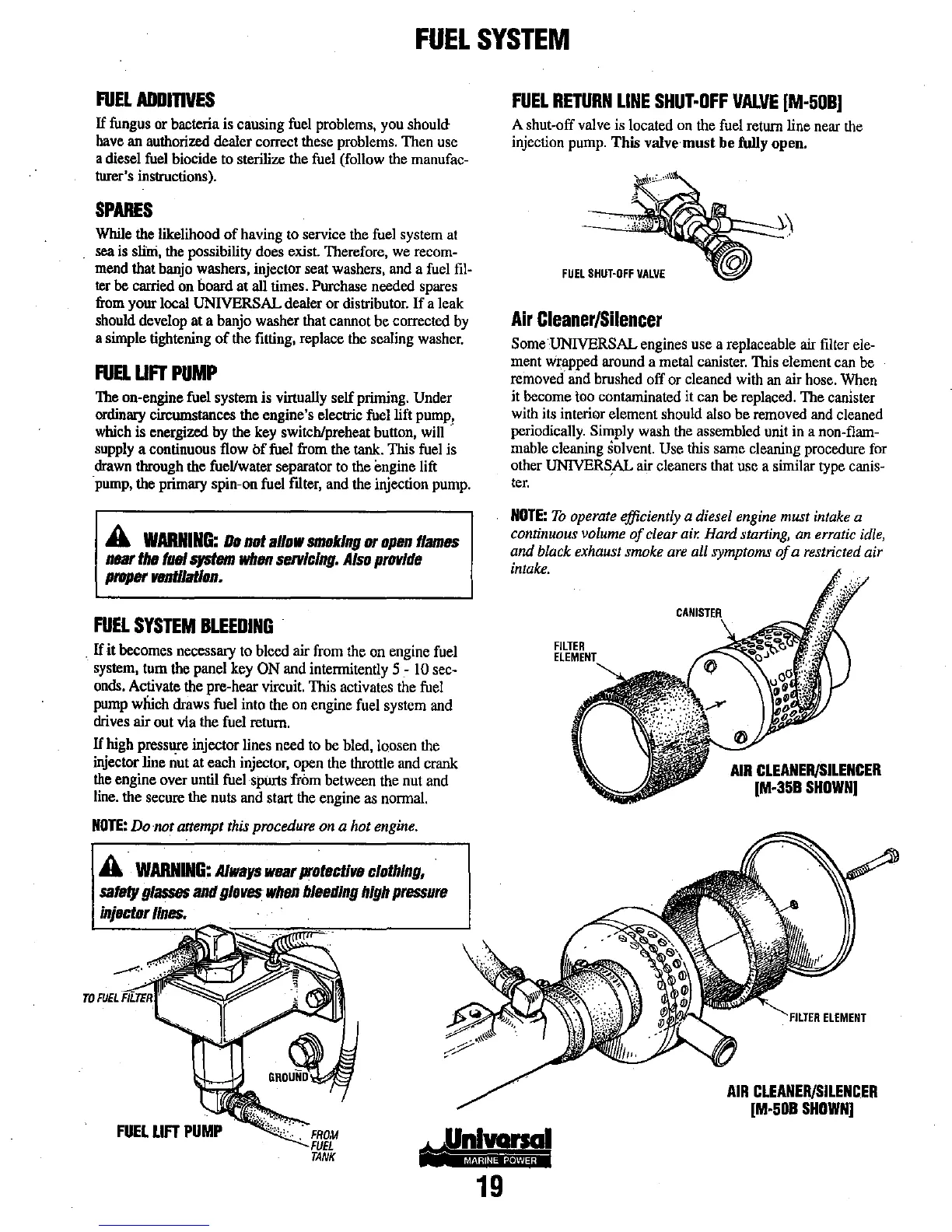

FUEL

RETURN

LINE

SHUT-OFF

VALVE

IM-SOBl

A shut-off

valve

is

located

on

the

fuel

retum line

near

the

injection

pump.

This valve must be fully open.

