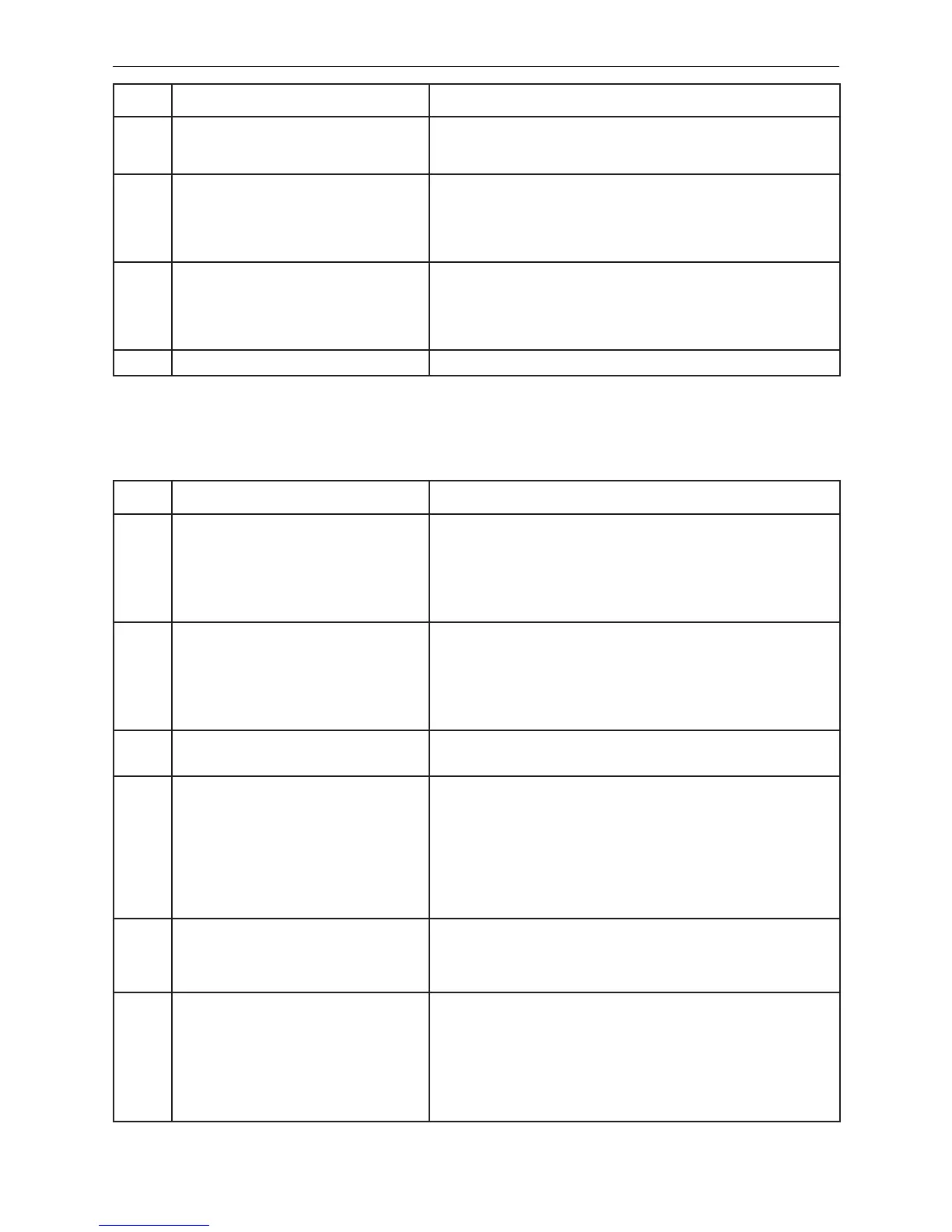

32

4. Troubleshooting

Code Display on InfoWIN Cause/remedy

FE 372

Starting report

Temperature in combustion chamber too low

during heating up.

Heating up performed with damp and/or poor quality wood. Heating up pro-

cess not performed according to the instructions. Press the Reset button.

FE 373

Starting report

Power consumption too low during heating up.

Ensure enough heat is consumed (open manual mixing valve, set control

system to heating requirement/heating mode). Press the Reset button.

Important: If the control system is not demanding any heat (reducing de-

mand) and the hot water tank or accumulator tank is up to temperature

– Do not heat up!

FE 375

Heating up at excessively high boi-

ler temperature

Press reset.

Ensure enough heat is consumed (open manual mixing valve, set control

system to heating requirement/heating mode). Press the Reset button.

Important: If the control system is not demanding any heat (reducing de-

mand) and the hot water tank or accumulator tank is up to temperature

– Do not heat up!

FE 396 Cladding door open

Close the cladding door.

