14 3062555_201804

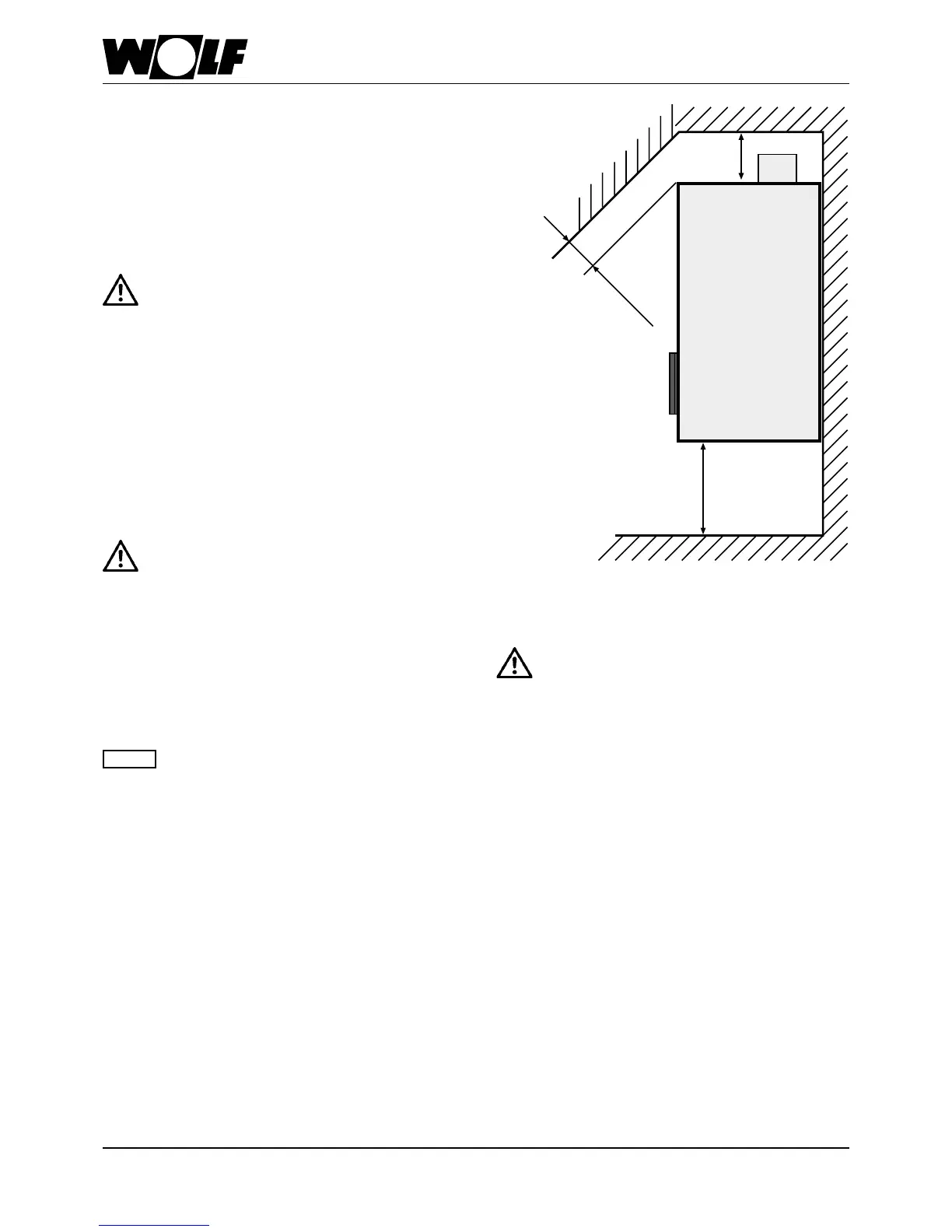

First determine where the appliance is to be installed.

For this, take into account the ue gas connection, lateral

clearances towards walls and the ceiling, and any existing

connectionsforgas,heating,DHWandelectrics.

7. Sitinginstructions

Sound insulation: Under certain critical installation conditions

(e.g. installation on a drywall), additional measures may be

necessary to soundproof the boiler. In such conditions, use

anti-vibration rawl plugs and, if necessary, rubber mounts or

insulation strips.

When using a

low loss header set

Min. 830 mm

Min.

350 mm

Min.

350 mm

Electrical connection must be made on site.

Please maintain the 350 mm clearance to the ceiling to enable

inspection and maintenance work on the boiler to be carried

out, otherwise the necessary inspection and function tests

on components cannot be ensured during maintenance. The

drain hoses must be secured with the retainer above the drain

outlet (trap). The drain must be able to be easily inspected.

Theboilermaybeinstalledonlyinrooms

thatareprotectedfromfrost.

The temperature in the installation room must be be-

tween 0°C and 40°C.

Generalinformation

Clearancebetweentheboilerandcombustible

materials or components is not required, as

temperatureswillnotexceed85°Cattherated

boiler heating output. However, explosive or

readilyammablematerialsmustnotbeused

intheinstallationroomasthiswouldcreatea

riskofreorexplosion.

Duringboilerinstallation,ensurethatnocon-

taminants (e.g. drilling swarf) enter the gas

boiler,otherwisefaultsmaydevelop.

Note

Theinstallationroomandthecombustionair

supplied to the appliance must be free from

chemicals, e.g. uorine, chlorine or sulphur.

These substances are contained in sprays,

paints, adhesives, solvents and cleaning

agents.Underunfavourableconditions,these

mayleadtocorrosion,includingintheuegas

system.

Loading...

Loading...