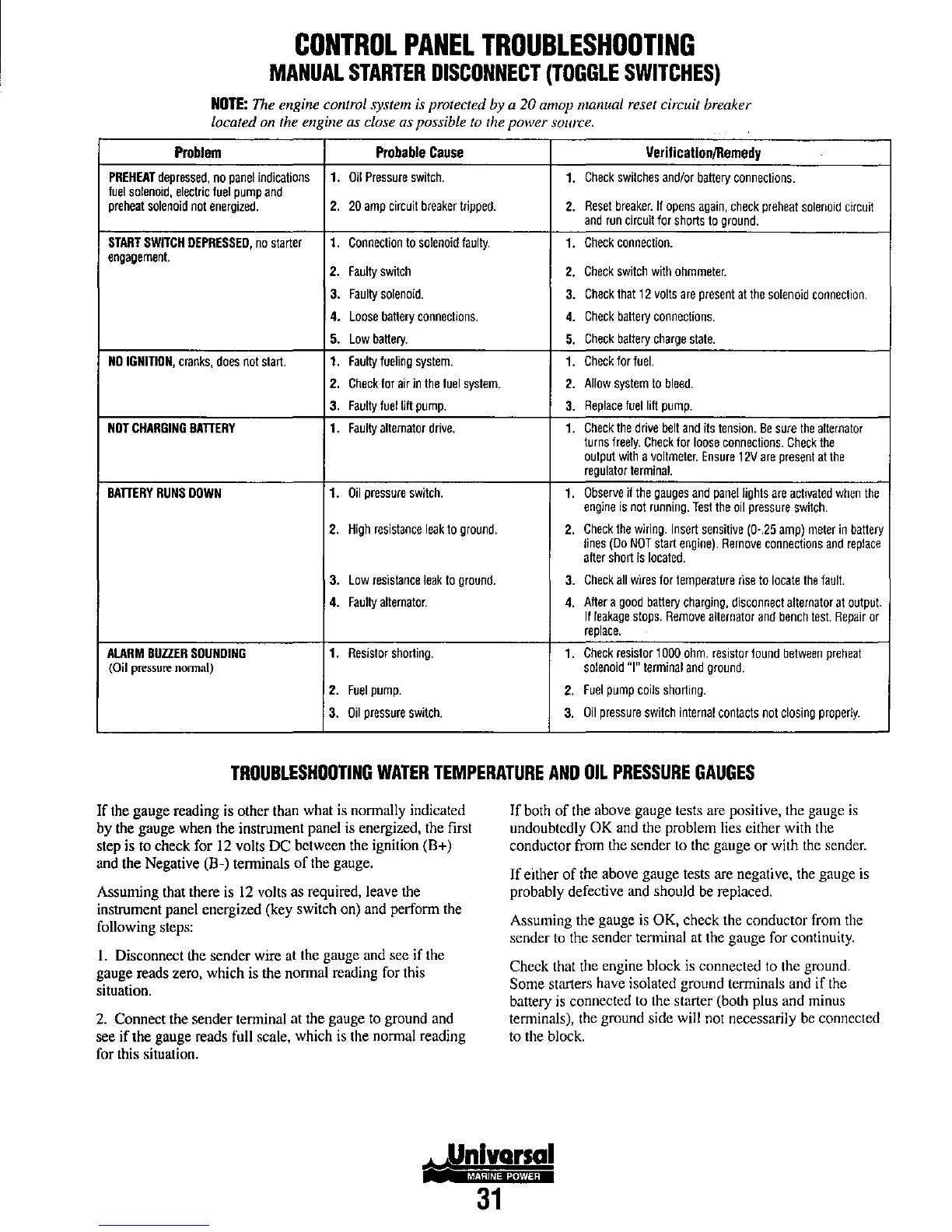

CONTROL

PANEL

TROUBLESHOOTING

MANUAL

STARTER

DISCONNECT

(TOGGLE

SWITCHES)

NOTE:

The engine control system is protected by a

20

amop manual reset circuit breaker

located on the engine as close as possible to the power source.