FUEl

SHUT-OFF

VALVE

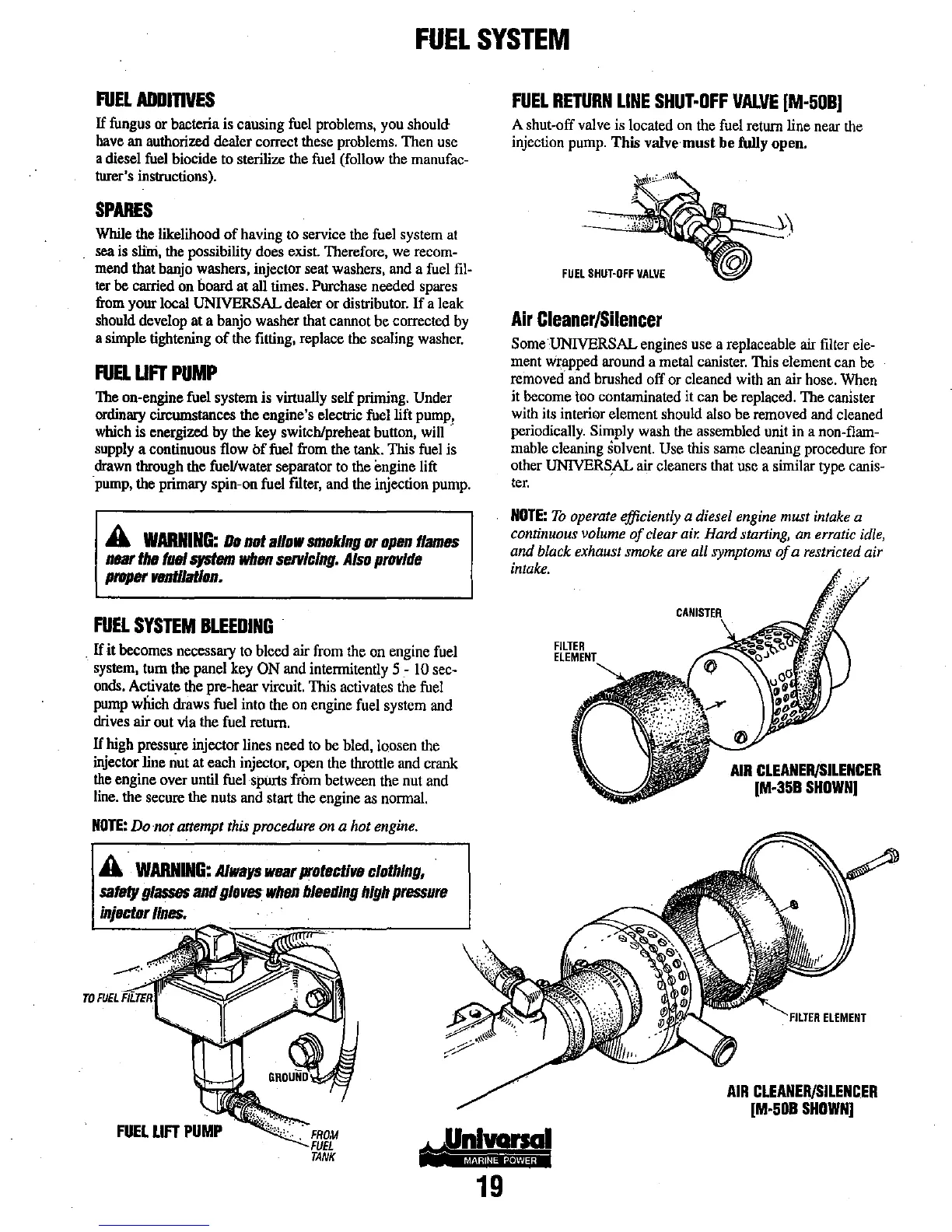

Air

Cleaner/Silencer

SomeUNNERSAL engines use a replaceable air

filter

ele-

ment

Wrapped

around a metal

canister.

1bis element

can

he

removed'

and

brushed

off

or

cleaned

with

an

air

hose.

When

it become

too

contaminated it can

he

replaced. The canister

with

its

interiQr

element should

also

be

removed

and

cleaned

periodically.

Simply

wash

the

assembled

unit

in

a

non-flam-

mable

cleaning

solvent.

Use

this

same

cleaning procedure

for

other

UNIVERSAL

air cleaners that

use

a similar

type

canis-

ter.

NOTE:

To

operate efficiently a diesel

engine

must

intake

a

continuous

volume

of

clear

air.

Hard

starting,

an

erratic

idle,

and black exhaust smoke

are

all symptoms

of

a restricted air

intake.

AIR

CLEANER/SILENCER

IM-35B

SHOWN)

ELEMENT

AIR

CLEANER/SILENCER

IM-50B

SHOWN]

Loading...

Loading...