DC

ELECTRICAL

SYSTEM

ENGINE

12

VOLT

DC

CONTROL

CIRCUIT

The engine has a

12

volt DC electrical control circuit that

is

shown on the wiring diagrams that follow. Refer

to

these dia-

grams when troubleshooting or when servicing the DC elec-

trical system on the engine.

DRIVE

BELT

ADJUSTMENT

A

CAUTION:

Drive

belts

must

be

properly

tensioned.

Looss

drille

belts

will

not

provide

proper

alternator

charging

and

will

eventually

damage

the

alternator.

DrllIB

belts

that

are

too

tight

will

pull

the

alternator

out

of

alignment

and/or

cause

the

alternator

to

wear

out

pre-

maturely.

Belt tension adjustment is made by pivoting the alternator on

· its base mounting bolt.

1.

Loosen the alternator adjusting strap bolt and the base

mounting bolt.

2.

Pivot the alternator on the base mounting bolt

to

the left

or

right

as

required.

3. Tighten the base mounting bolt and the adjusting strap

bolt.

4. Operate the engine for about 5 minutes at idle, then shut

down and recheck belt tension.

/'<-

~

BATTERY

CARE

Review

the

manufacturer's

recommendations

and

then

establish a systematic

maintenance

schedule

for

your

engine

starting

batteries

and

house

batteries.

• Monitor your voltmeter for proper charging during engine

operation.

• Check

the

electrolyte level and specific gravity with a

hydrometer.

• Use only distilled water

to

bring electrolytes

to

a proper

level.

• Make certain that battery cable connections are clean and

tight to

the

battery posts (and to your engine).

•

Keep

your

batteries

clean

and

free

of

corrosion.

21

GLOW

PLUGS

The glow plugs are wired through the preheat solenoid.

When

PREHEAT

is

pressed at the control panel this solenoid

should

"click" on and the glow plug should begin

to

get hot.

Inspection

To

inspect the plug, remove the electrical terminal connec-

tions, then unscrew or unclarnp each plug from the cylinder

head. Thoroughly clean each plug's tip and threads with a

soft brush and cleaning solution

to

remove

all

the carbon and

oil

deposits. While cleaning, examine the tip for wear and

burn erosion; if

it

has eroded too much, replace the plug.

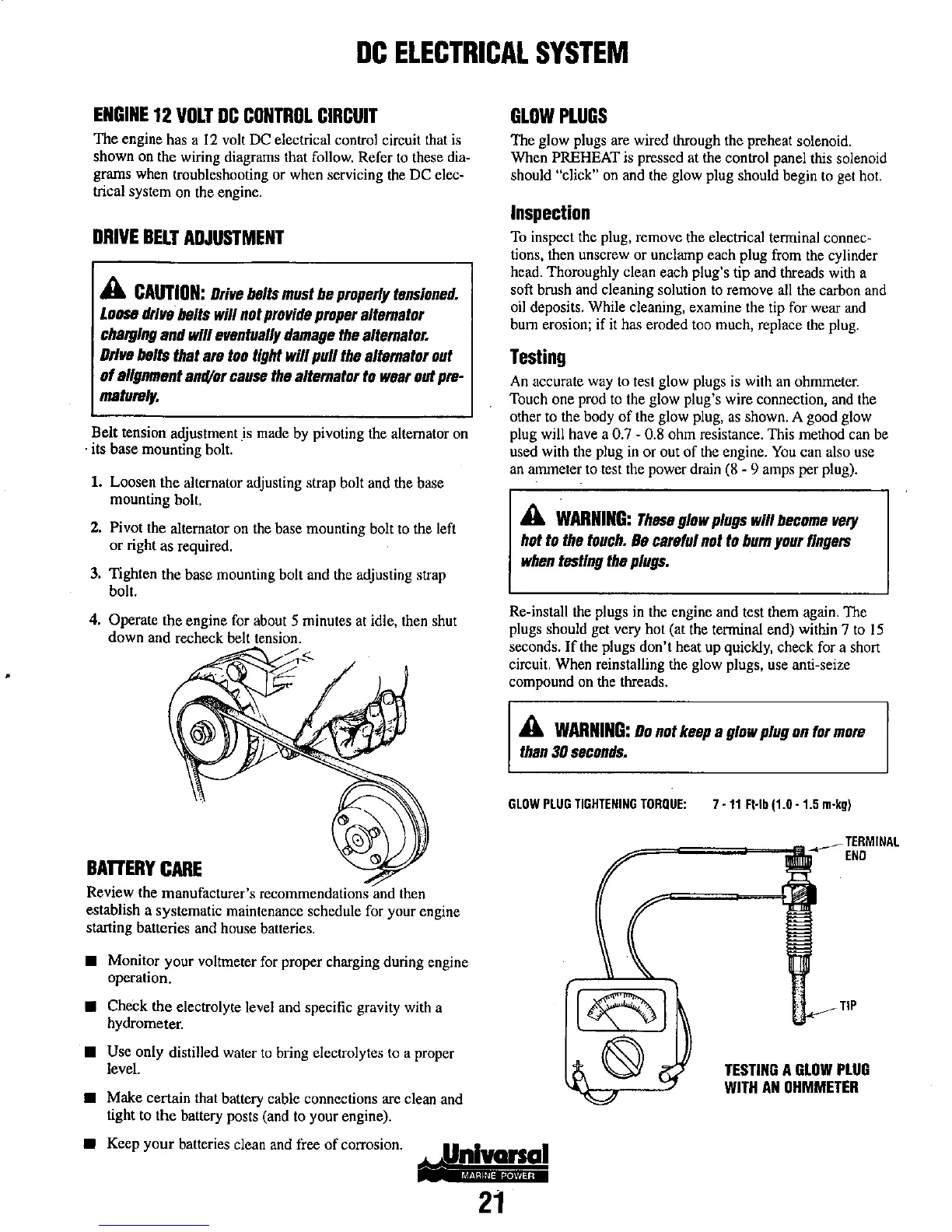

Testing

An accurate way to test glow plugs

is

with an ohmmeter.

Touch one prod

to

the glow plug's wire connection, and the

other to the body

of

the glow plug,

as

shown. A good glow

plug will have a

0.7 - 0.8 ohm resistance. This method can be

used with the plug in or out

of

the engine.

You

can also use

an

ammeter to test the power drain

(8

- 9 amps per plug).

.

A

WARNING:

These

glow

plugs

will

become

very

hot

to

the

touch.

Be

careful

not

to

bum

your

fingers

when

testing

the

plugs.

Re-install the plugs in the engine and test them again. The

plugs should get very hot (at the terminal end) within 7

to

15

seconds.

If

the plugs don't heat up quickly, check for a short

circuit. When reinstalling the glow plugs, use anti-seize

compound

on

the

threads.

A

WARNING:

00

not

keep

a

glow

plug

on

for

more

than

30

seconds.

GLOW

PLUG

TIGHTENING

TORQUE:

7 ·11

Ft·lb

(1.0·

1.5

m·kg)

TERMINAL

END

TIP

TESTING

A

GLOW

PLUG

WITH

AN

OHMMETER

Loading...

Loading...