Problem

Probable

Cause

Verificallon/Remedy

PREHEAT

depressed.

no

panel

indications

1.

Oil

Pressure

switch.

1.

Check

switches

and/or

battery

connections.

fuel

solenoid,

electric

fuel

pump

and

preheat

solenoid

not

energized.

2.

20

amp

circuil

breaker

tripped.

2.

Reset

breaker.

If

opens

again,

check

preheat

solenoid

circuil

and

run

circuit

for

shorts

to

ground.

START

SWITCH

DEPRESSED.

no

starter

1.

Connection

to

solenoid

faulty.

1.

Check

connection.

engagement.

2.

Faulty

switch

2.

Check

switch

with

ohmmeter.

3.

Faulty

solenoid.

3.

Check

that

12

volts

are

present

at

the

solenoid

connection.

4.

Loose

battery

connections.

4.

Check

battery

connections.

5.

Low

batteI)'.

5.

Check

battel)'

charge

state.

NO

tGNITION.

cranks.

does

not

start.

1.

Faulty

fueling

system.

1.

Check

for

fuel.

2.

Check

for

air

in

the

fuel

system.

2.

Allow

system

to

bleed.

3.

Faulty

fuel

lift

pump.

3.

Replace

fuel

lift

pump.

NOT

CHARGING

BATTERY

1.

Faulty

alternator

drive.

1.

Check

the

drive

belt

and

its

tension.

Be

sure

the

alternator

turns

freely.

Check

for

loose

connections.

Check

the

output

with

a

voltmeter.

Ensure

12V

are

present

at

the

regulator

terminal.

BATTERY

RUNS

DOWN

1.

Oil

pressure

switch.

1.

Observe

if

the

gauges

and

panel

lights

are

activated

when

the

engine

is

not

running.

Test

the

oil

pressure

switch.

2.

High

resistance

leak

to

ground.

2.

Check

the

wiring.

Insert

sensitive

(0-.25

amp)

meter

in

bat1ery

lines

(Do

NOT

start

engine).

Remove

connections

and

replace

after

short

is

located.

3.

Low

resistance

leak

to

ground.

3.

Check

all

wires

for

temperature

rise

to

locate

the

fault.

4.

Faulty

alternator.

4.

After

a

good

bat1ery

charging,

disconnect

alternator

at

output.

If

leakage

stops.

Remove

alternator

and

bench

test.

Repair

or

replace.

ALARM

BUllER

SOUNDING

1.

Resistor

shorting.

1.

Check

resistor

1000

ohm.

resistor

found

between

preheat

(Oil

pressure nonnal)

solenoid

"I"

terminal

and

ground.

2.

Fuel

pump.

2.

Fuel

pump

coils

shorting.

3.

Oil

pressure

switch.

3.

Oil

pressure

switch

internal

contacts

not

closing

properly.

TROUBLESHOOTING

WATER

TEMPERATURE

AND

OIL

PRESSURE

GAUGES

If

the gauge reading is other than what is nonnally indicated

by the gauge when the instrument panel is energized, the first

step is to check for 12 volts

DC

between the ignition (B+)

and the Negative (B-) tenninals

of

the gauge.

Assuming that there is

12

volts as required, leave the

instrument panel energized (key switch on) and perfonn the

following steps:

1.

Disconnect the sender wire at the gauge and see if the

gauge reads zero, which is the nonnal reading for this

situation.

2. Connect the sender terminal at the gauge to ground and

see

if

the gauge reads full scale, which is the nonnal reading

for this situation.

31

If

both

of

the above gauge tests are positive, the gauge

is

undoubtedly

OK

and the problem lies either with the

conductor from the sender to the gauge

or

with the sender.

If

either

of

the above gauge tests are negative, the gauge is

probably defective and should be replaced.

Assuming the gauge

is

OK, check the conductor from the

sender to the sender tenninal at the gauge for continuity.

Check that the engine block is connected to the ground.

Some starters have isolated ground tenninals and if the

battery

is

connected to the starter (both plus and minus

tenninals), the ground side will not necessarily be connected

to the block.

Loading...

Loading...