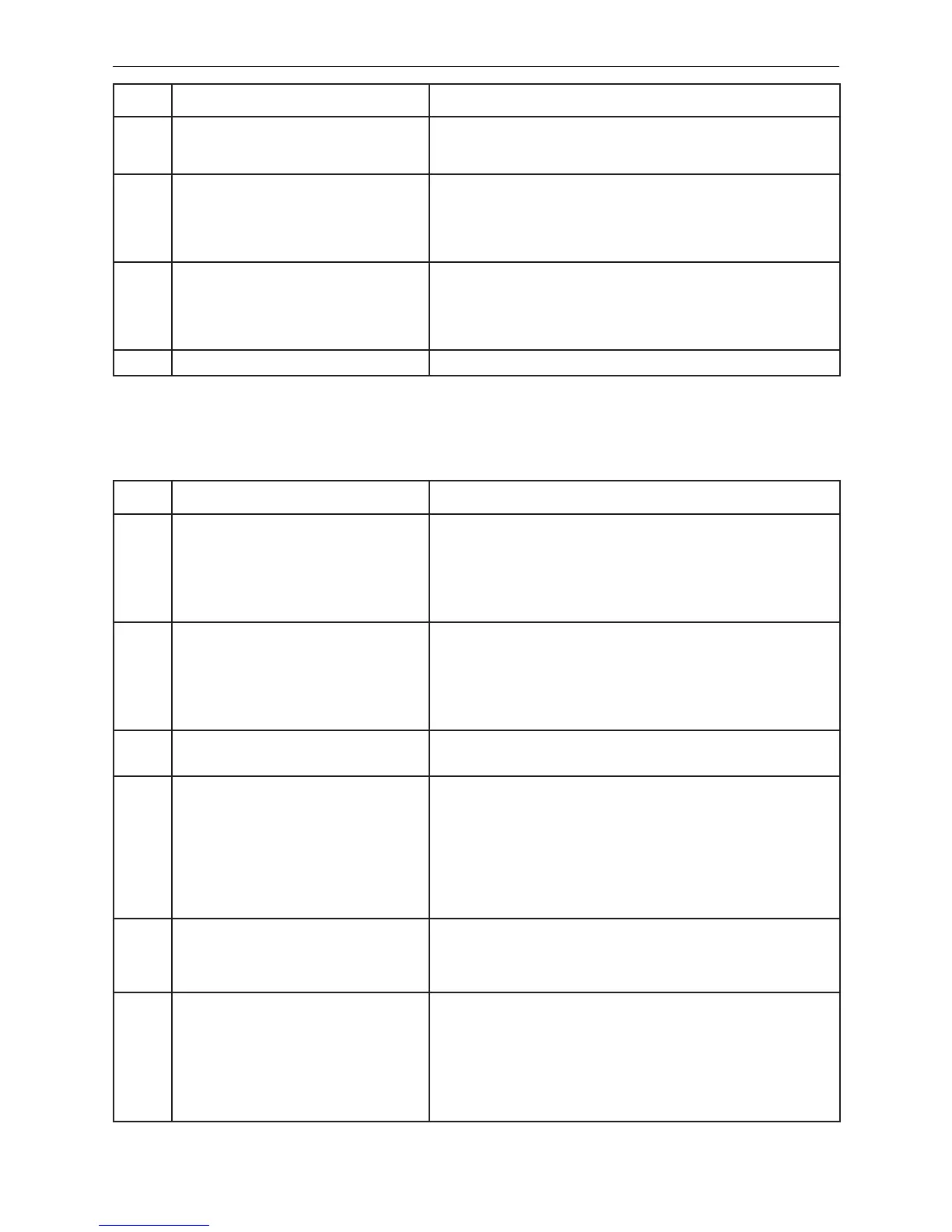

4.3 AL – messages

Code Display on InfoWIN Cause/remedy

AL 001

Primary airflap defect

Primary airflap blocked or defect.

The primary airflap is no longer reaching its position. Primary airflap mo-

tor or limit switch defect.

Press the Reset button. If the fault reoccurs after a rest, inform Windhager

Customer Service or a heating technician.

Replace the primary airflap motor or limit switch, inform Windhager Cus-

tomer Service or a heating technician.

AL 003

Secondary airflap defect

Secondary airflap blocked or defect.

The secondary airflap is no longer reaching its position. Secondary airflap

motor or limit switch defect.

Press the Reset button. If the fault reoccurs after a rest, inform Windhager

Customer Service or a heating technician.

Replace the secondary airflap motor or limit switch, inform Windhager

Customer Service or a heating technician.

AL 015

230V not reached

Press reset.

There is no 230 V mains voltage for the automatic firing device.

Inform Windhager Customer Service or a heating technician.

AL 016

Induced draught fan defective

Clean blower wheel and blower box.

Press reset.

The actual speed is different from the nominal speed. The boiler switches-

to burnout mode.

a) The blower wheel and blower box are dirty, clean (see section 3.3.2).

Press the Reset button.

b) Blower plug loose or not snapped in, firmly connect plug (on rear wall

of boiler).

c) Replace the induced draught fan motor, inform Windhager Customer

Service or a heating technician.

AL 076

Boiler sensor defective

Check the boiler sensor and connections.

Press reset.

a) Press the Reset button. If this malfunction occurs again, contact Wind-

hager Customer Service or a heating technician.

b) Replace the boiler sensor, inform Windhager Customer Service or a

heating technician.

AL 078

Thermocontrol sensor defective

Check the Thermocontrol sensor and con-

nections. Press reset.

The boiler switches to burnout mode.

a) Thermocontrol sensor is too cold < 0 °C. Sensor warm up.

b) Press the Reset button. If the malfunction recurs immediately after a

short period, or recurs at regular intervals, contact Windhager Custo-

mer Service or your heating technician.

c) Renew the thermocontrol sensor, inform Windhager Customer Service

or a heating technician..

Loading...

Loading...